Method and device for co-producing polysaccharide through high-density semi-continuous culture of porphyridium

A Porphyridium, semi-continuous technology, applied in the field of marine microorganisms, can solve the problems of undetermined biochemical variation, singleness, lack, etc., and achieve the effect suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

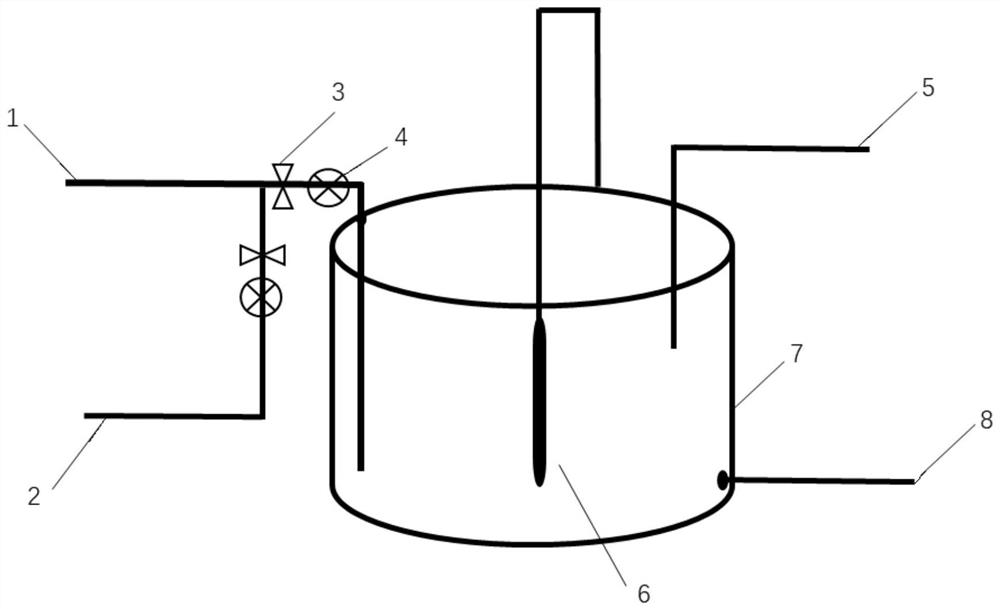

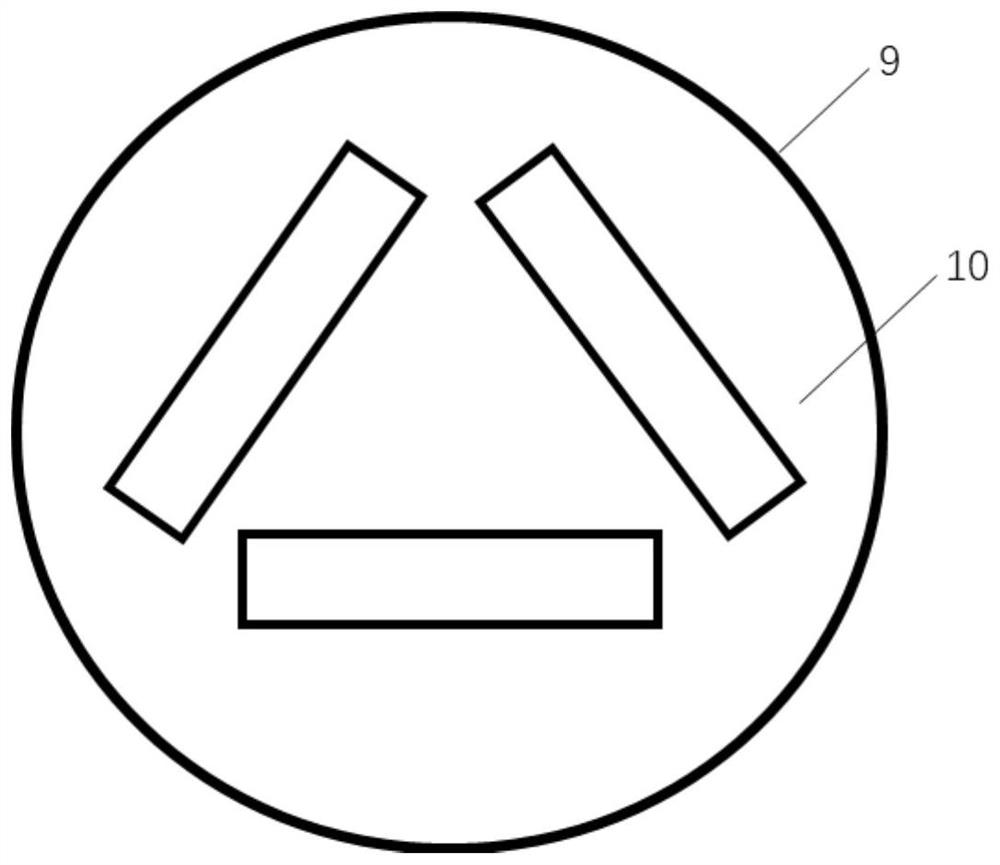

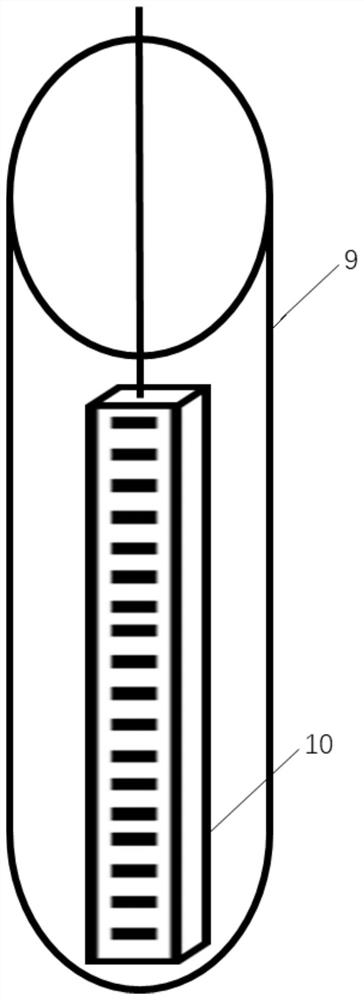

[0033] Pre-cultivate the Porphyridum seed liquid in OMII medium first, inoculate the normal cultured to the end of the logarithmic phase of the Porphyridum seed liquid into the OMⅡ medium in the bioreactor to expand the culture, and control the initial Porphyridum cell inoculation amount 6×10 5 a / L. Culture conditions: culture temperature is 25°C and pH 6.5 is monitored and adjusted in time by the thermometer and pH meter installed on the top of the bioreactor, the light source is illuminated by LED cool white light, and the light intensity is adjusted to 80μE.m -2 .s -1 1% carbon dioxide is introduced through the ventilation pipe extending to the bottom of the bioreactor, and the ventilation rate is 10L / min. After 7 days of cultivation under the above-mentioned cultivation conditions, the semi-continuous cultivation begins when Porphyridium enters the logarithmic phase, and the cultivation is carried out according to OMⅡ NaNO 3 The concentration of each feed was 0.5g / L for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com