Waste emulsion treatment system utilizing power plant boiler

A treatment system and emulsion technology, applied in the field of waste emulsion treatment, can solve the problem of high disposal cost of waste oil, and achieve the effect of saving disposal cost, excellent environmental protection effect and proper treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

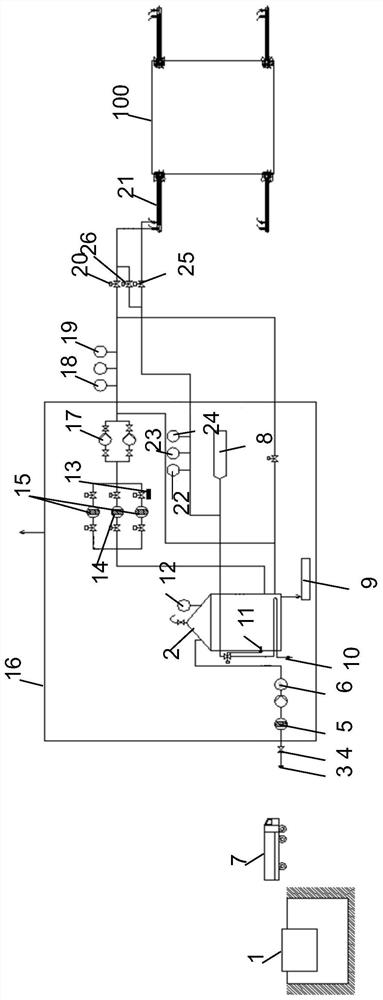

[0027] Please combine figure 1 As shown, a waste emulsion treatment system utilizing a power plant boiler provided by the present invention is connected with the boiler furnace 100 of the power plant, including:

[0028] The pretreatment device 1 is used to remove impurities with larger particles in the waste emulsion.

[0029] The storage subsystem is located at the post-work station of the pretreatment device, and is used for loading, unloading, storing and heating the waste emulsion. Including the emulsion oil tank 2, the breathing valve on the emulsion oil tank 2 is connected to the discharge port 3 through the delivery pipeline, and the delivery pipeline from the discharge port 3 to the breathing valve is also provided with a filter screen 4, an oil discharge pump 5 and a flow meter 6 in sequence . The emulsion after p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com