Oxygen lance nozzle and blowing smelting method thereof

A technology of an oxygen lance nozzle and a smelting method, applied in the direction of manufacturing converters, etc., can solve the problems of affecting the iron yield, low dephosphorization efficiency of molten steel, and high residual iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

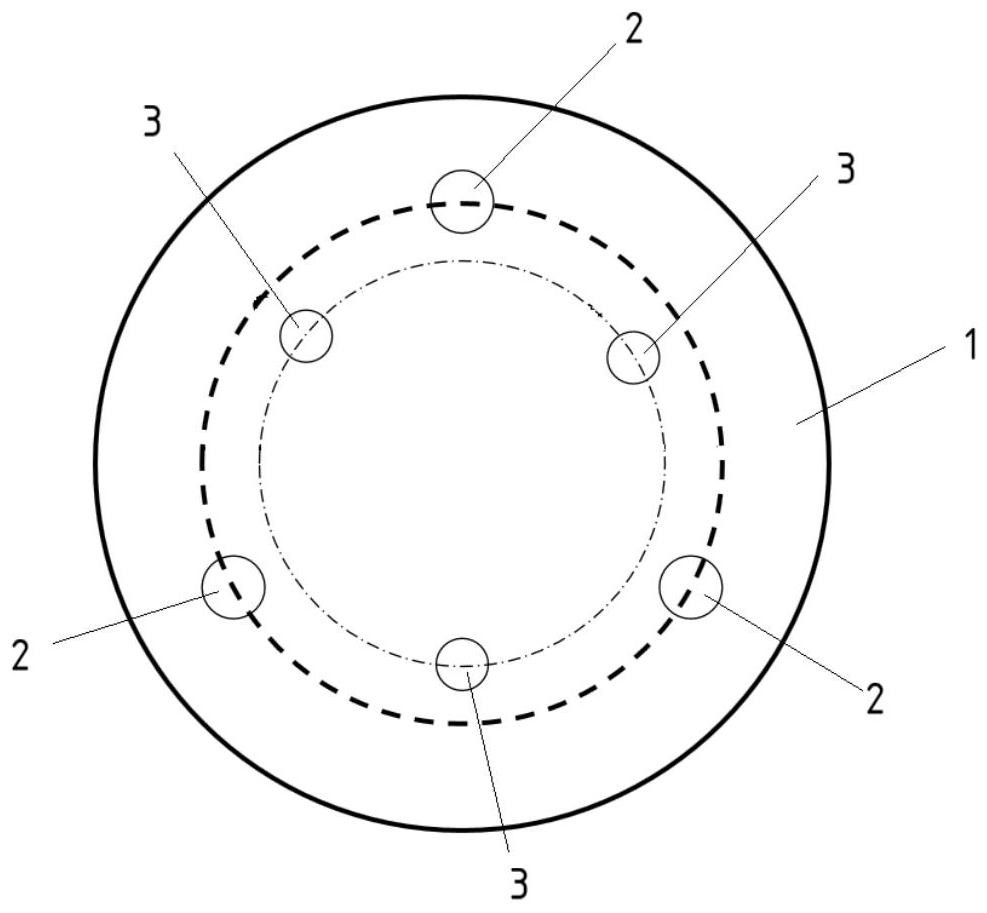

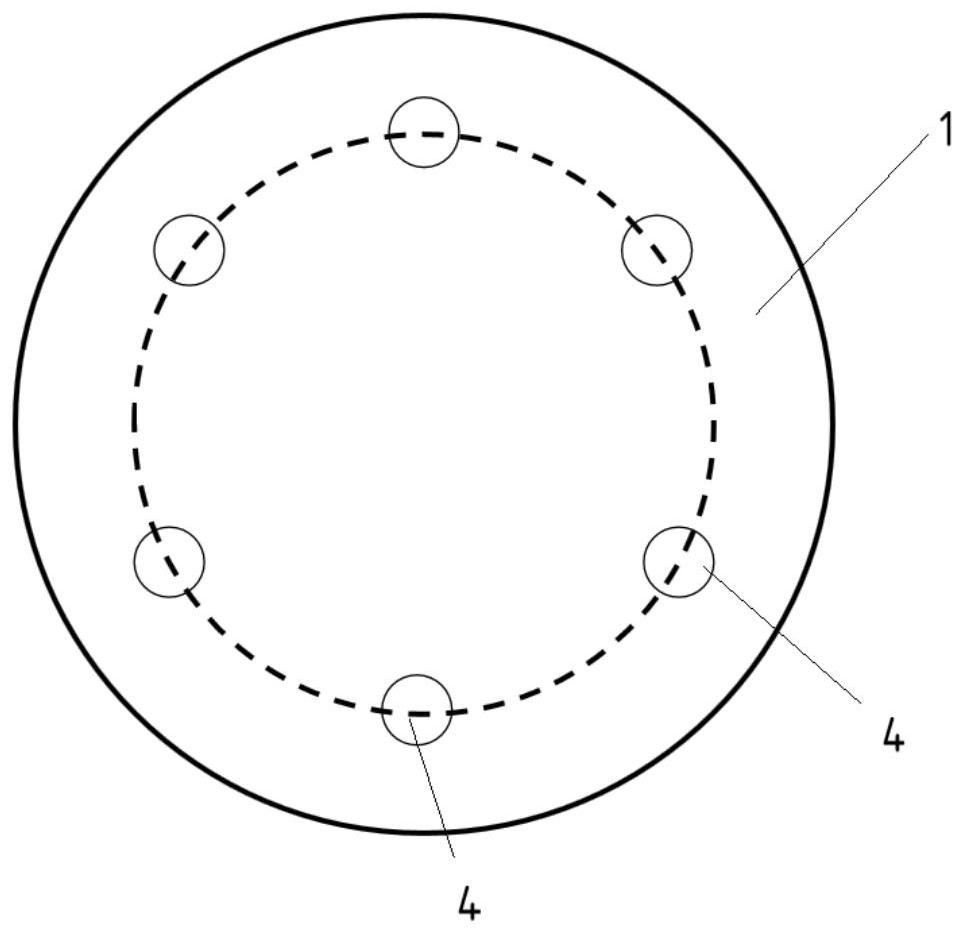

[0052] Embodiment 1 provides an oxygen lance nozzle, which is provided with 3 large holes and 3 small holes, the throat diameter of the large holes is 45.3mm, the central inclination angle is 15.5°, the Mach number is 2.05, and the distribution circle diameter is 0.56 D, the large hole corresponds to the jet flow outward, and the jet O 2 ; The throat diameter of the small hole is 36.6mm, the center inclination angle is 11.5°, the Mach number is 2.15, the diameter of the distribution circle is 0.52D, the small hole corresponds to the jet flow inward, and the CO injection 2 +O 2 Mixed gas, among them, CO 2 The volume fraction of oxygen is 10%, and the volume fraction of oxygen is 90%.

[0053] The oxygen lance nozzle is used to spray and smelt the molten iron in the converter. The capacity of the converter is 300t, the loading capacity of molten iron is 275t, the loading capacity of scrap steel is 60t, the total flow rate of the three large holes is 40000Nm3 / h, and the three s...

Embodiment 2

[0055] Embodiment 2 takes embodiment 1 as a reference, and the difference between embodiment 2 and embodiment 1 is that the volume fraction of carbon monoxide is 20% in embodiment 2, and the flow rate of the mixed gas injected by the large hole is 38000Nm 3 / h, the flow rate of the mixed gas injected by the small hole is 220000Nm 3 / h.

Embodiment 3

[0057] Embodiment 3 is with reference to embodiment 1, and embodiment 3 is different from embodiment 1, and the central inclination angle of large hole is 14 ° in embodiment 3, and the central inclination angle of small hole is 10.5 °, and the throat diameter of large hole is 42mm, the throat diameter of the small hole is 33mm, and the volume fraction of carbon monoxide in the mixed gas injected from the small hole is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com