Method for preparing super absorbent resin from sorghum straws

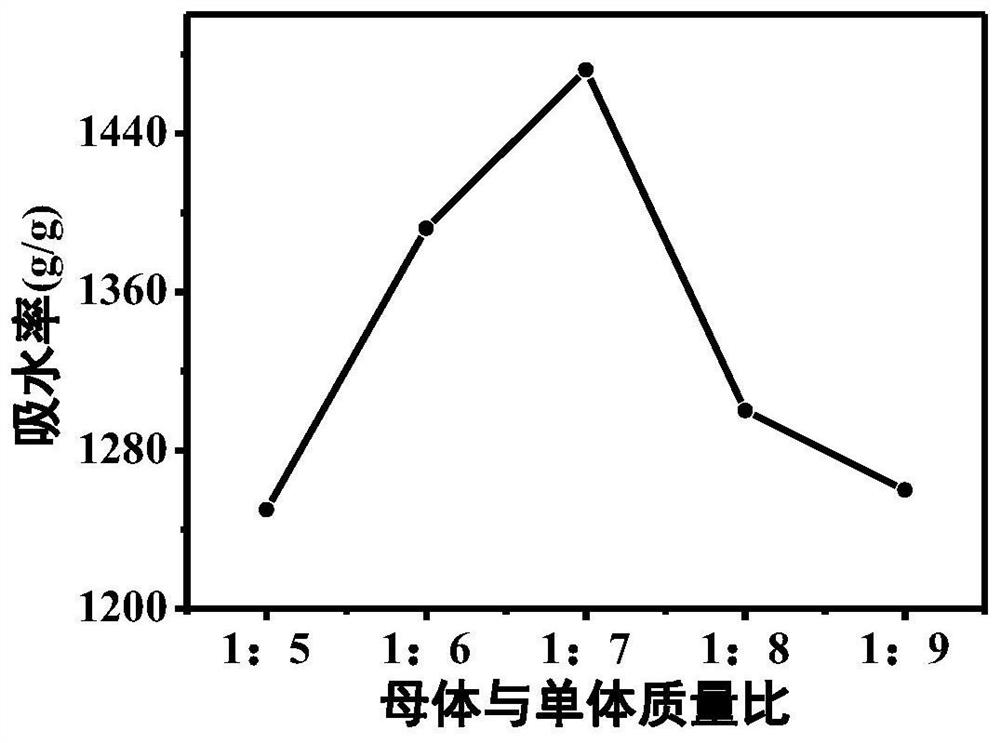

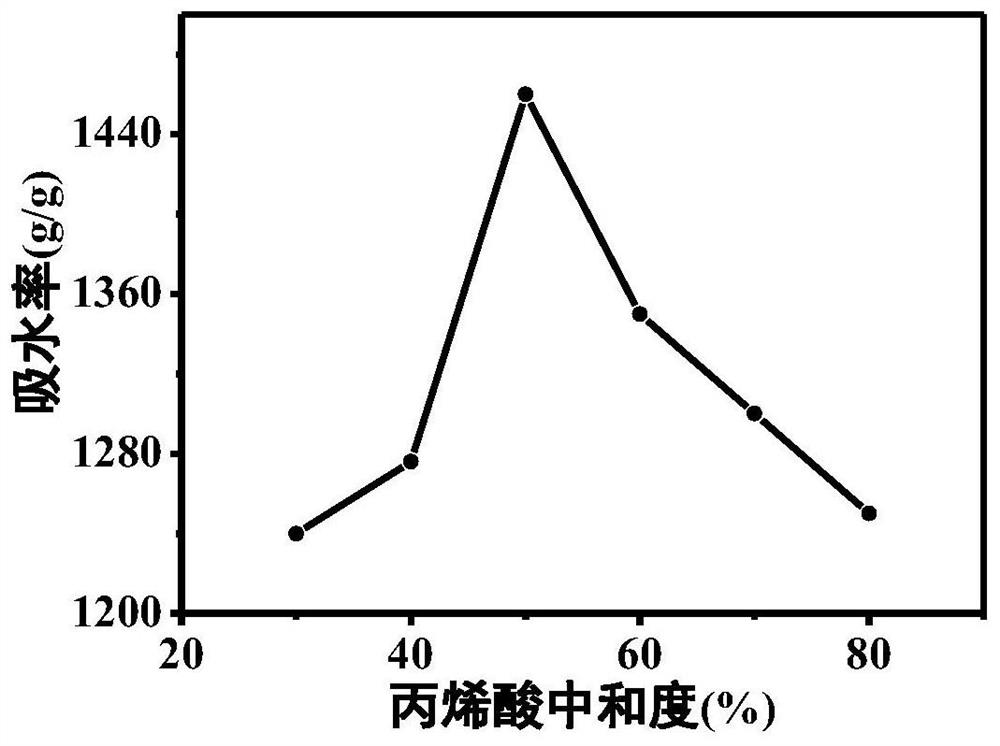

A technology of superabsorbent resin and sorghum straw, which is applied in the field of preparation of superabsorbent resin from sorghum straw, which can solve the problems of high reaction temperature and low water absorption rate, and achieve the effects of simple synthesis process, large market competitiveness and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Weigh 10.0g of sodium hydroxide, measure 400mL of deionized water, prepare 2.5% sodium hydroxide solution, weigh 50.0g of sorghum straw powder that has passed through a 100 mesh sieve, and mix the sorghum straw powder with 2.5% hydroxide under stirring The sodium solution was mixed evenly in a three-necked bottle, and soaked for 12 hours. Then weigh 50.0g sodium hydroxide, measure 150mL deionized water, prepare a 33.3% sodium hydroxide solution, add two-thirds of the 33.3% sodium hydroxide solution dropwise to the above-mentioned three-necked bottle after soaking, at 30°C Heat in a water bath for alkalization for 1.5 hours. Weigh 34.8g sodium chloroacetate, measure 100mL deionized water, prepare sodium chloroacetate solution, add dropwise to the solution after alkalization reaction, adjust the temperature of the water bath to 75°C, and pour the solution into In a stainless steel pan, heat in an oven at 70°C for 2 hours, dry, pulverize, and wash to obtain carboxymethyl ...

Embodiment 2

