Tightening treatment method for micro-nano metal paste filling hole and micro-hole filling process

A treatment method, micro-nano metal technology, applied in the direction of nanotechnology, nanotechnology, electric solid devices, etc., to achieve the effect of increasing density, increasing solid content, and improving electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

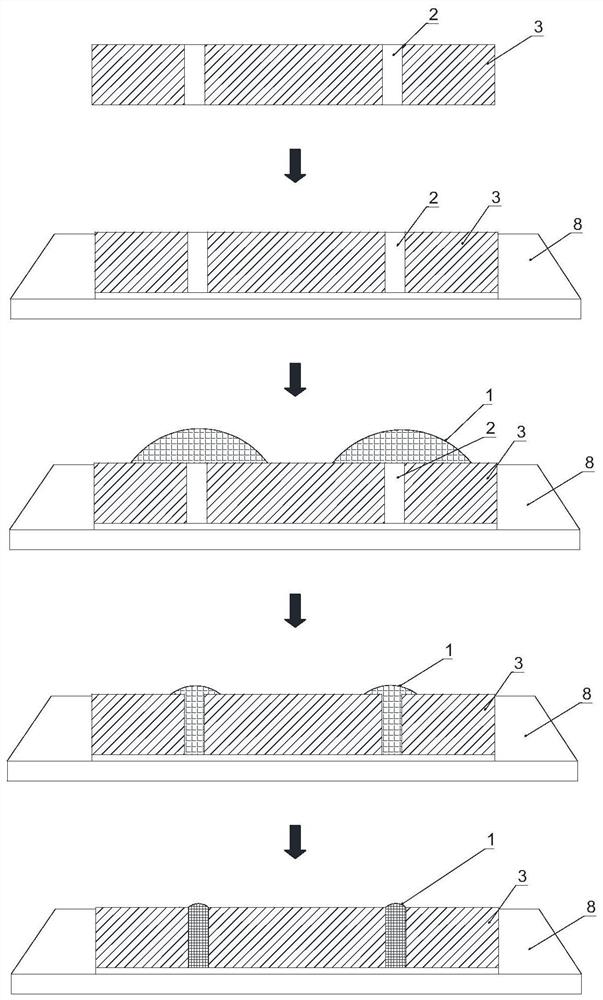

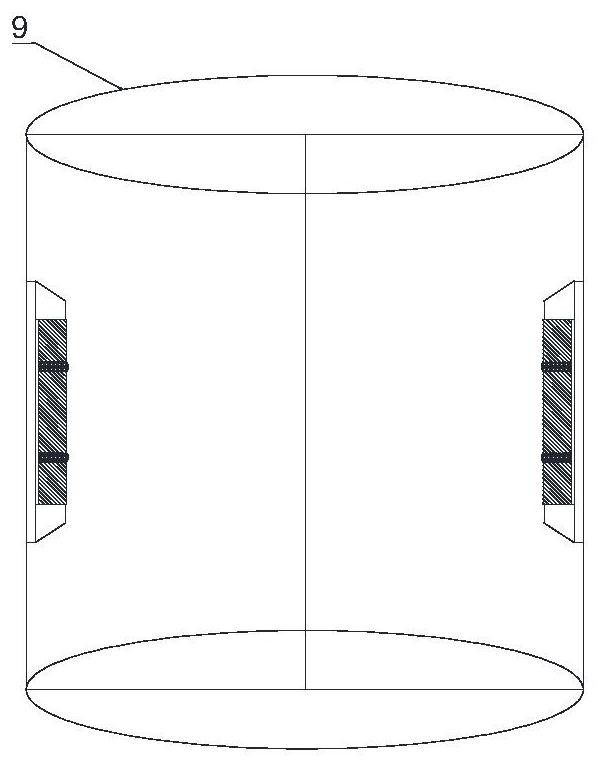

[0048] see Figure 1-Figure 2 , the present embodiment discloses a compaction processing method for filling holes with micro-nano metal paste, comprising the following steps:

[0049](1) Fix the sample substrate 3 on the substrate fixture 8; first coat and fill the micro-nano metal paste 1 on the surface of the to-be-filled hole 2 of the sample substrate 3, and then carry out the Vacuum treatment makes the micro-nano metal paste 1 quickly flow into the to-be-filled hole 2 under the conditions of its own tension and pressure difference. Of course, the holes 2 to be filled on the sample substrate 3 can also be evacuated first, so that the gas in the holes 2 to be filled overflows, and then the micro-nano metal paste 1 is coated and filled on the surface of the holes 2 to be filled, so as to The infiltration of the micro-nano metal paste 1 is realized.

