AIOps intelligent operation and maintenance system based on artificial intelligence technology

An artificial intelligence and operation and maintenance system technology, applied in the field of operation and maintenance management, can solve problems such as fault location difficulties, analysis, inability to realize cross-domain, cross-platform monitoring, health detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

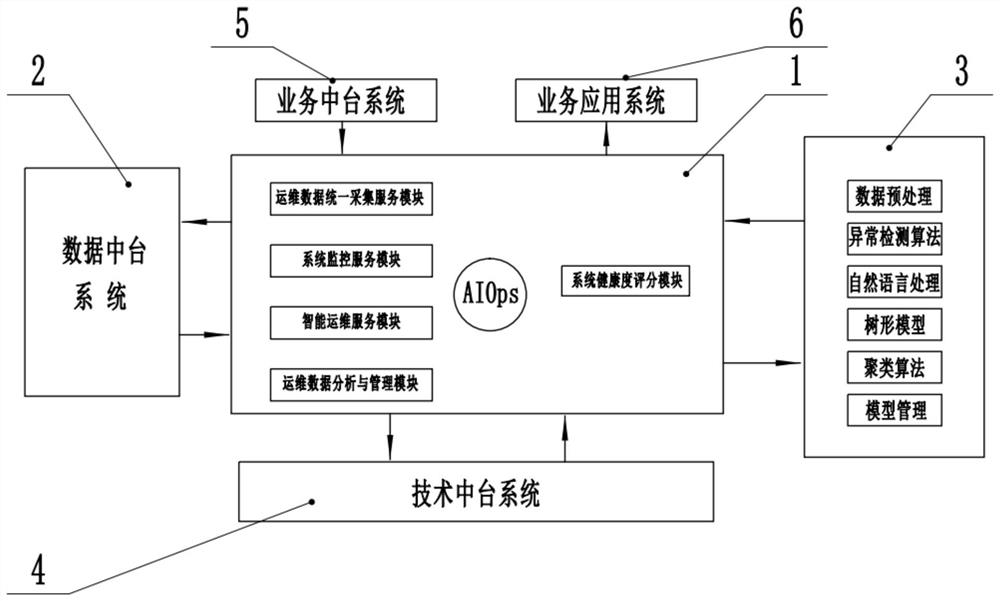

[0034] System Health Score

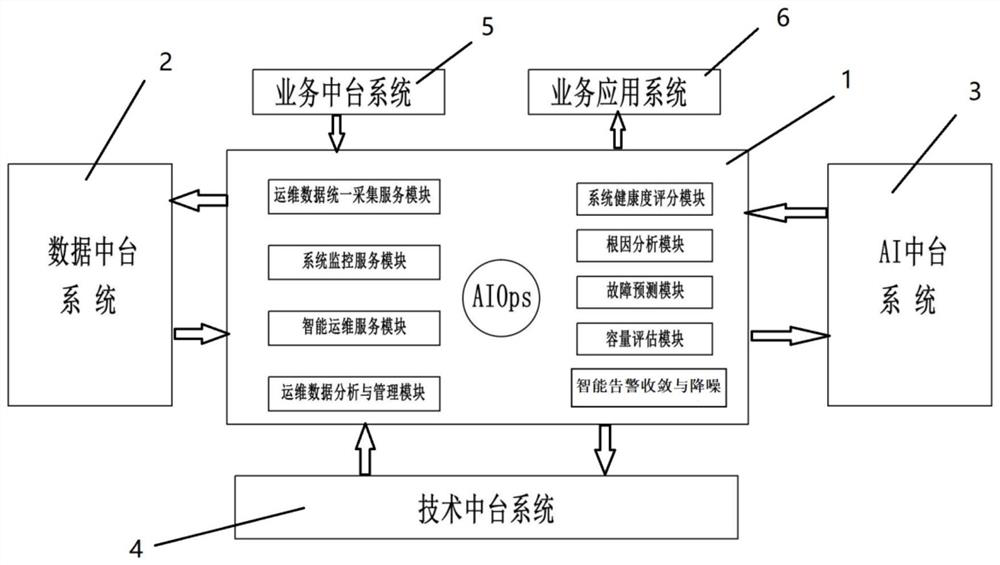

[0035] see figure 1 and figure 2 , AIOps intelligent operation and maintenance system based on artificial intelligence technology, including AIOps intelligent operation and maintenance center system 1, data middle platform system 2, AI middle platform system 3, technology middle platform system 4, business middle platform system 5 and business application system 6, The two-way connection and transmission between the AIOps intelligent operation and maintenance center system 1 and the data middle platform system 2, the two-way connection and transmission between the intelligent operation and maintenance center system 1 and the AI middle platform system 3, and the two-way connection and transmission between the intelligent operation and maintenance center system 1 and the technology middle platform system Two-way connection and transmission between 4, and one-way connection and transmission between business middle platform system 5 and business ap...

Embodiment 2

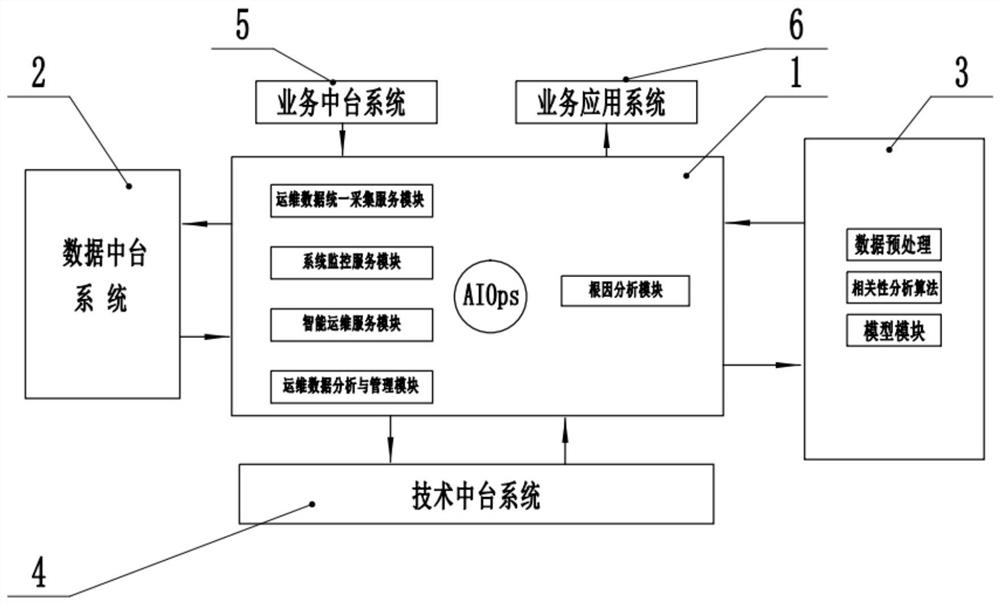

[0042] root cause analysis

