Sludge recycling technique

A technology of recycling and sludge, applied in dewatering/drying/concentrating sludge treatment, petroleum industry, special forms of dry distillation, etc. The effect of energy consumption, solving incomplete disposal and reducing disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

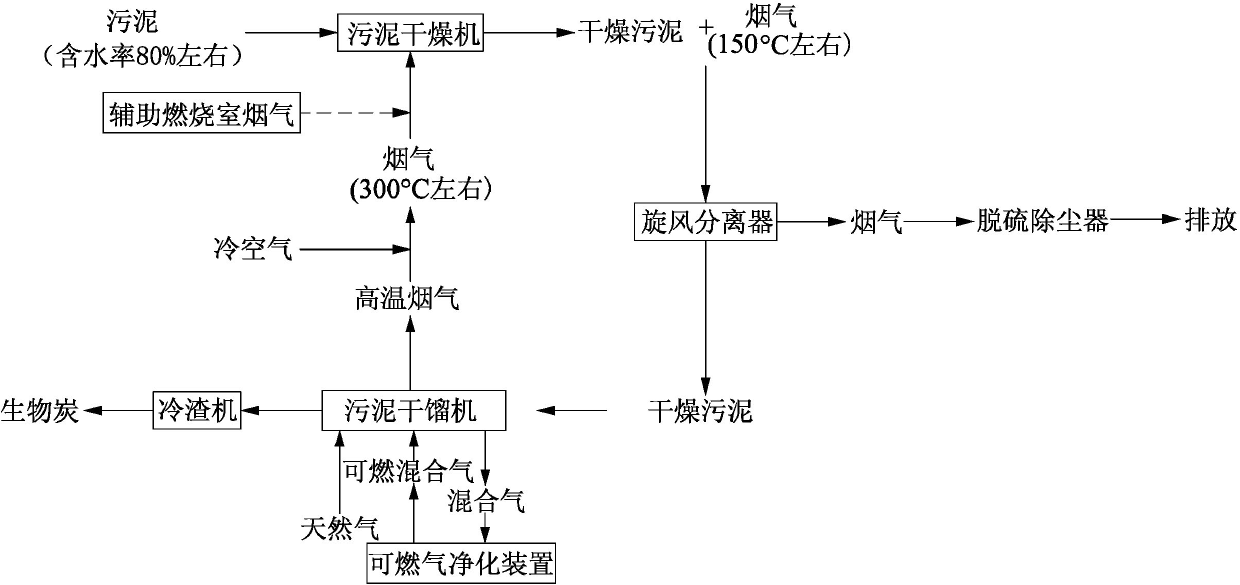

[0032] see figure 1 , and with figure 2 , figure 2 It is a preferred embodiment of the present invention, which can treat 50 tons of urban sewage plant sludge per day.

[0033] In the first step, the sludge is transported to the screw propulsion air dryer through the screw pump for low temperature direct heating drying. The drying temperature of the spiral propulsion airflow dryer is about 300 ℃, and the sludge drying process at this temperature will not produce dioxins; the heat source required for the spiral propulsion airflow dryer is mainly the waste heat of the dry distillation machine, and the auxiliary heat source is The residual heat of the flue gas in the auxiliary combustion chamber; the moisture content of the sludge after being dried by the spiral propulsion airflow dryer can be reduced from 80% to about 40%.

[0034] Among them, the sludge dryer is a spiral propulsion airflow dryer, such as image 3 As shown, it is composed of a housing 3, a blade 2, a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com