Novel multi-wire cutting mechanism with variable axial spacing

A multi-wire cutting machine and multi-wire cutting technology, which is applied in the direction of grinding frame, grinding machine parts, working accessories, etc., can solve the problems of poor cutting surface quality, reduced cutting efficiency, and large warpage of cut sheets. , to achieve the effect of convenient operation of the mechanism, reduction of cutting efficiency, and high rigidity of the wire mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

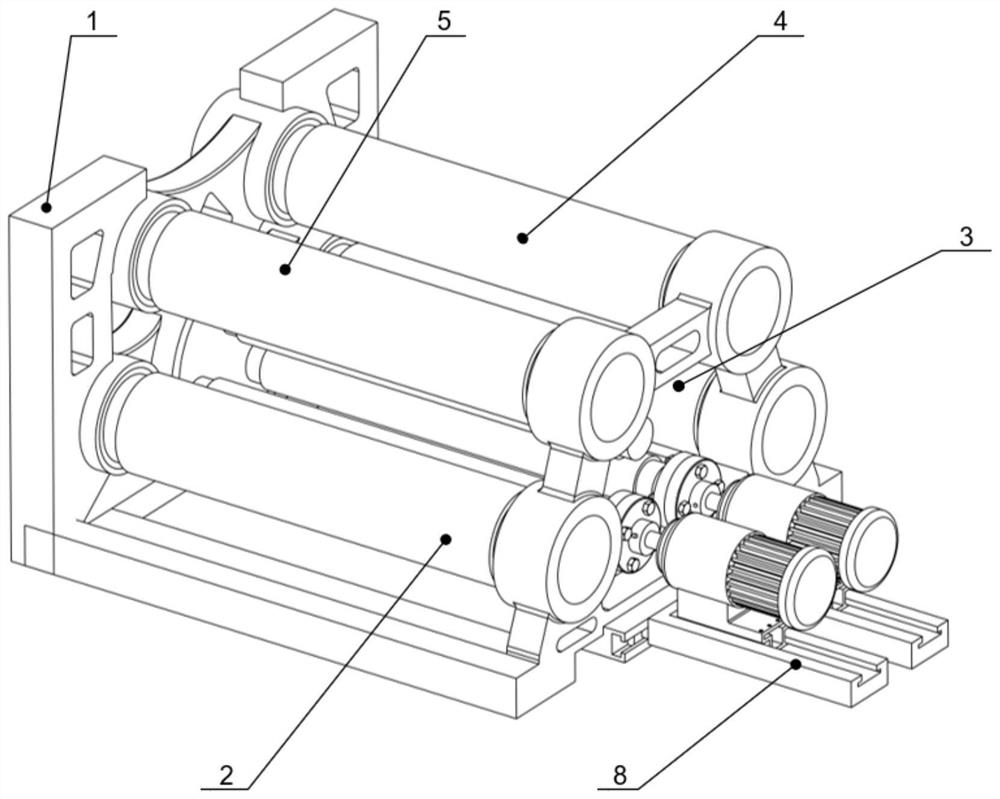

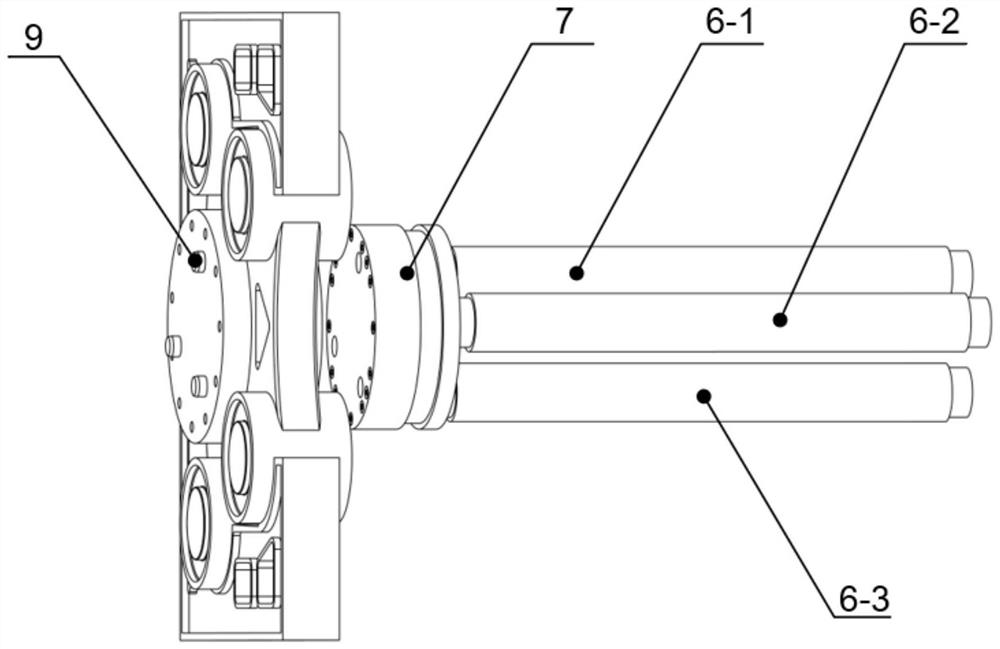

[0052] The invention provides a new multi-wire cutting mechanism with variable axis spacing, which can be applied to a multi-wire roller multi-wire cutting machine. The mechanism includes: frame 1, line roll one 2, line roll two 3, line roll three 4, line roll four 5, line roll five 6-1, line roll six 6-2, line roll seven 6-3, rotor 7. Guide rail 8 and positioning pin 9.