[0043] see figure 1 and image 3 Compared with Embodiment 1, the intelligent operation and maintenance center system 1 also includes a root cause analysis module, and the AI middle platform system 3 includes a data preprocessing module, a correlation analysis algorithm module and a model module, according to the call chain and multiple Index correlation analysis, analyze the data in real time, update the data model and causal relationship, and the causal analysis results can quickly locate the object and index of the problem. Identify the causal relationship based on the time series and dimensions of different instances (such as including the causal relationship between host instances and the causal relationship between different indicators within the host instance), and present it through a drill-down causal topology to help effectively Determine and locate the root cause of the failure. Assist the operation and maintenance personnel to quick...

Embodiment 3

[0045] failure prediction

[0046] see figure 1 and Figure 4 Compared with Embodiment 2, the intelligent operation and maintenance center system 1 also includes a fault prediction module, and the AI middle platform system 3 includes a data preprocessing module, a correlation analysis algorithm module, a triple exponential smoothing algorithm, and a tree regression algorithm And the model management module collects massive data such as performance indicators and application logs, reuses the capabilities of data center analysis and AI middle stage prediction model training, and forms trend predictions for key operation and maintenance indicators. Combined with business call chains, abnormal Causality and expert rules are used to predict and analyze faults and warn in advance, so as to discover problems before users, lay a solid foundation for solving problems before complaints, and avoid production impacts caused by faults.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com