Preparation method of nano metal oxide

A nano-metal and oxide technology, applied in the preparation of oxide/hydroxide, chemical instruments and methods, nanotechnology, etc., can solve the problems of long time, low product yield, and unsuitable for large-scale commercial production. Few experimental parameters, high purity and yield, and the effect of morphology control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

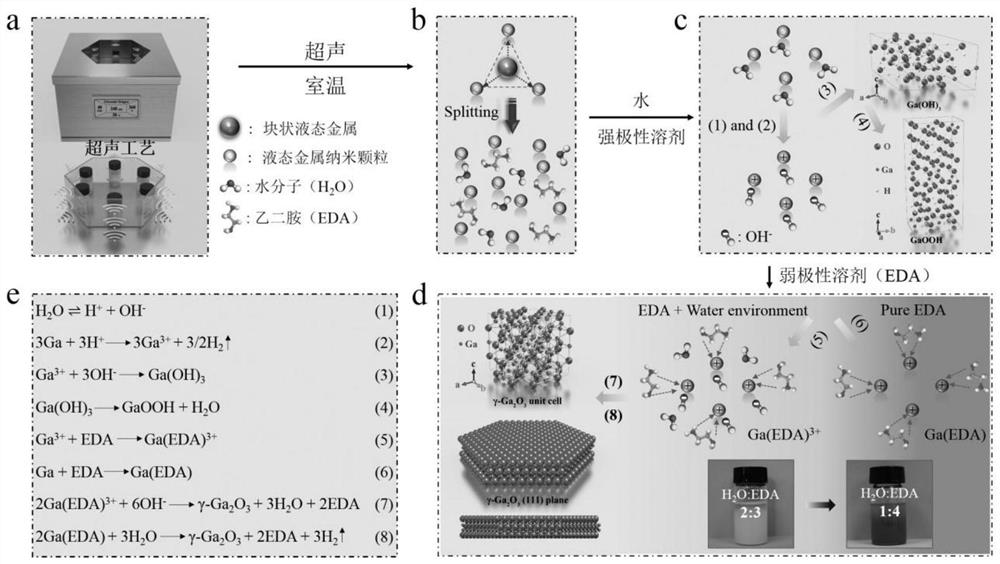

[0045] A method for preparing nanometer metal oxides, comprising: using ultrasonic waves to treat a mixture of simple metals, water and organic solvents.

[0046] The nano metal oxide prepared by the present invention refers to a metal oxide with at least one dimension in the range of nanometer size (nanosize refers to the length dimension of ≤100nm) in three-dimensional space, which can be zero-dimensional, one-dimensional or two-dimensional nanometer Material. Zero-dimensional nanomaterials refer to three-dimensional nanoscale materials, such as nanoparticles, etc.; one-dimensional nanomaterials refer to two-dimensional nanoscale materials, such as nanowires, nanorods, nanotubes, etc.; two-dimensional nanomaterials refer to One dimension is in the nanoscale range, such as nanosheets, nanofilms, etc. Nano metal oxides with different structures and morphologies can be obtained by using different metal elements and / or adjusting process conditions.

[0047] Ultrasonic treatmen...

