Preparation and application of coating forming type TPU film and coating forming type TPU paint surface protective film

A protective film and type technology, applied in the direction of film/flaky adhesives, adhesives, etc., can solve the problems that cannot meet the requirements of the optical film surface, uneven thickness of TPU film, and investors are discouraged, etc., to achieve automatic repair Surface scratches, excellent anti-aging performance, excellent sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

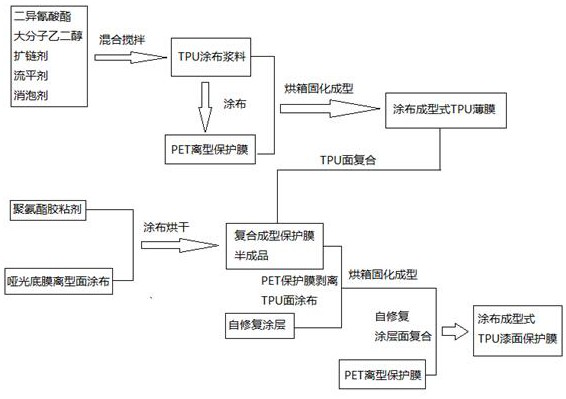

[0022] Example: see above figure 1 , figure 1 It is the flow chart of the whole production process of the present embodiment. Such as figure 1 As shown, the manufacturing process of the coated TPU film of the present embodiment comprises the following steps:

[0023] S11 Dissolve diisocyanate in a solvent, add macromolecular ethylene glycol to prolong the reaction time, and then add chain extender, leveling agent, defoamer, etc. to prepare TPU pre-coating;

[0024] S12 Execute the stirring program, in detail, stir at a speed of 450r / min with the stirrer for at least 30 minutes;

[0025] S13 Execute the coating procedure; in detail, use a continuous and stable feeding system to transport the material to the high-precision coating head, and evenly coat the release surface of the PET release protective film to form a layer of TPU film with uniform thickness ;

[0026] S14 Execute the drying and curing procedure; the coated TPU film layer is transported to the oven through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com