Copper hydroxide film for oil-water separation and preparation method thereof

A copper hydroxide, oil-water separation technology, applied in separation methods, chemical instruments and methods, liquid separation and other directions, can solve the problems of long synthesis cycle, expensive preparation raw materials, environmental pollution, etc., and achieves low preparation method cost and high separation efficiency. Quantity and separation efficiency, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of the copper hydroxide membrane that is used for oil-water separation, comprises the following steps:

[0031] Will K 2 S 2 o 8 The aqueous solution and the NaOH solution are mixed until clarified to obtain a mixed solution A;

[0032] Immerse the copper grid in the mixed solution A, take it out and dry it to obtain the copper hydroxide film for oil-water separation.

[0033] In the present invention, the copper hydroxide film used for oil-water separation is preferably prepared by an in-situ growth method at room temperature.

[0034] In the present invention, the K 2 S 2 o 8 The concentration of the aqueous solution is 2.0×10 -4 ~3.0×10 -4 mol / L, preferably 2.5×10 -4 mol / L.

[0035] In the present invention, the concentration of the NaOH solution is 4.0×10 -3 ~6.0×10 -3 mol / L, preferably 5.0×10 -3 mol / L.

[0036] In the present invention, the K 2 S 2 o 8 The volume ratio of the aqueous solution to t...

Embodiment 1

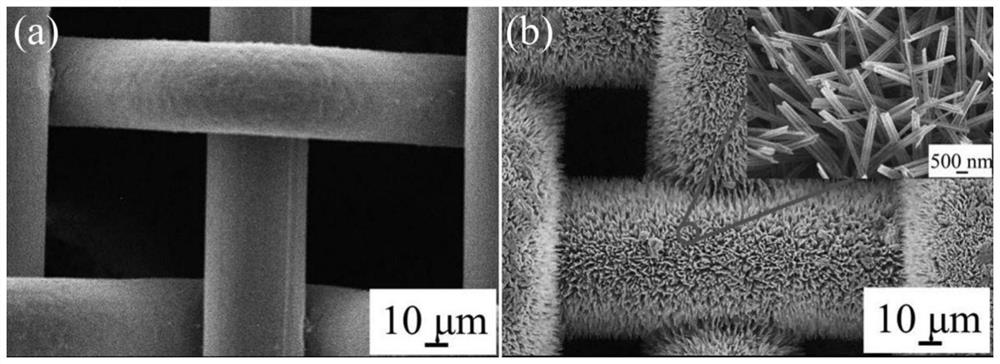

[0043] Cu(OH) 2 Membrane preparation:

[0044] 1) will K 2 S 2 o 8 Dissolved in distilled water to make a concentration of 2.5×10 -4 K in mol / L 2 S 2 o 8 Aqueous solution, dissolving NaOH in distilled water to make a concentration of 5.0×10 -3 mol / L NaOH solution; at room temperature, quickly add NaOH solution with a volume ratio of 1:1 to K 2 S 2 o 8 In the aqueous solution, stir rapidly until the solution is clear;

[0045] 2) Dip the 200-mesh red copper mesh into 1M hydrochloric acid, acetone and distilled water and ultrasonically clean it at 100W for 5 minutes, then dry it at room temperature;

[0046] 3) Immerse the cleaned copper mesh in the clear solution, take it out after 30 minutes, and dry it at room temperature to obtain Cu(OH) 2 membrane.

