Evaluation method for rigidity of longitudinal horizontal line of arch pier top of steel truss arch bridge for deck-arch railway

A steel truss arch bridge, horizontal line technology, applied in geometric CAD, design optimization/simulation, special data processing applications, etc., to achieve the effect of real and reliable calculation, reasonable analysis and calculation, and cost avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

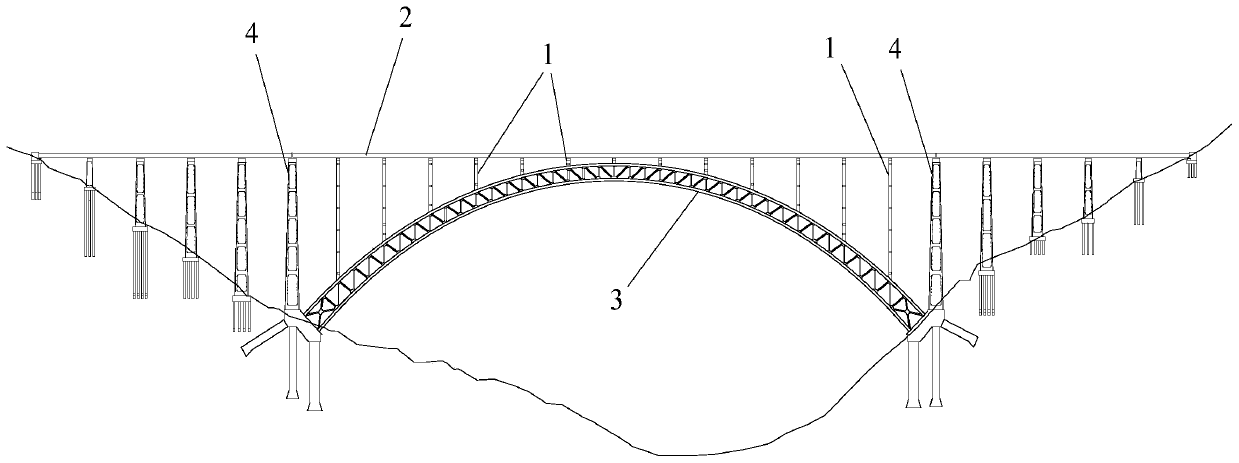

[0024] For example, take the above-supported railway steel truss arch bridge with a main span of 490m as an example, such as figure 1 As shown, the steel truss arch circle 3 has a rise height of 109.5m and a rise-span ratio of 1 / 4.475. Its cross-section adopts four trusses, and a total of 13 arch piers 1 are arranged symmetrically. The arch piers 1 are portal-type steel piers. The beam 2 is a steel box girder, and the junction pier 4 is a portal-type rigid frame pier structure. The span of the arched beam 2 is 14×37.2m. The railway includes four lines, which are two main lines and two arrival and departure lines.

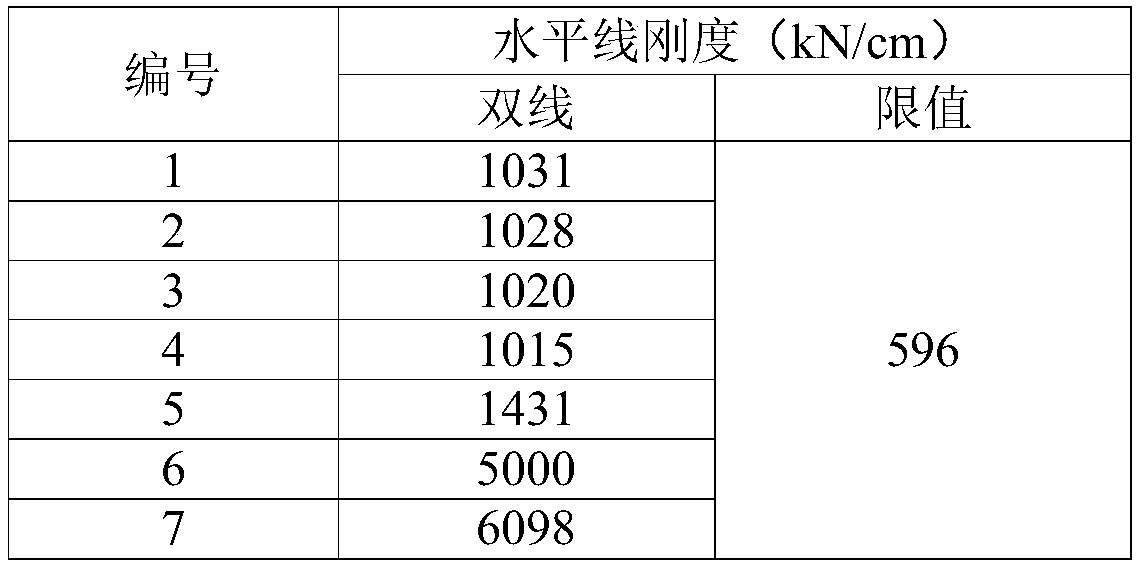

[0025] According to the design requirements of the current "Code for Design of Railway Bridges and Culverts", the rigidity limits of the vertical horizontal line of the pier top of conventional bridges (simply supported girders, continuous girders, continuous steel structures, and tied arch bridges, etc.) are shown in Table 1. The limit value of the minimum horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com