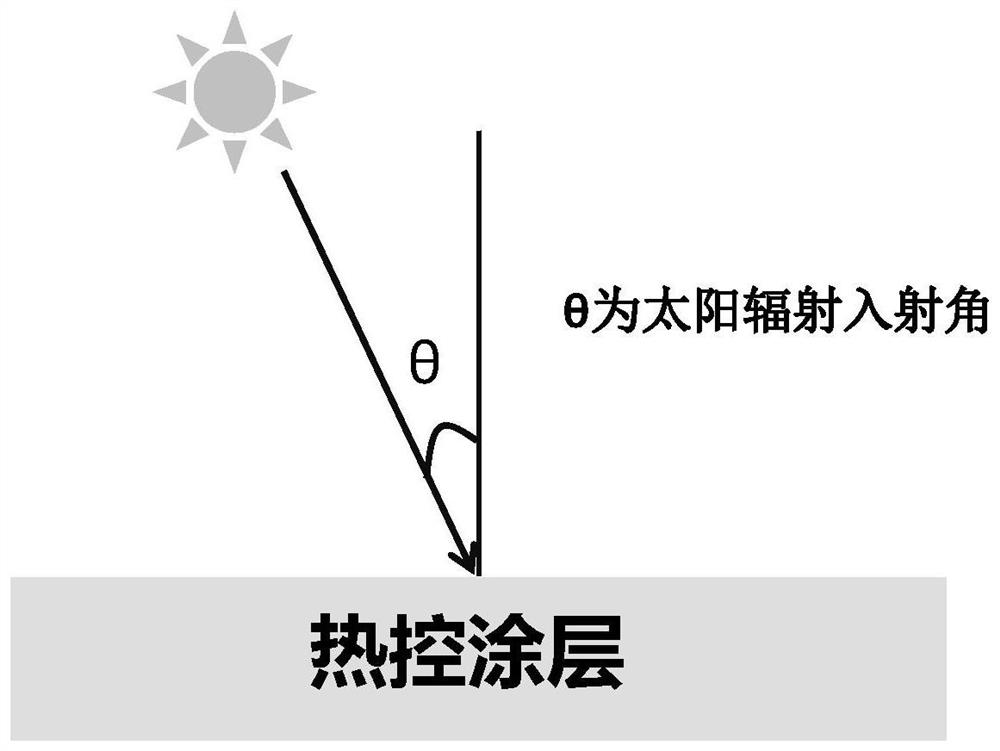

Low-absorption and low-emission thermal control coating with solar absorption ratio changing along with incident angle and preparation method of low-absorption and low-emission thermal control coating

A solar absorption ratio and thermal control coating technology, which is applied in the direction of radiation-absorbing coatings, coatings, metal-free paints, etc., can solve the problem of reduced heat flow input, lower temperature, and affecting the high-precision thermal control performance of the spacecraft surface and structural precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

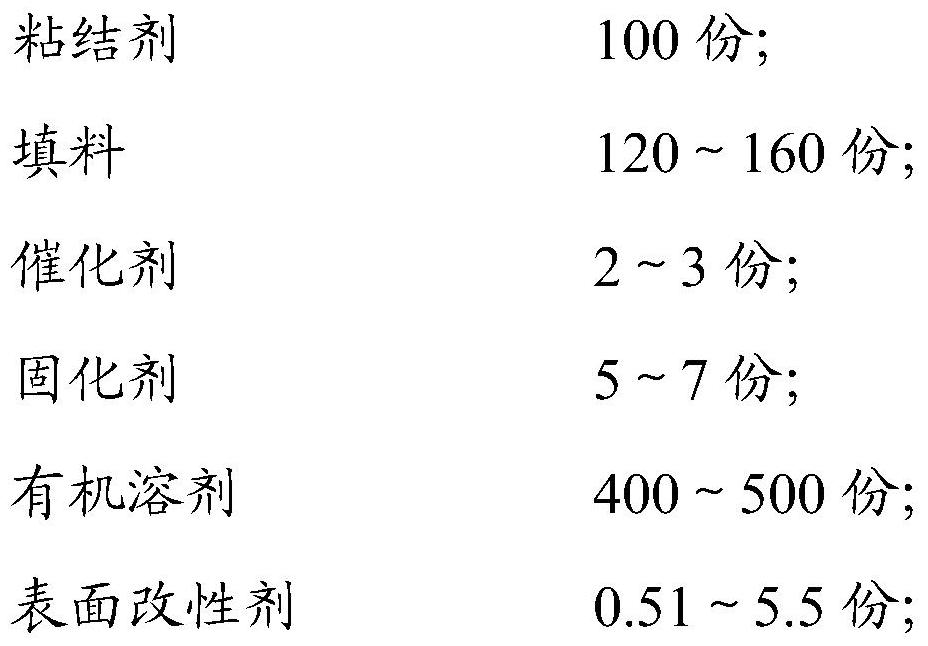

[0038] According to a second aspect of the present invention, there is provided a method for preparing a low-absorption and low-emission thermal control coating whose solar absorption ratio varies with the incident angle, comprising the following steps:

