Freeze-drying protective agent for sphingomyelinase and preparation method

A freeze-drying protective agent and sphingomyelinase technology, which is applied in the biological field, can solve the problems of unsearched sphingomyelinase-related literature and methods, and achieve the effects of improving storage stability, good appearance, and reducing enzyme activity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The separation and purification of embodiment 1 sphingomyelinase

[0050] Using sphingomyelinase fermentation broth prepared by exogenous expression system as raw material, said exogenous expression system includes but not limited to Escherichia coli expression system, Bacillus subtilis expression system, insect cell expression system, mammalian cell expression system or yeast expression system system.

[0051] Taking Escherichia coli expression system as an example, the crushing and extraction method of sphingomyelinase is introduced. Optionally, in order to facilitate downstream purification, a His-tag can be added to the N-terminal or C-terminal of the target protein, or His-tag can be added to both ends.

[0052] Collect the microbial cell components containing the target protein by centrifuging the fermented Escherichia coli fermentation liquid, and then use mechanical methods such as high-pressure homogenate crushing or physical methods such as ultrasonic crushin...

Embodiment 2

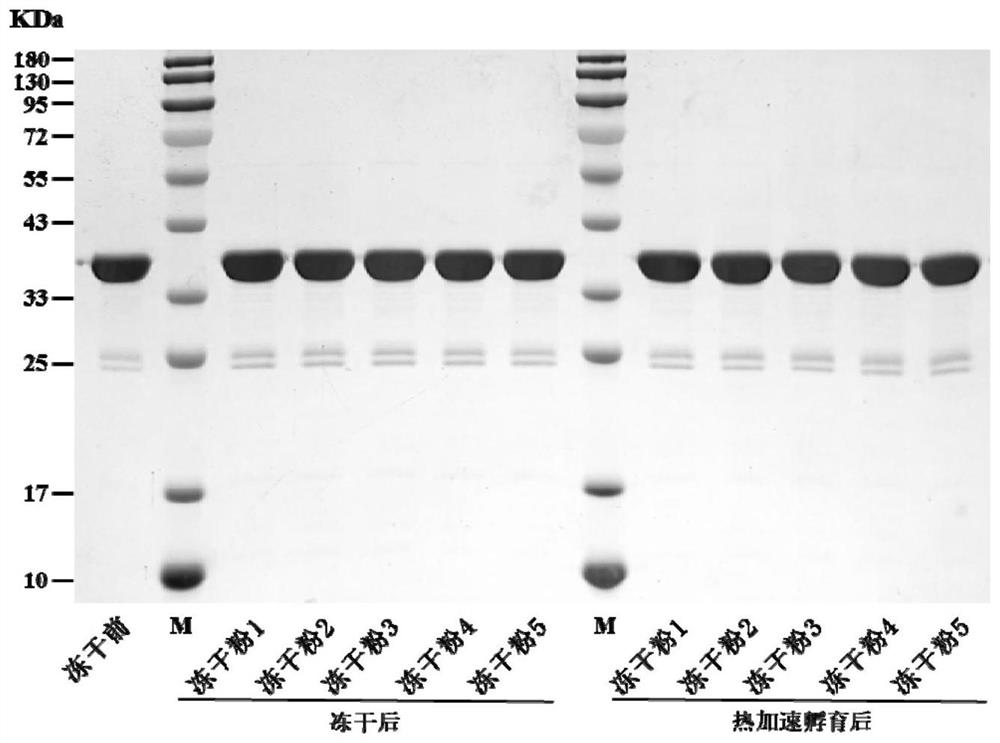

[0059] The preparation method of embodiment 2 freeze-dried powder

[0060] Pour the enzyme solution used to prepare freeze-dried powder, or the mixed solution of enzyme solution and protective agent, into a clean and sterile glass plate with a glass bottom diameter of 14cm, and ensure that the liquid level does not exceed 1cm to ensure the best sublimation effect (Excessive liquid level and excessive liquid volume will affect the sublimation efficiency), and then freeze-dried on the plate layer of the freeze dryer.

[0061] The freeze dryer program is set as follows;

[0062] a. Pre-freezing stage: set the layer temperature at -45°C for 2.5 hours; annealing temperature at -25°C for 2 hours; then lower the temperature to -45°C for 3 hours; return temperature to 1°C / min;

[0063] b. Primary sublimation: set the vacuum value below 20pa, rise from -45°C to -18°C in step a for 22 hours; in the second stage, the temperature of the sheet layer rises to -15°C, and the duration is 12h...

Embodiment 3

[0067] Prepare protective agent formula: sucrose 2~3g / L, trehalose 1~4g / L, D-mannitol 2~5g / L, glycine 1~4g / L, Tween 20 0.2mL / L~0.5mL / L, Mg 2+ 5mM~10Mm; Among them, Mg 2+ It is added in the form of salt, and the magnesium salt is selected from one or more compound of magnesium chloride, magnesium nitrate and magnesium sulfate.

[0068] Add each component in the above protective agent formula to the solution system containing the acid-base regulator. The concentration of the acid-base regulator can be controlled at 10-100mM, so that the buffering capacity of the protective agent is between pH 6.0-8.0; wherein, the acid-base regulator is selected from: citric acid-sodium hydroxide-hydrochloric acid buffer, lemon Acid-sodium citrate buffer, Tris-hydrochloric acid buffer, PIPES buffer, HEPES buffer, disodium hydrogen phosphate-sodium dihydrogen phosphate buffer or potassium dihydrogen phosphate-sodium hydroxide buffer. By adding the buffer solution, the sphingomyelinase can be m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com