Method for reducing specific resistance of concentrated sludge

A technology of concentrated sludge and sludge specific resistance, which is applied in dehydration/drying/concentrated sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of unsatisfactory effect and high sludge specific resistance, and achieve Reduce deformation, reduce treatment costs, and reduce the effect of sludge specific resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

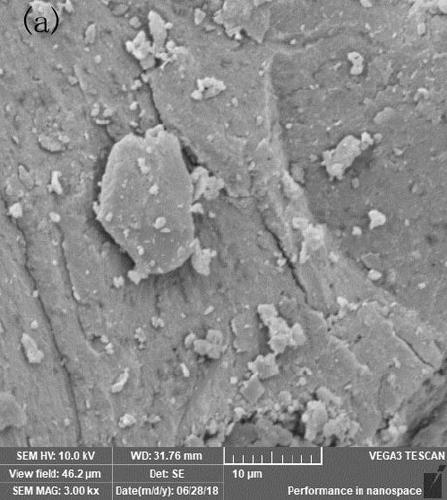

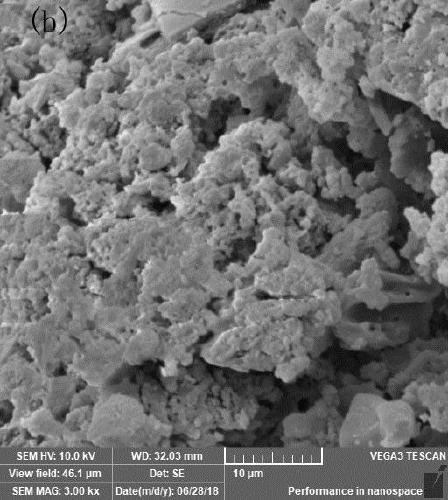

Image

Examples

Embodiment 1

[0021] (1) Concentrate the mixed sludge produced by wastewater treatment to a solid content of more than 5% by air flotation or sedimentation, and perform anaerobic digestion treatment to control the digestion process in the hydrolysis and acidification stage, so that part of the organic matter in the sludge is fermented to produce organic acids, so that The pH of the digestive juice is continuously reduced to 3.87, and the ionization of the organic acid generates hydrogen ions, which inhibit the subsequent ionization of the water-soluble groups of the pH and temperature-responsive polyacrylate polymer copolymer;

[0022] (2) Pump the sludge after anaerobic digestion into the reaction tank, and add soft monomer, hard monomer and acrylic monomer with a glass transition temperature (Tg) of 70°C to the sludge in proportion while stirring The amine (or ammonium) salt of the pH- and temperature-responsive polyacrylate polymer copolymer formed by copolymerization, the dosage is 0.4g / ...

Embodiment 2

[0028] (1) Concentrate the mixed sludge produced by wastewater treatment to a solid content of more than 5% by air flotation or sedimentation, and perform anaerobic digestion treatment to control the digestion process in the hydrolysis and acidification stage, so that part of the organic matter in the sludge is fermented to produce organic acids, so that The pH of the digestive juice is continuously reduced to 4.0, and the ionization of the organic acid generates hydrogen ions, which inhibit the subsequent ionization of the water-soluble groups of the pH and temperature-responsive polyacrylate polymer copolymer;

[0029] (2) Pump the sludge after anaerobic digestion into the reaction tank, and add soft monomer, hard monomer and acrylic monomer with a glass transition temperature (Tg) of 70°C to the sludge in proportion while stirring The amine (or ammonium) salt of the pH- and temperature-responsive polyacrylate polymer copolymer formed by copolymerization, the dosage is 0.3g / g...

Embodiment 3

[0035] (1) Concentrate the mixed sludge produced by wastewater treatment to a solid content of more than 5% by air flotation or sedimentation, and perform anaerobic digestion treatment to control the digestion process in the hydrolysis and acidification stage, so that part of the organic matter in the sludge is fermented to produce organic acids, so that The pH of the digestive juice is continuously reduced to 4.0, and the ionization of the organic acid generates hydrogen ions, which inhibit the subsequent ionization of the water-soluble groups of the pH and temperature-responsive polyacrylate polymer copolymer;

[0036](2) Pump the sludge after anaerobic digestion into the reaction tank, and add soft monomer, hard monomer and acrylic monomer with a glass transition temperature (Tg) of 70°C to the sludge in proportion while stirring The amine (or ammonium) salt of the pH- and temperature-responsive polyacrylate polymer copolymer formed by copolymerization, the dosage is 0.2g / g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com