[0039] Weigh the filler, organic solvent and surfactant in proportion and mix them, then stir for 2-3 hours at 60-100°C;

[0040] Add the binder in proportion to the above mixing system, and then stir evenly at room temperature;

[0041] Add curing agent and catalyst in proportion to the above system, and stir evenly to form a coating paint that can be used for spraying;

[0042] The paint is directly coated on the surface of the product or part to be sprayed by air spraying, and the coating thickness is not less than 25 μm.

Embodiment 1

[0045] (1) Weigh 130g of flake metal aluminum powder and put it into a three-necked flask (particle size is about 35μm, thickness is not more than 2μm), then add 250g of mixed solvent of xylene and butyl acetate (mass ratio is 1:1), and then add Silane coupling agent KH550 2g, boric acid 0.02g; Stir for 3 hours at 80°C;

[0046] (2) Add 100 g of methylol silicone resin (molecular weight: 8,000 to 10,000) into the above system, and stir for 2 hours at room temperature;

[0047] (3) Add 5g ethyl orthosilicate and 2g dibutyltin dilaurate to the above system to obtain the paint material;

[0048] (4) Adopt the method of air spraying, spray on the surface of the parts, and the thickness of the coating after drying is 45-55 μm.

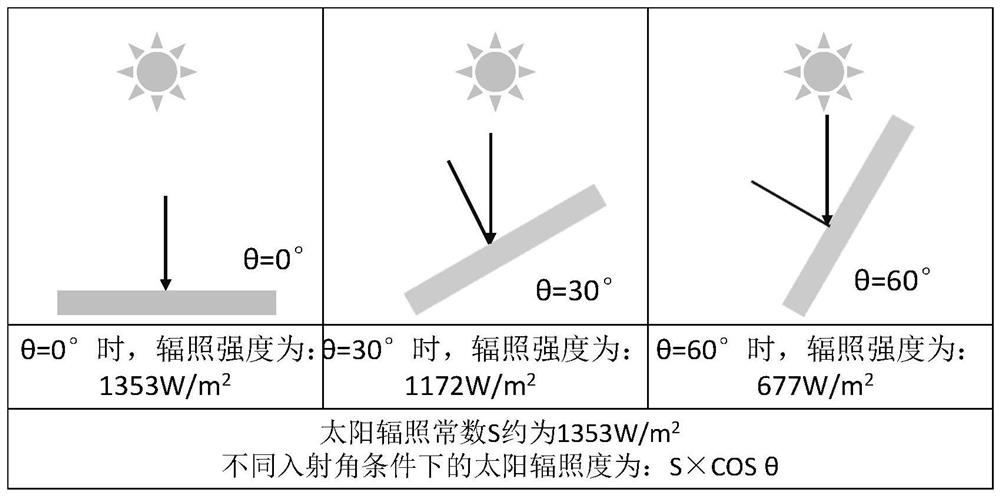

[0049] After testing, the hemispherical emissivity of the coating is 0.16, and the solar absorption ratio, solar radiation constant and thermal radiation absorption capacity per unit area under different incident angle conditions are as follows figure 2 ...

Embodiment 2

[0054] (1) Weigh 160g of flake metal aluminum powder and put it into a three-necked flask (particle size is about 45μm, thickness is not more than 2μm), then add 500g of mixed solvent of xylene and butyl acetate (mass ratio is 2:1), and then add KH550 silane coupling agent 3g, boric acid 0.1g; Stir at 100°C for 2 hours;

[0055] (2) Add 100 g of methylol silicone resin (molecular weight: 2000 to 5000) into the above system, and stir for 3 hours at room temperature;

[0056] (3) Add 4g ethyl orthosilicate and 3g dibutyltin dilaurate to above-mentioned system, obtain paint material;

[0057] (4) Adopt the method of air spraying, spray on the surface of the parts, and the thickness of the coating after drying is 35-47 μm.

[0058] After testing, the hemispherical emissivity of the coating is 0.15, and the solar absorption ratio, solar radiation constant and thermal radiation absorption capacity per unit area under different incident angles are shown in Table 2 below:

[0059] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com