Photo-thermal response super-hydrophobic anti-icing composite coating layer and preparation method thereof

A composite coating, photothermal response technology, used in coatings, anti-corrosion coatings, devices for coating liquids on surfaces, etc., can solve problems such as poor photothermal performance, lack of corrosion resistance, insufficient mechanical resistance, etc. Photothermal properties, reliable coating performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

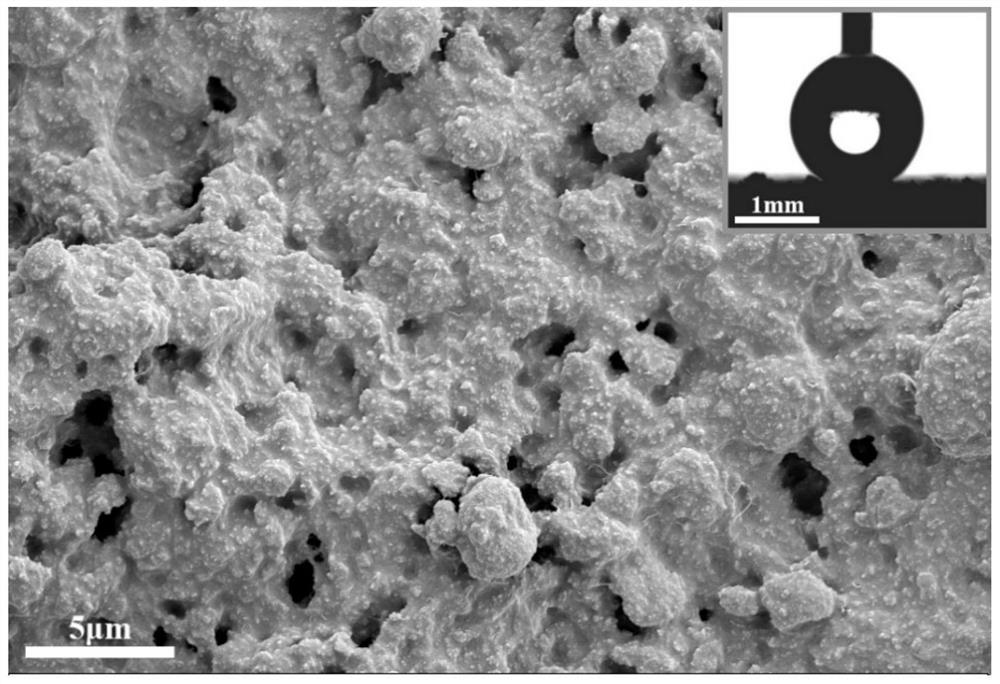

[0044] A kind of preparation of hydrophobic anti-icing coating (PVDF), comprises the steps:

[0045] (1) Preparation of mixed spraying solution: First, take 0.5g of PVDF (particle size 10-15μm, Arkema Co., Ltd., France), add it to 20ml of absolute ethanol (Tianjin Fuyu Fine Chemical Co., Ltd.), and measure orthosilicon Ethyl acetate (TEOS, produced by Shanghai Macklin Biochemical Co., Ltd., purity: 98%) 4ml was added to the above mixed solution, magnetically stirred for 10 minutes, and further ultrasonically treated for 30 minutes to obtain a uniformly dispersed suspension and a mixed spray solution;

[0046] (2) Preparation of the substrate for spraying: firstly place the glass slide (7101) in absolute ethanol for ultrasonic treatment for 10 min and then take it out to dry; mix 5 g of RTV-SR with 2 ml of n-hexane (manufactured by Shanghai Macklin Biochemical Company), 0.5ml TEOS, 0.1ml dibutyltin dilaurate were magnetically mixed and then magnetically stirred for 10min; then ...

Embodiment 2

[0050] A kind of preparation of photothermal response superhydrophobic anti-icing composite coating (CNTs), comprises the steps:

[0051] (1) Preparation of mixed spraying solution: First, take 0.05 g of multi-walled carbon nanotubes (CNTs, 10-30 nm in diameter, 10-20 μm in length, Nanjing Xianfeng Nano Material Technology Co., Ltd.), and add it to 20 ml of absolute ethanol (Tianjin Fu Yu Fine Chemical Co., Ltd.), 4 ml of tetraethyl orthosilicate (TEOS, produced by Shanghai Macklin Biochemical Co., Ltd., purity: 98%) was added to the above mixture, stirred by magnetic force for 10 min, and then ultrasonically treated for 30 min to obtain a uniformly dispersed suspension to obtain a mixed spray solution;

[0052] (2) Preparation of the substrate for spraying: firstly place the glass slide (7101) in absolute ethanol for ultrasonic treatment for 10 min, take it out and dry it, mix 5 g of RTV-SR with 2 ml of n-hexane (manufactured by Shanghai Macklin Biochemical Company), 0.5ml T...

Embodiment 3

[0057] A kind of preparation of hydrophobic anti-icing coating (not thermally treated PVDF / CNTs coating), comprises the steps:

[0058] (1) Preparation of mixed spraying solution: first, take 0.05 g of multi-walled carbon nanotubes (CNTs, diameter 10-30 nm, length 10-20 μm, Nanjing Xianfeng Nano Material Technology Co., Ltd.), PVDF (particle size 10-15 μm, France Arkema Co., Ltd.) 0.5g was added to 20ml of absolute ethanol (Tianjin Fuyu Fine Chemical Co., Ltd.), and 4ml of ethyl orthosilicate (TEOS, produced by Shanghai Macklin Biochemical Co., Ltd., purity: 98%) was measured and added In the above mixed solution, magnetically stir for 10 minutes, and further ultrasonically treat for 30 minutes to obtain a uniformly dispersed suspension, and obtain a mixed spray solution;

[0059] (2) same as embodiment 1 step (2), obtain semi-viscous fluid state SR-slide glass substrate;

[0060] (3) Spray the mixed solution described in step (1) vertically on the semi-viscous fluid state SR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com