Method for producing anti-contact fatigue hypereutectoid steel rail

A contact fatigue and hypereutectoid technology, which is applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems affecting line operation efficiency and safety, hypereutectoid rail contact fatigue, etc., to achieve good wear resistance, Excellent contact fatigue resistance and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

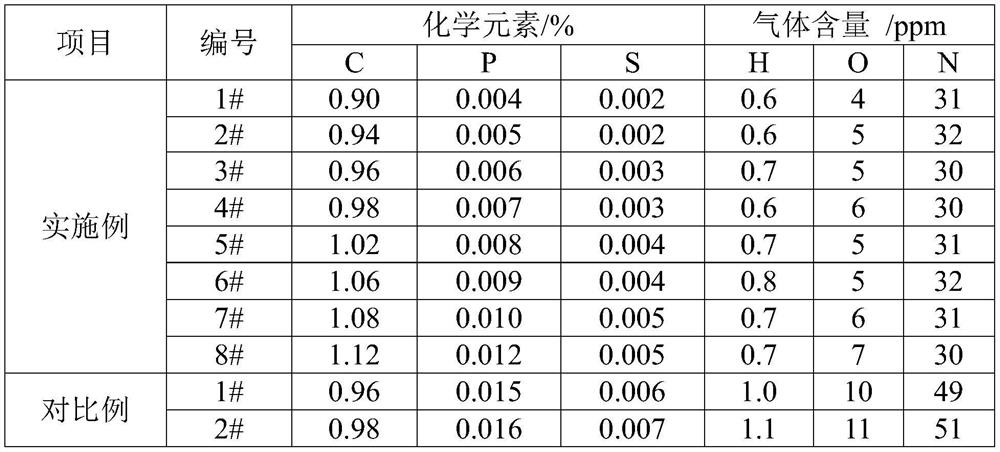

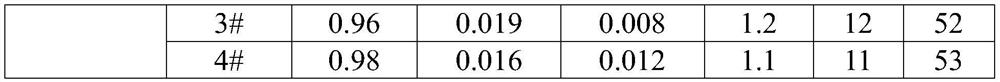

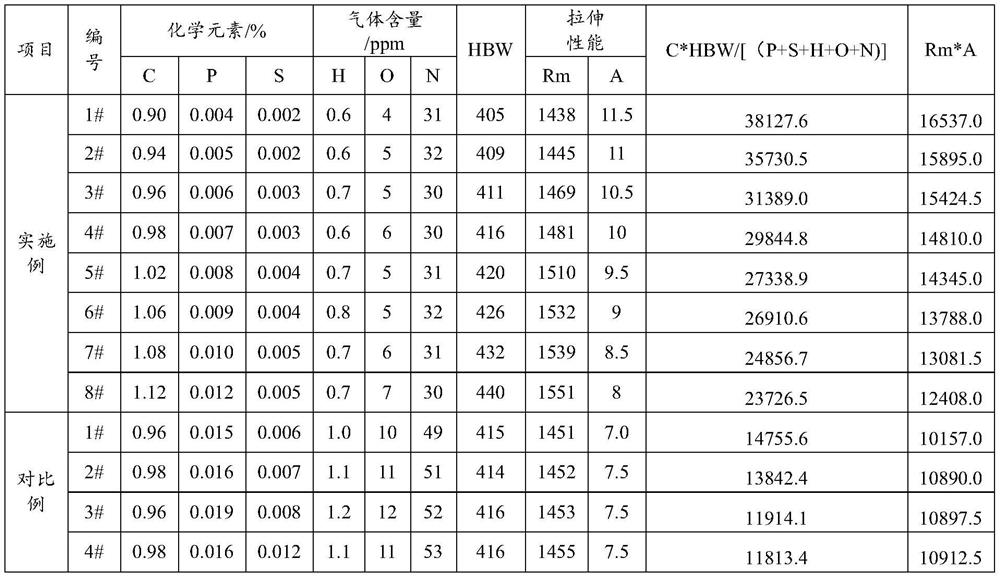

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with specific examples.

[0039] The main technological process of out-of-furnace refining includes LF refining and RH refining.

[0040] LF refining (ladle refining furnace method): Heating by electric arc, blowing argon at the bottom of the ladle and stirring.

[0041] Process advantages

[0042] 1) Arc heating has high thermal efficiency, large temperature rise range, and temperature control accuracy can reach ±5°C;

[0043] 2) With the function of stirring and alloying, argon blowing and stirring can easily realize narrow-range alloy composition control and improve product stability;

[0044] 3) Less equipment investment, low refining cost, suitable for producing ultra-low sulfur steel and ultra-low oxygen steel.

[0045] Key points of LF refining production process

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com