Carburizing heat treatment process for fatigue-resistant metal sliding block

A technology of fatigue resistance and sliding block, applied in the field of heat treatment, can solve the problem of reducing the ability of inward diffusion, and achieve the effect of smoothing the hardness gradient and improving the contact fatigue performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

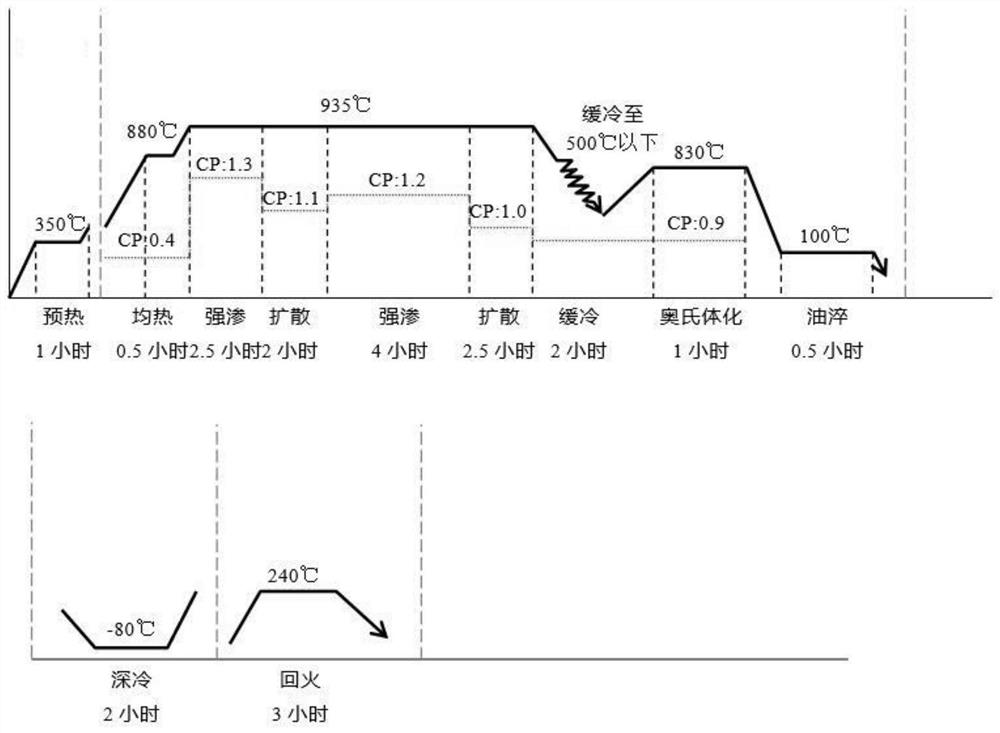

[0024] see figure 1 , CP in the figure refers to the carbon potential in the furnace.

[0025] The carburizing heat treatment process of the fatigue-resistant metal slider includes the following steps:

[0026] S1. Put the slider into the preheating furnace to preheat to 350°C, and the preheating time is 1h;

[0027] S2. Put the slider into a box-type controlled atmosphere carburizing furnace for carburizing and quenching; specifically include

[0028] S21, soaking to 880°C, soaking time is 0.5h, CP is 0.4;

[0029] S22. Heating to 935°C for the first intensive infiltration for 2.5 hours and a CP of 1.3; for the first diffusion for 2 hours and a CP of 1.1; then for the second intensive infiltration for 4 hours and a CP of 1.3 It is 1.2; then carry out the second diffusion, the time is 2.5h, and the CP is 1.0; prevent one-stage high carbon potential and strong infiltration from causing surface carbon accumulation and cementite; the design of decreasing carbon potential makes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com