PFA color master batch, preparation method thereof and PFA pre-coloring material

A color masterbatch and particle technology, applied in the field of PFA resin, can solve problems such as poor pigment dispersibility, and achieve the effects of high dispersibility, simple preparation method and friendly working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing PFA color masterbatch, comprising the following steps:

[0036] Add 5g of fluorine-containing green reactive dye to 20g of deionized water, add 100g of PFA emulsion to the dye solution under stirring, and its solid content is 45%. After agglomeration at 15°C for 10 minutes, green PFA particles are precipitated, and most of the water is filtered through a vibrating sieve, and the particles are dried at 150°C for 9 hours to obtain green PFA. The green PFA particles are added to the twin-screw extruder, The temperature of each section from zone 1 to zone 9 is as follows: 310°C, 310°C, 310°C, 315°C, 325°C, 335°C, 325°C, 325°C, 340°C, and the PFA green masterbatch is made by melt extrusion granulation .

[0037] A PFA pre-coloring material, the above-mentioned PFA green masterbatch and transparent PFA pellets are prepared by melting, blending, extruding and granulating through a twin-screw extruder at a weight ratio of 1:12 to obtain PFA green pellets...

Embodiment 2

[0039] A method for preparing PFA color masterbatch, comprising the following steps:

[0040] Add 10g of fluorine-containing black reactive dye to 20g of deionized water, add 100g of PFA emulsion to the dye solution under the condition of stirring, its solid content is 40%, after stirring and mixing evenly, add coagulant ammonia water, adjust the pH value to 9, After agglomeration at 15°C for 10 minutes, black PFA particles were precipitated, and most of the water was filtered through a vibrating sieve, and the particles were dried at 150°C for 9 hours to obtain black PFA, and the red PFA particles were added to the twin-screw extruder. The temperature of each section from the first zone to the ninth zone is: 310°C, 310°C, 310°C, 315°C, 325°C, 335°C, 325°C, 325°C, 340°C, and the PFA black masterbatch is made by melt extrusion granulation .

[0041] A PFA pre-coloring material, the above-mentioned PFA black masterbatch and transparent PFA pellets in a weight ratio of 1:20 are ...

Embodiment 3

[0043]A method for preparing PFA color masterbatch, comprising the following steps:

[0044] Add 12g of fluorine-containing red reactive dye to 20g of deionized water, add 100g of PFA emulsion to the dye solution under stirring, and its solid content is 35%. After agglomeration at 15°C for 10 minutes, red PFA particles were precipitated, and most of the water was filtered through a vibrating sieve, and the particles were dried at 150°C for 9 hours to obtain red PFA. The yellow PFA particles were added to the twin-screw extruder, The temperature of each section from zone 1 to zone 9 is as follows: 310°C, 310°C, 310°C, 315°C, 325°C, 335°C, 325°C, 325°C, 340°C, PFA red masterbatch is made by melt extrusion granulation .

[0045] A PFA pre-coloring material, the above-mentioned PFA red masterbatch and transparent PFA pellets are prepared in a weight ratio of 1:15 through a twin-screw extruder to produce PFA red pellets.

