Carbon nanotube thermal interface material as well as preparation method and application thereof

A technology of thermal interface materials and carbon nanotubes, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of unreachable applications, increased surface thermal resistance, and inability to consider packaging issues, etc., to achieve high Thermal conductivity, meet the heat dissipation needs, and realize the effect of lossless transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

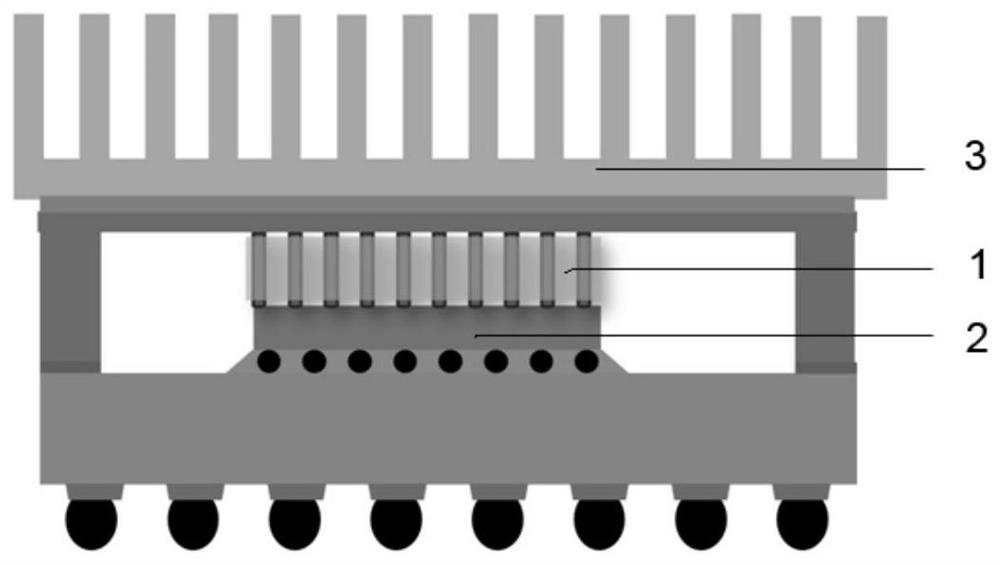

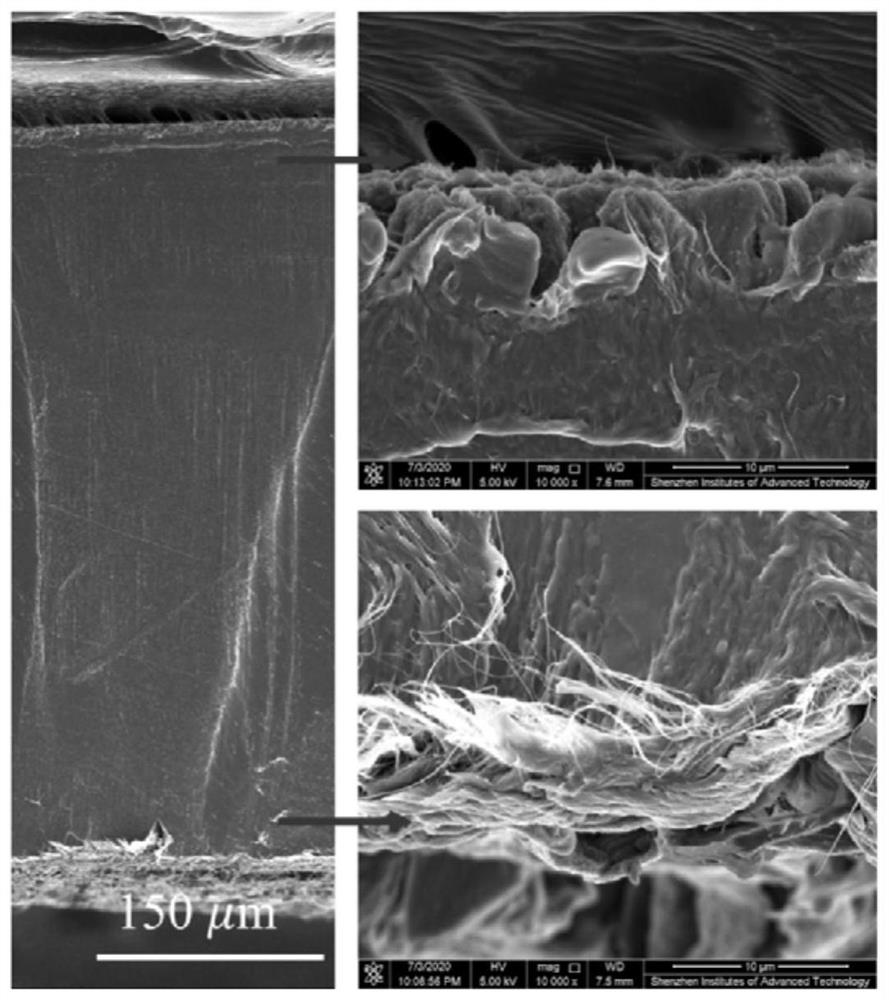

[0065] Example 1 Preparation of Vertically Aligned Carbon Nanotube Thermal Interface Material

[0066] (1) spin-coating UV-curable glue on a polyethylene terephthalate substrate;

[0067] (2) For the carbon nanotube array grown on the silicon substrate, paste the UV-curable glue that has been spin-coated in the previous step on its free end; then irradiate with ultraviolet light to cure the UV-curable glue;

[0068] (3) transferring the carbon nanotube array so that the end face of the growth sheet where the carbon nanotube array is in contact with the growth sheet is exposed;

[0069] (4) Paste the same UV-curable glue on the end face of the carbon nanotube array growth sheet, so as to obtain the carbon nanotube array whose upper and lower surfaces are all protected by the UV-curable glue;

[0070] (5) epoxy resin with mechanical buffering properties is filled between the carbon nanotube arrays;

[0071] (6) Removing the UV-curable glue to obtain a heat dissipation interfac...

Embodiment 2

[0074] Example 2 Preparation of Vertically Aligned Carbon Nanotube Thermal Interface Material

[0075] (1) scrape photoresist on polyimide substrate;