[0050] (2) The micro-nano metal paste 1 in the sample substrate 3 or the to-be-filled hole 2 is acted upon by an external ins...

Embodiment 2

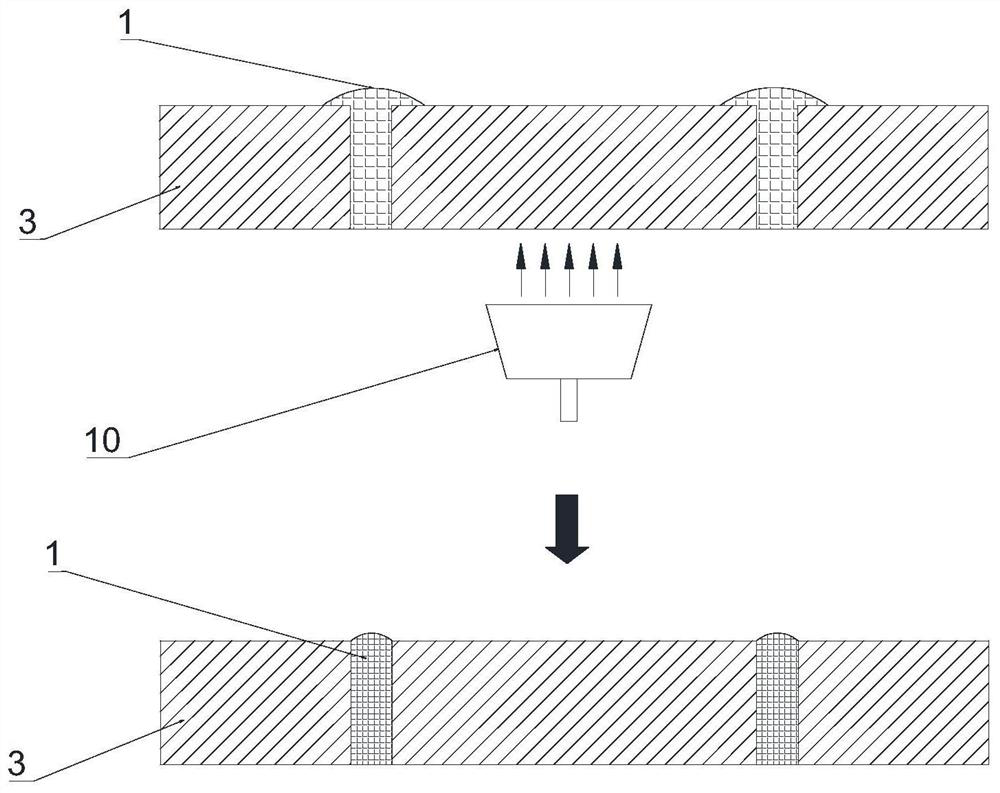

[0053] see figure 1 and image 3 The difference between this embodiment and Embodiment 1 is that in step (2), the impact load is generated on the sample substrate 3 by the impact device 10, so that the micro-nano metal paste 1 has the ability to move to the bottom of the hole 2 to be filled. Therefore, the micro-nano metal paste 1 and the to-be-filled hole 2 move relative to each other, thereby realizing the compaction of the micro-nano metal paste 1 . In addition, the rigidity of the material of the sample substrate 3 cannot be too large to ensure that the substrate will not be damaged after being impacted.

[0054] see image 3 , and further, the sample substrate 3 is placed horizontally, and the impact device 10 generates an upward impact load on the sample substrate 3 from bottom to top, so that the micro-nano metal paste 1 has an acceleration to move to the bottom (downward) of the hole 2 to be filled, thereby Move to the bottom of the hole to be filled 2 to realize th...

Embodiment 3

[0056] The difference between this embodiment and Embodiment 2 is that the impact device 10 generates a downward impact load on the sample substrate 3 from top to bottom, and then pushes the micro-nano metal paste 1 to move to the bottom of the hole to be filled 2 through an emergency stop. The acceleration (the inertial force of downward movement), so as to move to the bottom of the hole to be filled 2 to realize the compaction of the micro-nano metal paste 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com