High-uniformity and high-power laser epitaxial wafer and preparation method thereof

A technology of lasers and epitaxial wafers, applied in the field of optoelectronics, can solve the problems of great influence of temperature, poor wavelength uniformity of epitaxial wafers, carrier leakage, etc., and achieve the effect of improving growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

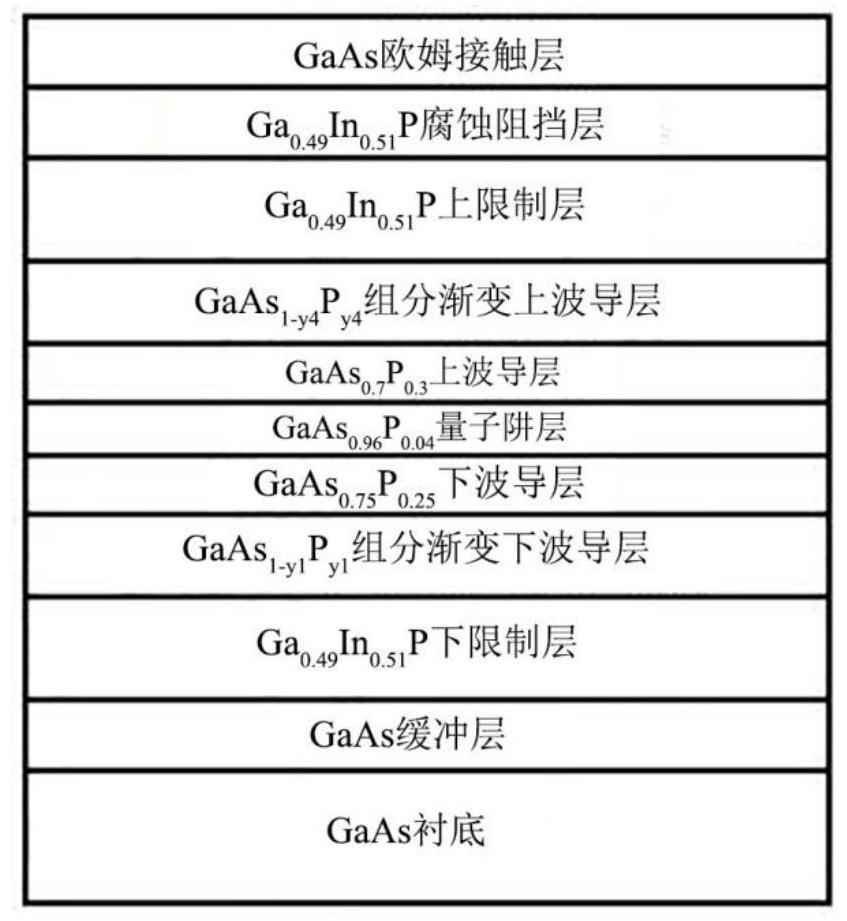

[0051] A high-uniformity high-power laser epitaxial wafer, using a GaAs substrate, on the GaAs substrate from bottom to top includes: GaAs buffer layer, GaAs 0.49 In 0.51 P lower confinement layer, GaAs 1-y1 P y1 Compositionally graded lower waveguide layer, GaAs0.75 P 0.25 Lower waveguide layer, GaAs 0.96 P 0.04 Quantum well layer, GaAs 0.7 P 0.3 Upper waveguide layer, GaAs 1-y4 P y4 Composition-graded upper waveguide layer, Ga 0.49 In 0.51 Confinement layer on P, Ga 0.49 In 0.51 P corrosion barrier layer, GaAs ohmic contact layer; its structure is as figure 1 shown.

[0052] In this example, GaAs 0.75 P 0.25 Lower waveguide layer and GaAs 0.7 P 0.3 The thickness of the upper waveguide layer is 15nm;

[0053] GaAs 1-y1 P y1 The thickness of the waveguide layer is 0.6 μm when the composition is gradually changed; y1 is gradually changed from 0.6 to 0.5;

[0054] GaAs 1-y4 P y4 The thickness of the waveguide layer on the composition gradient is 0.3 μm; y4...

Embodiment 2

[0060] A high-uniformity high-power laser epitaxial wafer adopts a GaAs substrate, and on the GaAs substrate from bottom to top, it includes: a GaAs buffer layer, a GaAs 0.49 In 0.51 P lower confinement layer, GaAs 1-y1 P y1 Compositionally graded lower waveguide layer, GaAs 0.8 P 0.2 Lower waveguide layer, GaAs 0.97 P 0.03 Quantum well layer, GaAs 0.6 P 0.4 Upper waveguide layer, GaAs 1-y4 P y4 Composition-graded upper waveguide layer, Ga 0.49 In 0.51 Confinement layer on P, Ga 0.49 In 0.51 P etch stop layer, GaAs ohmic contact layer.

[0061] In this example, GaAs 0.8 P 0.2 Lower waveguide layer and GaAs 0.6 P 0.4 The thickness of the upper waveguide layer is 18nm;

[0062] GaAs 1-y1 P y1 The thickness of the waveguide layer is 0.6 μm when the composition is gradually changed; y1 is gradually changed from 0.5 to 0.4;

[0063] GaAs 1-y4 P y4 The thickness of the waveguide layer on the composition gradient is 0.3 μm; y4 is gradually changed from 0.5 to 0...

Embodiment 3

[0069] A high-uniformity high-power laser epitaxial wafer adopts a GaAs substrate, and on the GaAs substrate from bottom to top, it includes: a GaAs buffer layer, a GaAs 0.49 In 0.51 P lower confinement layer, GaAs 1-y1 P y1 Compositionally graded lower waveguide layer, GaAs 0.7 P 0.3 Lower waveguide layer, GaAs 0.95 P 0.05 Quantum well layer, GaAs 0.8 P 0.2 Upper waveguide layer, GaAs 1-y4 P y4 Composition-graded upper waveguide layer, Ga 0.49 In 0.51 Confinement layer on P, Ga 0.49 In 0.51 P corrosion barrier layer, GaAs ohmic contact layer; its structure is as figure 1 shown.

[0070] In this example, GaAs 0.7 P 0.3 Lower waveguide layer and GaAs 0.8 P 0.2 The thickness of the upper waveguide layer is 13nm;

[0071] GaAs 1-y1 P y1 The thickness of the waveguide layer is 0.6 μm when the composition is gradually changed; y1 is gradually changed from 0.5 to 0.4;

[0072] GaAs 1-y4 P y4 The thickness of the waveguide layer on the composition gradient is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com