[0076] (2) For the carbon nanotube array grown on the copper substrate, affix the UV-curable glue that has been scraped in the previous step on its free end; then irradiate with ultraviolet light to cure the UV-curable glue;

[0077] (3) transferring the carbon nanotube array so that the end face of the growth sheet where the carbon nanotube array is in contact with the growth sheet is exposed;

[0078] (4) Paste the same photoresist as above on the end face of the carbon nanotube array growth sheet, so as to obtain the carbon nanotube array whose upper and lower surfaces are all protected by the photoresist;

[0079] (5) Silica gel with mechanical buffering properties is filled between the carbon nanotube arrays;

[0080] (6) The photoresist is removed to obtain a heat dissipation interface material with a designable surface...

Embodiment 3

[0082] Example 3 Preparation of Vertically Aligned Carbon Nanotube Thermal Interface Material

[0083] (1) Spin-coat temporary bonding glue on the polytetrafluoroethylene substrate;

[0084] (2) Aiming at the carbon nanotube array grown on the silicon dioxide substrate, affix the temporary bonding glue that has been scraped in the previous step on its free end; heat and dry to obtain the cured temporary bonding glue;

[0085] (3) transferring the carbon nanotube array so that the end face of the growth sheet where the carbon nanotube array is in contact with the growth sheet is exposed;

[0086] (4) Paste the same temporary bonding glue as above on the end face of the carbon nanotube array growth sheet, so as to obtain the carbon nanotube array whose upper and lower surfaces are all protected by the temporary bonding glue;

[0087] (5) Filling polyimide resin with mechanical buffering properties between the carbon nanotube arrays;

[0088] (6) The temporary bonding glue is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com