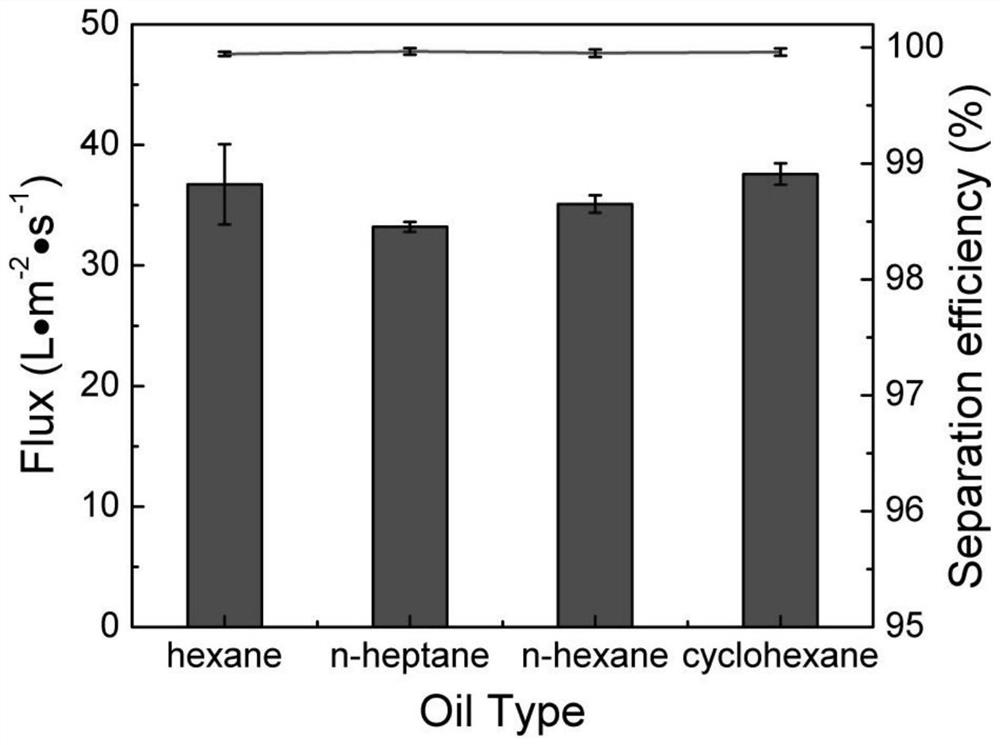

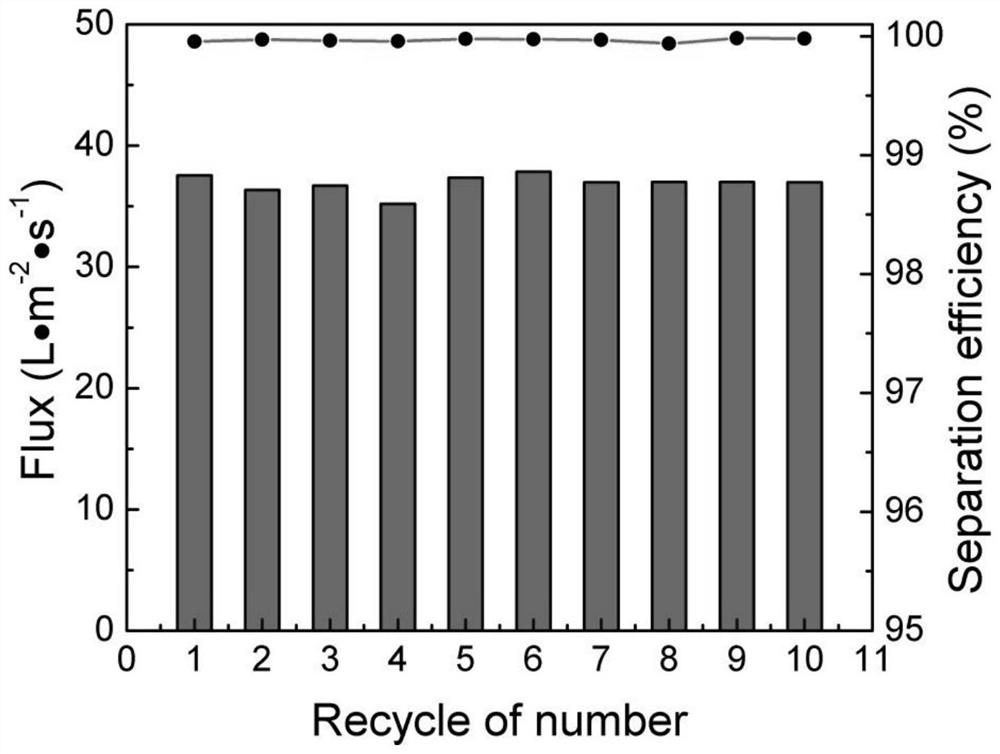

[0047] Cu(OH) 2 Membrane separation performance test for hexane / water mixed system:

[0048] 1) Mix 10 mL of hexane that has been colored by iodine and 20 mL of deionized water to make an oil-water mixture solution...

Embodiment 2

[0054] Cu(OH) 2 Membrane preparation:

[0055] 1) will K 2 S 2 o 8 Dissolved in distilled water to make a concentration of 2.5×10 -4 K in mol / L 2 S 2 o 8 Aqueous solution, dissolving NaOH in distilled water to make a concentration of 5.0×10 -3 mol / L NaOH solution; at room temperature, quickly add NaOH solution with a volume ratio of 1:1 to K 2 S 2 o 8 In the aqueous solution, stir rapidly until the solution is clear;

[0056] 2) Dip the copper mesh with a mesh number of 200 into 2M hydrochloric acid, acetone and distilled water, ultrasonically clean it at 100W for 8 minutes, and then dry it at room temperature;

[0057] 3) Immerse the cleaned copper mesh in the clear solution, take it out after 20 minutes, and dry it at room temperature to obtain Cu(OH) 2 membrane.

[0058] Cu(OH) 2 Membrane separation performance test for n-heptane / water mixed system:

[0059] 1) Mix 10mL of n-heptane and 20mL of deionized water to make a mixed solution of oil and water.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com