Method for detecting tribromoneopentyl alcohol and 2, 3-dibromopropanol

A technology of tribromoneopentyl alcohol and dibromopropanol, which is applied in the field of detection of tribromoneopentyl alcohol and 2,3-dibromopropanol, and achieves the effects of simple operation, high selectivity and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

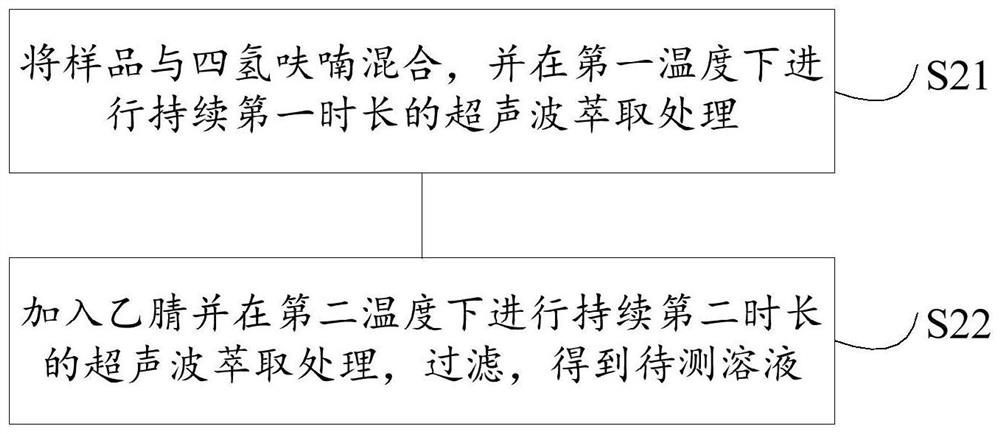

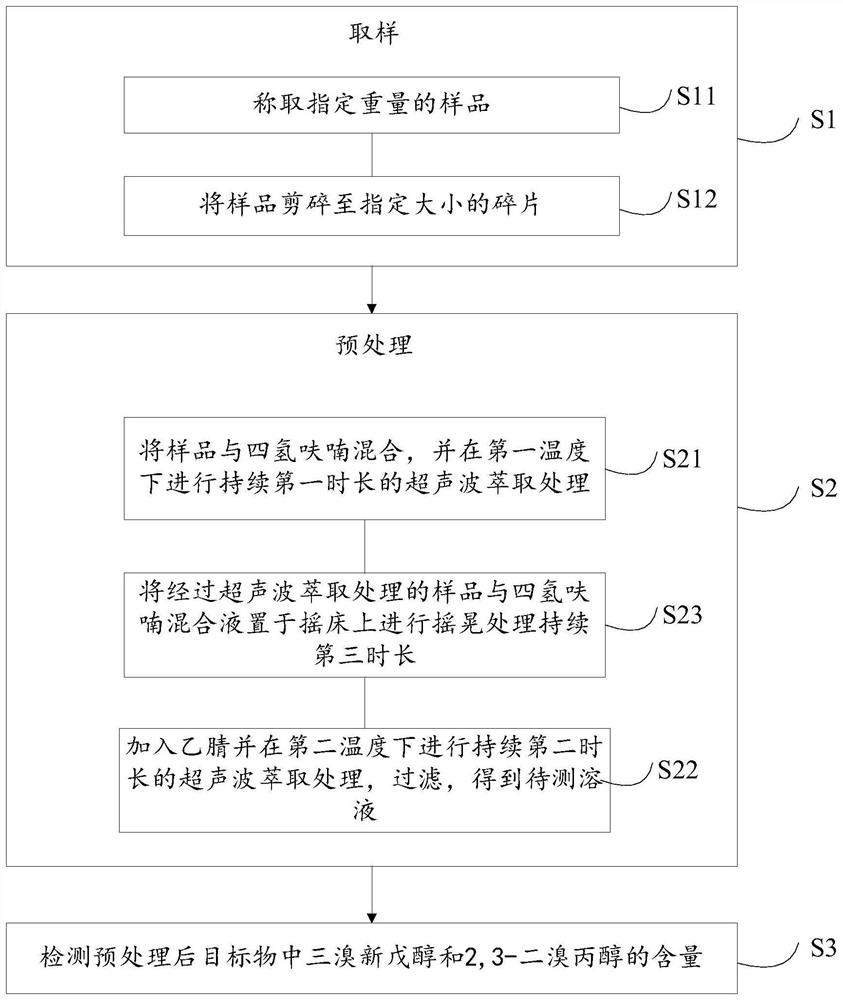

Method used

Image

Examples

Embodiment 1

[0079] In specific embodiment 1, the method for detecting tribromoneopentyl alcohol and 2,3-dibromopropanol comprises:

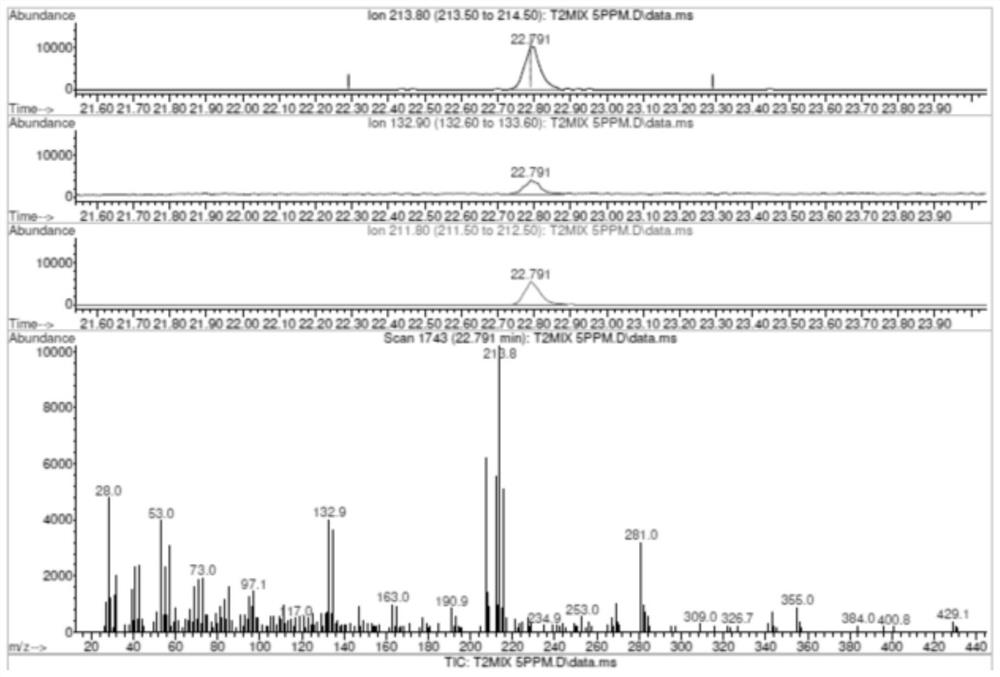

[0080] Weigh 1.05g of the plastic sample to be tested, cut the plastic sample to be tested into 5mm×5mm sample fragments, put them in a test tube, add 10mL tetrahydrofuran to mix, and conduct ultrasonic extraction on the mixture at 70°C for 30min ; then placed on a shaker and shaken for 35 minutes; then added 20 mL of acetonitrile to the solution, and then carried out ultrasonic extraction at a temperature of 70 ° C for 30 minutes, and then filtered to obtain the solution to be tested and waited for detection on the machine, using gas chromatography-mass spectrometry The chromatographic conditions used are: chromatographic column: DB-624, inlet temperature: 250°C; injection volume: 1μL; split mode: pulse without split; heating curve: initial temperature 40°C, 5°C / min Raise the temperature to 80°C, raise the temperature to 120°C at 10°C / min, then raise the te...

specific Embodiment 2

[0082] In specific embodiment 2, the method for detecting tribromoneopentyl alcohol and 2,3-dibromopropanol comprises:

[0083] Weigh 0.95g of the thermoplastic sample to be tested, cut the plastic sample to be tested into 5mm×5mm sample fragments, put them in a test tube, add 10mL tetrahydrofuran for mixing, and conduct ultrasonic extraction on the mixture at a temperature of 70°C 30min; then placed on a shaker and shaken for 30min; then added 20mL of acetonitrile to the solution, and then carried out ultrasonic extraction treatment at a temperature of 70°C for 30min, and then filtered to obtain the solution to be tested on the machine, using gas chromatography-mass spectrometry The instrument was used for detection, and the chromatographic conditions used were: chromatographic column: DB-624, inlet temperature: 250°C; injection volume: 1μL; split mode: pulse without split; Raise the temperature to 80°C in min, then raise the temperature to 120°C at 10°C / min, then raise the t...

specific Embodiment 3

[0085] In specific embodiment 3, the method for detecting tribromoneopentyl alcohol and 2,3-dibromopropanol comprises:

[0086]Weigh 1.00g of the textile fabric sample to be tested, cut the textile fabric sample to be tested into 5mm×5mm sample fragments, put them in a test tube, add 10mL tetrahydrofuran for mixing, and conduct ultrasonic waves on the mixture at a temperature of 70°C Extract for 30 minutes; then shake on a shaker for 25 minutes; then add 20 mL of acetonitrile to the solution, perform ultrasonic extraction at a temperature of 70 ° C for 30 minutes, and then filter to obtain the test solution to be tested on the machine, using gas chromatography mass spectrometry The chromatographic conditions used for detection are: chromatographic column: DB-624, inlet temperature: 250°C; sample volume: 1μL; split mode: pulse without split; heating curve: initial temperature 40°C, increasing to 5°C / min to 80°C, 10°C / min to 120°C, then 15°C / min to 250°C, and hold for 5 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com