Embodiment 1

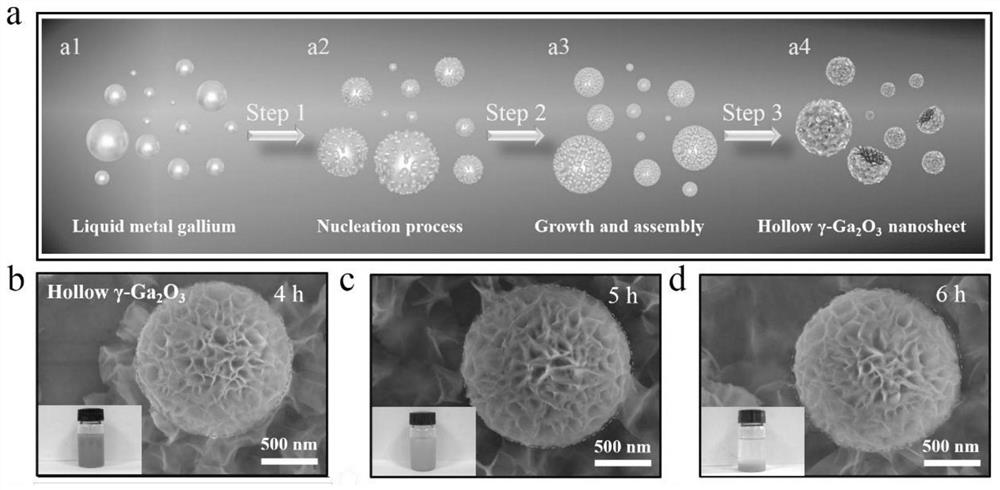

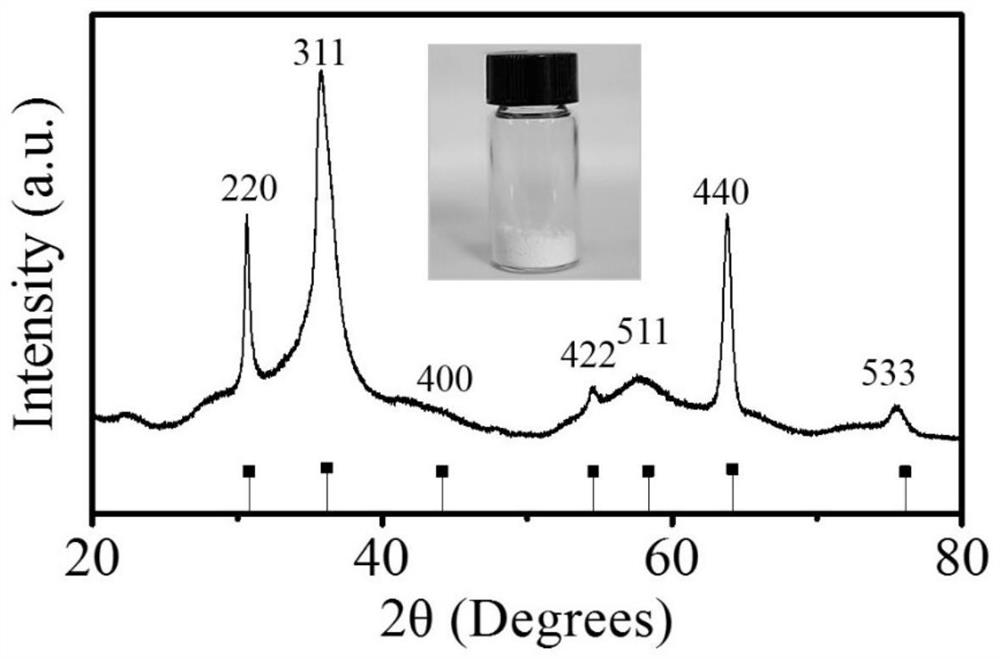

[0071]Measure 6 mL of ultrapure water and 9 mL of ethylenediamine in a glass vial to form a mixed solvent, add 1 mmol (69.72 mg) of liquid metal gallium into the mixed solvent, and place the glass vial in an ultrasonic two-dimensional material stripper (Scientz-CHF- 5A, Xinzhi, China) for ultrasonic treatment, the frequency of ultrasonic treatment is 40KHz, and the power is adjusted to 252W; under stirring conditions, ultrasonic treatment is performed for 4h; after ultrasonic treatment, it is naturally cooled to room temperature, filtered, and the obtained solution is stored and recycled to reduce reagents consumption, the obtained white powder was washed 3 times with 75v / v% ethanol solution, and finally dried at 80°C for 12h to obtain γ-Ga 2 o 3 nanomaterials. After weighing, the obtained γ-Ga 2 o 3 The mass of the nanomaterial is 86.02mg, and the calculated yield is 91.8%.

Embodiment 2

[0073] Example 2 Ultrasonic treatment for 5 hours, other experimental steps are the same as in Example 1. After weighing, the obtained γ-Ga 2 o 3 The quality of the nanomaterial is 85.53 mg, and the calculated yield is 91.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com