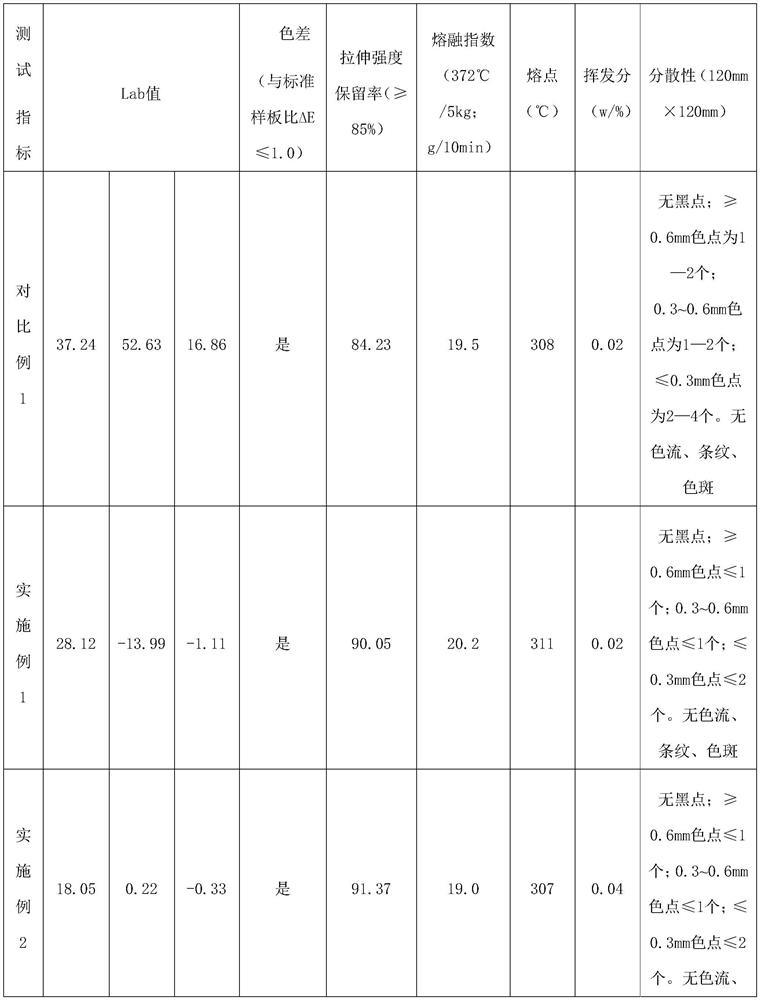

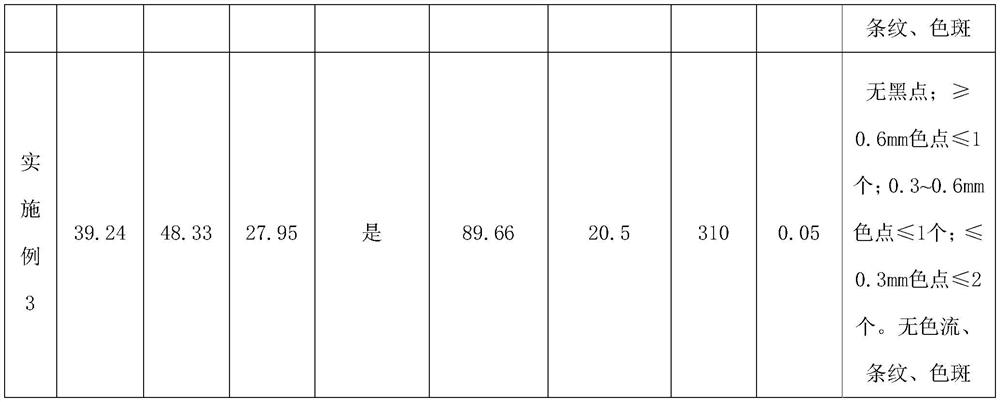

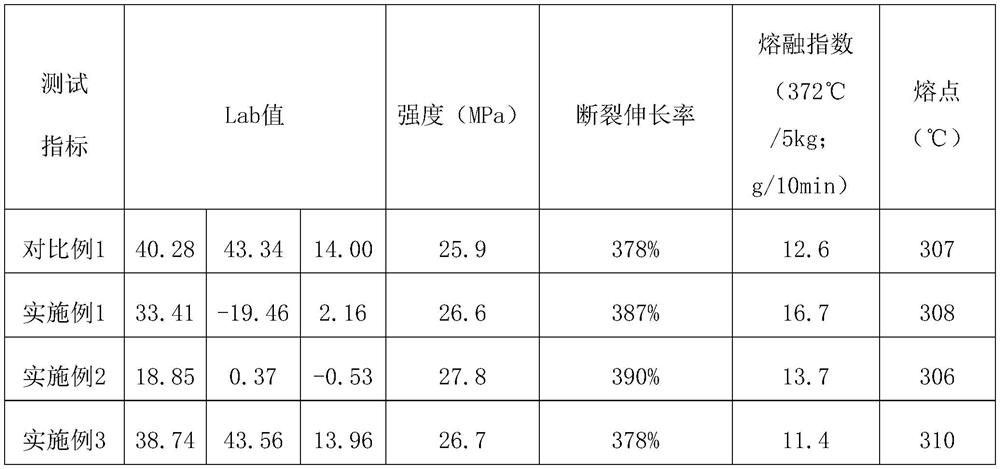

[0046] Performance Testing

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com