Matt polyethylene film suitable for intaglio printing and preparation process thereof

A gravure printing process and polyethylene film technology, applied in the field of hygiene material packaging, can solve the problems affecting the physical properties of PE film, printing color registration, polyethylene printing difficulty coefficient, poor color registration accuracy, etc., to achieve good film surface appearance, reduce The crystal point condition of the film surface and the effect of reducing the wire drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

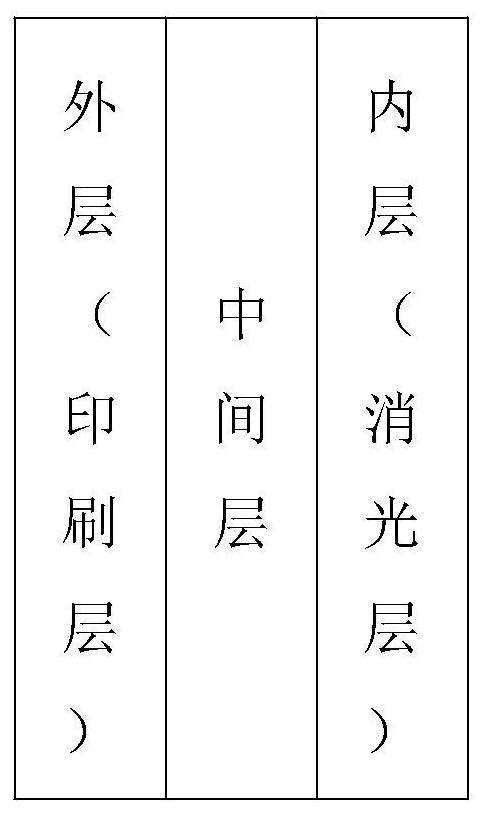

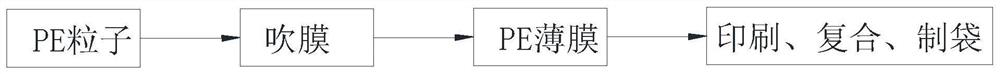

[0028] S1. According to the formula composition of the outer layer, the middle layer and the inner layer of the film, weigh the components of the parts by mass respectively, wherein the outer layer includes 72.5 parts by mass of 1002AY produced by Exxon and 25 parts by mass of the brand FT5230 produced by Borealis, 1.5 parts by mass of processing aids and 1 part by mass of slip agent; the middle layer includes 75 parts by mass of the brand 1002AY produced by Exxon and 25 parts by mass of the brand produced by Borealis FT5230; the inner layer includes 98.5 parts by mass of the brand FB2230 produced by Borealis, 1 part by mass of processing aids and 0.5 parts by mass of slippery agent, and the particles of each layer are respectively dropped into the corresponding 3 extruders Extruded at high temperature to form a melt.

[0029] S2. Pass the melt in step S1 through the filter screen and the die distributor in sequence to form a ring-shaped bubble tube film, cool and shape it in ...

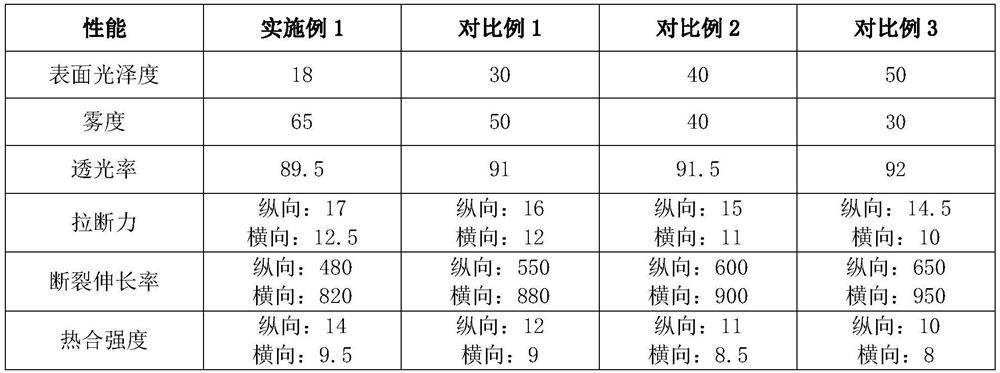

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com