Self-repairing polysiloxane elastomer and preparation method thereof

A technology of polysiloxane and elastomer, which is applied in the field of self-repairing polysiloxane elastomer and its preparation, can solve the problems of shortening the service life of materials, poor tensile strength, tear strength, and degradation of material properties, and achieves The effect of improving stretchability and excellent stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

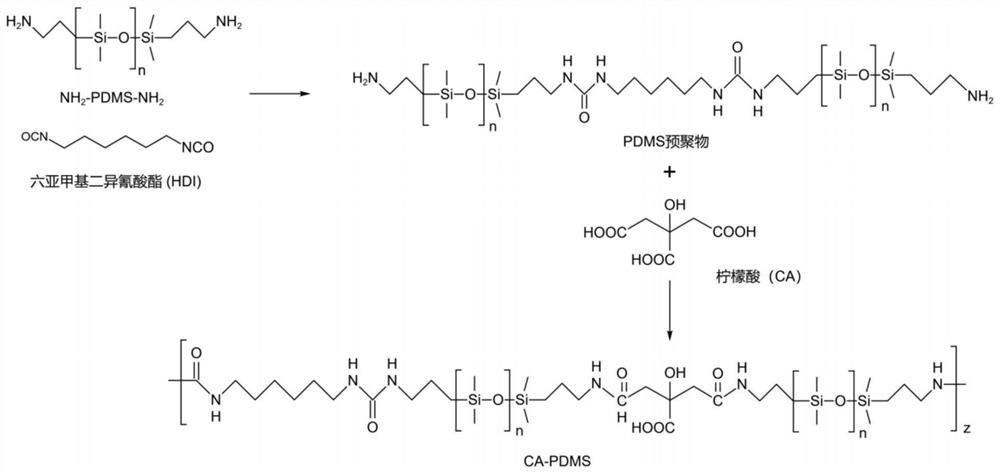

[0035] A method for preparing a self-healing polysiloxane elastomer with fluorescent properties, comprising the following preparation steps:

[0036] S1: Preparation of citric acid chloride: Dissolve 1 g of citric acid in 15 ml of tetrahydrofuran, stir and add 1.3 ml of thionyl chloride at 0°C, and react for 12 hours; Thionyl chloride, repeated 3 times to obtain light yellow transparent viscous citric acid chloride, add 10ml tetrahydrofuran and put it in the refrigerator for later use;

[0037] S2: Preparation of PDMS prepolymer: Dissolve 3g of aminopropyl-terminated polysiloxane in an appropriate amount of tetrahydrofuran, then add 0.1g of hexamethylene diisocyanate to it, mix well, and stir mechanically at room temperature for 24h at 25°C to obtain PDMS prepolymer;

[0038] S3: Preparation of polysiloxane elastomer (CA-PDMS): add 1.15ml of tetrahydrofuran solution of citric acid chloride prepared in step S2 to PDMS prepolymer, heat and reflux at 80°C in oil bath for 6h; pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com