[0079] Weigh 12.0g of sodium hydroxide, measure 400mL of deionized water, prepare 3% sodium hydroxide solution, weigh 50.0 g of sorghum straw powder that has passed through a 100 mesh sieve, and mix the sorghum straw powder with 3% hydroxide under stirring The sodium solution was mixed evenly in a three-necked bottle, and soaked for 12 hours. Then weigh 50.0g sodium hydroxide, measure 150mL deionized water, prepare a 33.3% sodium hydroxide solution, add two-thirds of the 33.3% sodium hydroxide solution dropwise to the above-mentioned three-necked bottle after soaking, at 30°C Heat in a water bath for alkalization for 1.5 hours. Weigh 36.5g sodium chloroacetate, measure 100mL deionized water, prepare sodium chloroacetate solution, add dropwise to the solution after alkalization reaction, adjust the temperature of the water bath to 75°C, and pour the solution into In a stainless steel pan, heat in an oven at 70°C for 2 hours, dry, pulverize, and wash to obtain carboxymethyl sor...

Embodiment 3

[0082] Weigh 14.0g of sodium hydroxide, measure 400mL of deionized water, prepare 3.5% sodium hydroxide solution, weigh 50.0g of sorghum straw powder that has passed through a 100 mesh sieve, and mix the sorghum straw powder with 3.5% hydroxide The sodium solution was mixed evenly in a three-necked bottle, and soaked for 12 hours. Then weigh 50.0g sodium hydroxide, measure 150mL deionized water, prepare a 33.3% sodium hydroxide solution, add two-thirds of the 33.3% sodium hydroxide solution dropwise to the above-mentioned three-necked bottle after soaking, at 30°C Heat in a water bath for alkalization for 1.5 hours. Weigh 42.6g sodium chloroacetate, measure 100mL deionized water, prepare sodium chloroacetate solution, add dropwise to the solution after alkalization reaction, adjust the temperature of water bath to 35°C, and pour the solution into In a stainless steel pan, heat in an oven at 70°C for 2 hours, dry, pulverize, and wash to obtain carboxymethyl sorghum cellulose w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com