Equipment and process method for producing active organic fibers

An organic fiber and active technology, applied in the field of fiber manufacturing, can solve the problems of low friction between fibers, low production efficiency, instability, etc., and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

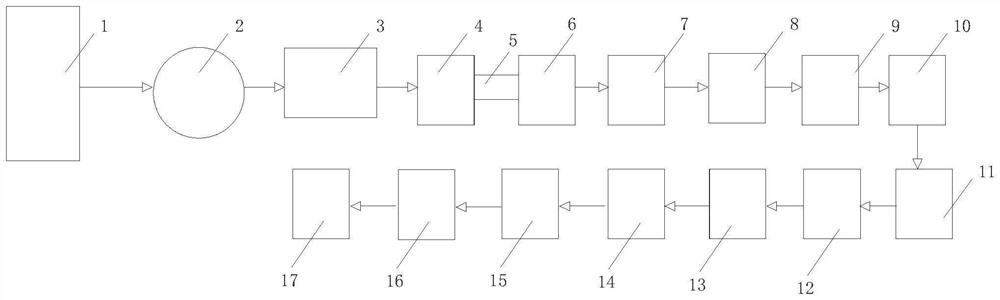

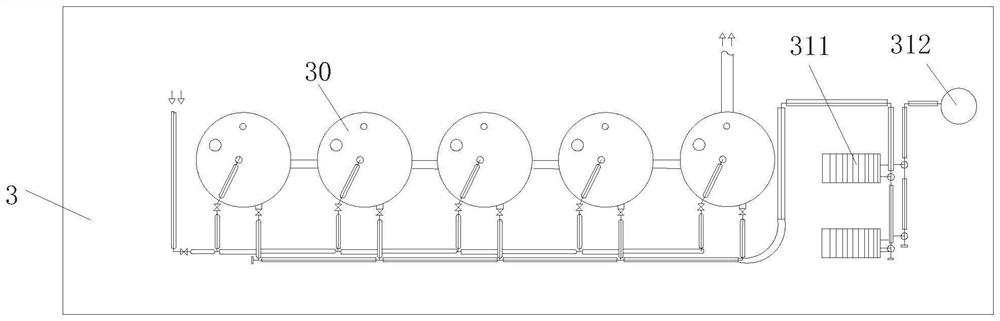

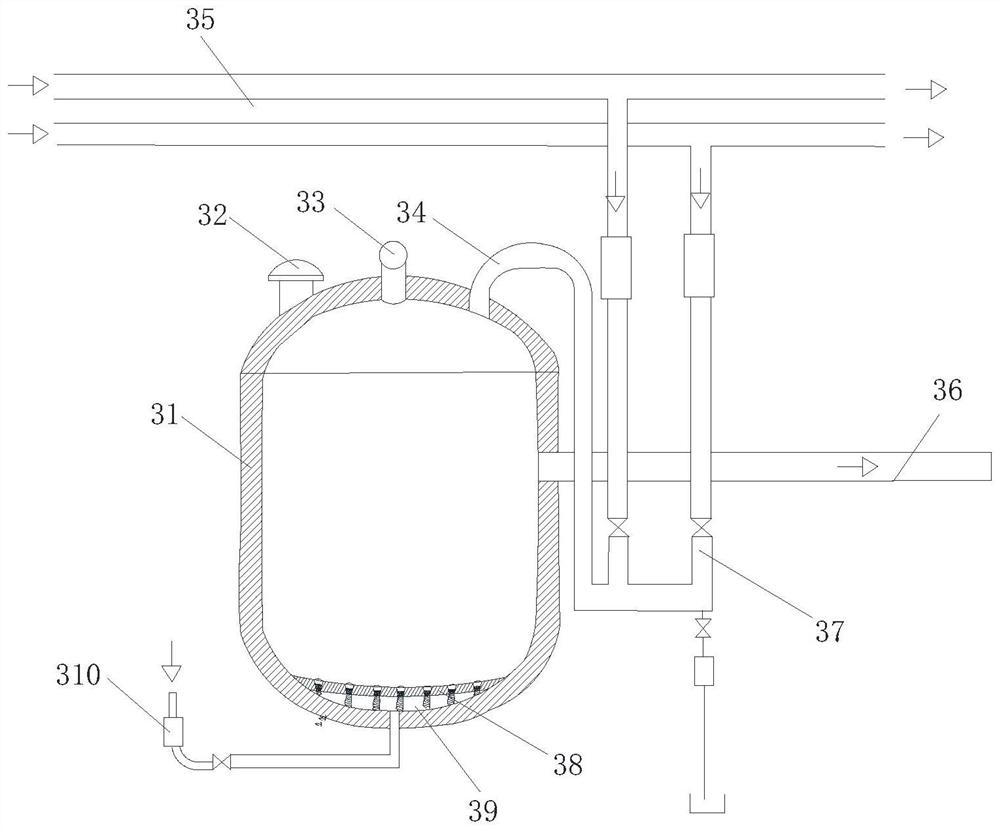

[0047] like figure 1 As shown, the present invention provides a device for producing active organic fibers, comprising a control device, a pneumatic device, a power supply device and an extraction tank 1, a dissolving tank 2, a defoaming device 3, a coloring tank that are connected in sequence through a process sequence. 4. Wet heat extension machine 6, dryer 7, dry heat extension machine 8, shrinkage cooler 9, winder 10, cutter 11, short fiber crimping pool 12, color fixing pool 13, oiling device 14 and baler 15. The defoaming device 3 includes a plurality of defoaming tanks 30 that communicate with each other, and a forming and solidifying tank 5 is provided between the coloring tank 4 and the moist heat stretching machine 6 . like figure 2 and 3 As shown, the specific structure of the defoaming tank 30 in the defoaming device 3 includes a tank body 31 and a cover body that are hermetically connected to each other. 34. When the pressure inside the tank 31 reaches the set...

Embodiment 2

[0068] like Figure 8-9 As shown, this embodiment is further improved on the basis of Embodiment 1, the difference is that: in an active organic fiber production equipment provided in this embodiment, the forming and coagulation tank 5 includes a tank body 56 with a tank cavity 51 , the coagulation bath liquid is placed in the cavity 51 of the tank, and the active organic fiber stock solution is transported to the candle filter by the metering pump 55 and then sent to the spinneret 58 by pressure. The organic fiber filaments are sprayed out, and the spinning 52 corresponding to the thickness is formed in the coagulation bath. In order to have as many scars as possible on the spinning 52, the groove body 56 is provided with a second vertical direction perpendicular to the front of the spinneret 58 on any outside. Two motors 510, the second rotating shaft 511 of the second motor 510 is provided with gears 59 fixedly mounted through the shaft holes 591, and the teeth 592 on each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com