All-plastic composite toothpaste tube sheet suitable for being recycled and production method of all-plastic composite toothpaste tube sheet

A production method and technology of toothpaste tubes, applied in all-plastic composite toothpaste tube sheet and its production field, can solve the problems of low value of recycling and reuse, difficulty in recycling, etc., achieve good forming effect, improve heat sealing strength, The effect of high surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

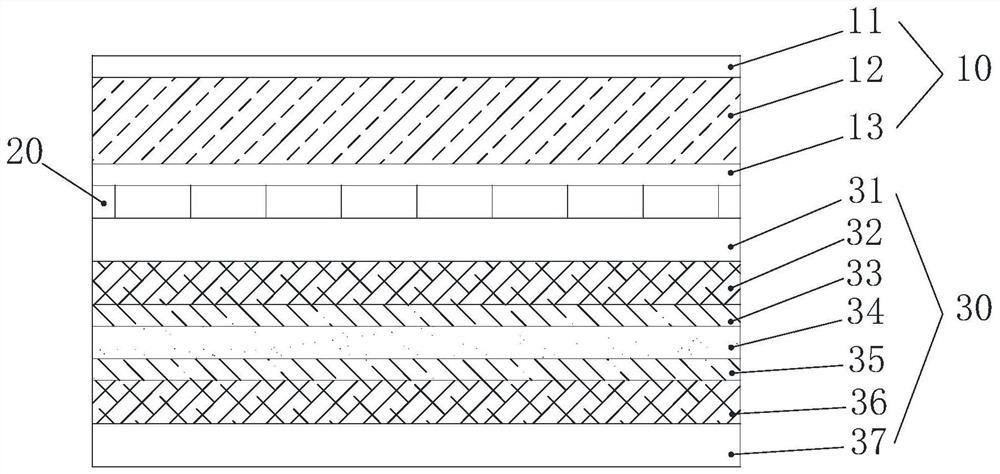

[0051] Such as figure 1 As shown, an all-plastic composite toothpaste tube sheet suitable for recycling, the total thickness of the sheet is 232-164 μm, and the surface film 10, the coating layer 20 and the inner film 30 are sequentially formed from the outside to the inside according to the thickness ratio of 5.7:1. : 5.7 composition.

[0052] The surface film 10 is composed of 52.8wt% high-density polyethylene, 30.6wt% metallocene polyethylene, 13.2wt% white color masterbatch and 3.4wt% processing aid. Among them, the high-density polyethylene is B4460AB high-density polyethylene of Sabic company, the metallocene polyethylene is Exxon company's brand 3505MC and Japan's Mitsui brand SP1520 metallocene polyethylene, and the white masterbatch is UF880M of Dainippon Ink Chemical Co., Ltd. Color masterbatch, the processing aid is the brand 10991-K processing aid of An Color Matching Company.

[0053] The coating layer 20 is 100wt% Dow chemical grade 722S low density polyethylen...

Embodiment 2

[0068] The production method steps of the all-plastic composite toothpaste tube sheet suitable for recycling in embodiment 1 are as follows:

[0069] S1. Prepare the raw materials of each layer in the surface film 10 according to the proportion, put them into the mixer and mix them evenly, and then send them into the extruder to melt, and follow the first layer 11, the second layer 12 to the third layer 13 in sequence Arrangement order, use extruder to co-extrude blown film, make surface film 10.

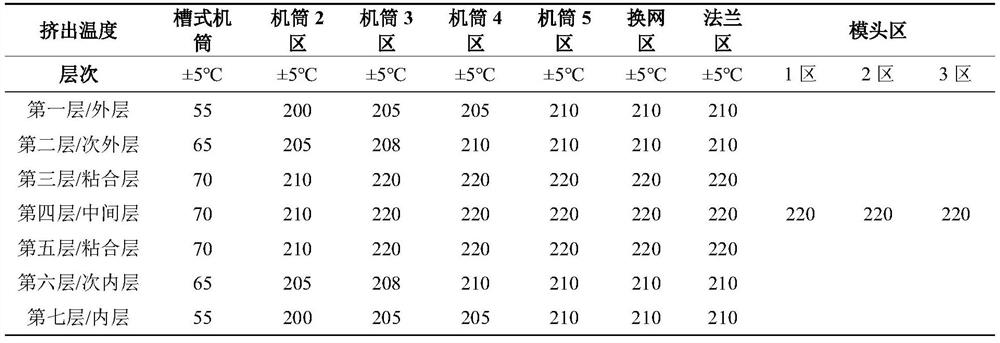

[0070] In this process, the extruder screw diameter is 90mm, 100mm and 90mm, and the die head diameter is 50mm; the temperature setting of the extruder is as follows in Table 1:

[0071]

[0072] The above-mentioned layers of raw materials are extruded at high temperature by an extruder to form a melt, and then pass through a filter screen consisting of three layers of 100 mesh, 150 mesh, and 100 mesh. Then pass through the die distributor to form a ring-shaped bubble tube film,...

Embodiment 3

[0086] Composite sheets prepared by the present invention are recorded as experimental groups 1-3, and the composition and structure of the inner film 30 of the composite sheets are adjusted as comparison groups 1 and 2 for performance testing.

[0087] The compositional data of experimental groups 1-3 and comparative groups 1 and 2 are shown in Table 3 below, and the numbers in the table are all mass fractions.

[0088]

[0089] The main physical performance indicators of the above five groups of sheets were tested, and the results are shown in Table 4 below:

[0090]

[0091] It can be seen from Table 4 that the tensile strength of the composite sheet increases with the increase of the ratio of metallocene polyethylene, and the heat sealing performance of the composite sheet also increases accordingly. From the data of the experimental group and the comparative group, it can be seen that the drop impact strength has been improved to a certain extent with the adjustment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com