Large flexible heat treatment automatic production line with protective atmosphere and production method

An automatic production method and automatic production line technology, applied in the field of heat treatment, to achieve the effects of improving quality monitoring, large output, and liberating labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

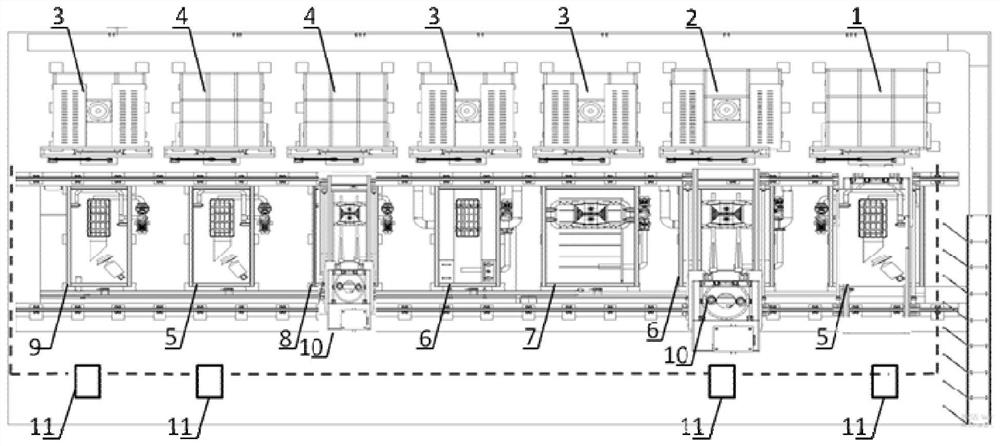

[0038] The present invention provides a large flexible heat treatment automatic production line with a protective atmosphere, such as figure 1 As shown, a computer integrated control management system can be used to implement a mechanized automatic loading and unloading material, the heat treatment process parameters automatically, online monitoring and real-time regulation of a heat treatment automation production line, including large high temperature quenching heating furnace 1, big back fire heating furnace 2, small back Fire heating furnace 3, small high temperature quenching heating furnace 4, water tank 5, oil tank 6, cleaning tank 7, salt water tank 8, organic solvent tank 9, taking a vehicle 10 and a superbatch 11, in addition, there is an intelligent control system.

[0039] Preferably, the three high-temperature quenched heating furnaces are inconsistent, and a high temperature quenching heating furnace 1 having a size of 1.2 × 1 × 1.4 m is comprised of a high-temperatu...

Embodiment 2

[0048] The present invention also provides a heat treatment automated production line process, and the specific steps are as follows:

[0049] Step 1: Check: The operator checks the production line equipment in front of the production line, determines the production line in normal state, with production conditions

[0050] Step 2: Head: The upper mesh is lowered, the operator will support the auxiliary shaft part, put it in the air discharge plate placed on the upper stage, and the upper stage rises to the limited position waiting to take the feed vehicle to remove ;

[0051] Step 3: Process Preparation: The operator enters the automatic control system on the console, the insulation temperature is set to 1040 ° C, the holding time is 60 min, and the water is cold for 10 min. Select the upper material 11, the heat treatment furnace 1 and the water tank 5 for production, and then check the production line peripheral situation to produce production;

[0052] Step 4: Automatic tapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com