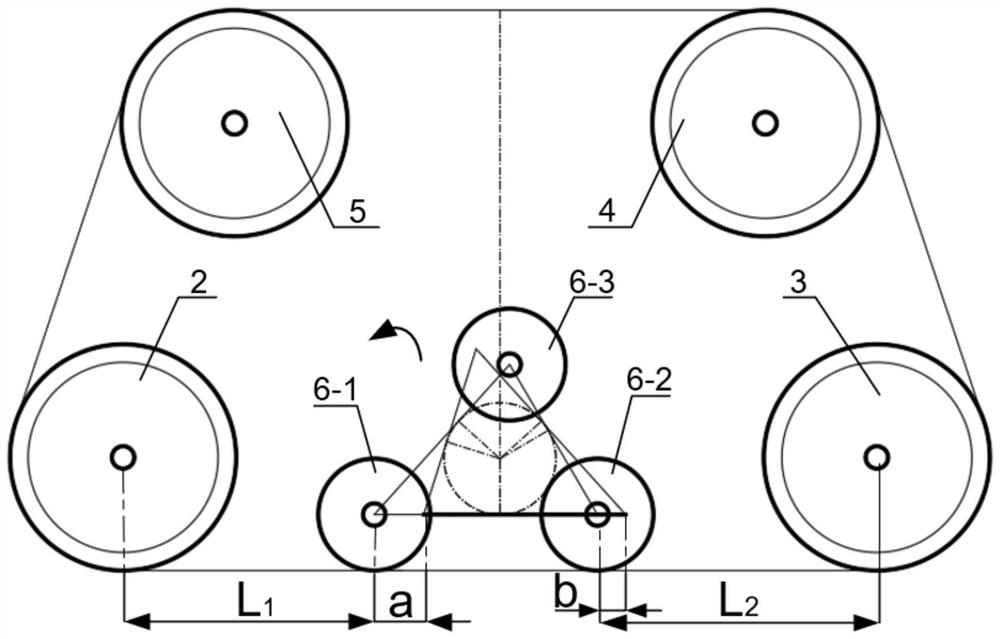

[0053]In this mechanism, wire roller 1, wire roller 3, wire roller 3, wire roller 4, and wire roller 5 have the same specifications and sizes, and are respectively installed on the four front and rear coaxial inner holes of the frame, wire roller 5 6-1, wire roller 6 6-2, Line Roller 7 6-3 The specifications and sizes are exactly the same. According to the three vertices of the triangle inscribed circle as the center of the circle, the rotor 7 is fixed and installed. The rotor is positioned and installed on the inner hole of the frame 1 by three positioning pins 9. According to The geometric characteristics...

Embodiment 2

[0058] A new multi-wire cutting mechanism with variable axis spacing adjusts the center spacing of wire nets in two cutting areas to realize simultaneous cutting of two different workpieces. The mechanism is located in the cutting room of the multi-wire cutting machine, such as figure 1 , figure 2 , including frame 1, line roll one 2, line roll two 3, line roll three 4, line roll four 5, line roll five 6-1, line roll six 6-2, line roll seven 6-3, rotor 7, Guide rail 8, positioning pin 9.

[0059] Wire roll one 2, wire roll two 3, wire roll three 4, and wire roll four 5 are fixedly installed in the four inner holes of the frame, and these four wire rolls are independently driven by four servo motors. Line roll five 6-1, line roll six 6-2, line roll seven 6-3 are fixedly installed with rotor 7, and rotor 7 is installed in the frame inner hole. Cutting wire mesh consists of wire roll one 2, wire roll two 3, wire roll three 4, wire roll four 5 and selected wire roll five 6-1, ...

Embodiment 3

[0063] Such as Figure 5 As shown, different from Embodiment 2, in this embodiment, the circumscribed triangle of the large and small circles on the rotor 7 adopts an isosceles triangle, and the distance between the centers of the wire roller 5 6-1 and the wire roller 6 6-2 is the base e, Line roller five 6-1 and line roller seven 6-3 and line roller six 6-2 and line roller seven 6-3 center distances are all waist f.

[0064] When selecting line roll five 6-1 and line roll six 6-2 as the working line rolls in the present embodiment, the wire mesh is composed of line roll one 2, line roll two 3, line roll three 4, line roll four 5 and line roll five 6-1, wire roller six 6-2 winding work, the wire under the wire net is evenly divided into two cutting areas with the same spacing by wire roller five 6-1 and wire roller six 6-2, wire roller one 2 and wire roller Five 6-1 center horizontal spacing is L 3 , the horizontal distance between the centers of line roll two 3 and line rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com