Firework with integral module explosive filling structure in open mode and preparation method thereof

A technology for shells and buds, which is applied to the field of shells with an integral modular budding structure and their preparation, can solve the problems of unsatisfactory bud effect, unsatisfactory ignition performance, hidden dangers in the safety of shells, and the like. Improve budding effect, improve ornamental effect and environmental performance, good quality stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

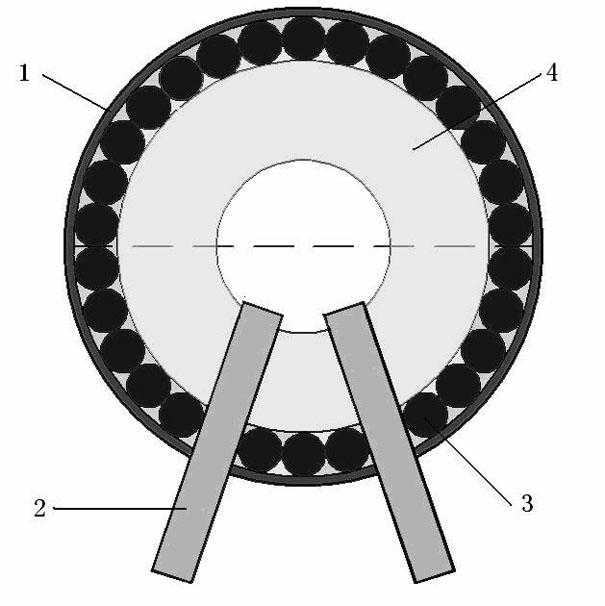

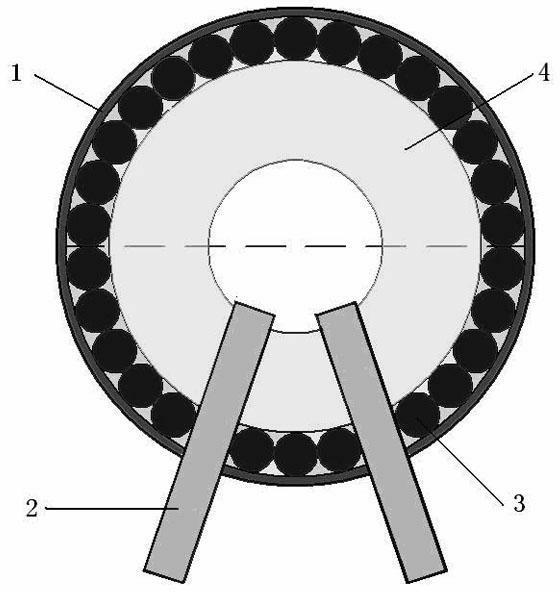

[0060] combine figure 1 , select the 3-inch fireworks bomb as an example, the outer spherical shell diameter is 76mm, and the thickness is 3mm.

[0061] Granular microporous fireworks medicine is prepared by using single-base waste powder containing 97.0% nitrocellulose and 1.0% diphenylamine (stabilizer). The raw material is preliminarily crushed to control the particle diameter to no more than 3mm, and the wet powder with water is added to the molding equipment. In the state of stirring, add ethyl acetate solvent 10 times the mass of the pellets, stir and dissolve at 45°C-50°C for 30-60min, and then continuously add 0.5% aqueous solution of potassium nitrate to the system; Carry out emulsification and foaming operation. In this step, continue to add 0.5% potassium nitrate aqueous solution. The amount of potassium nitrate aqueous solution added is 6 times the mass of the medicine grains, and then continue to stir at a temperature of 50-60°C for 30min-60min. When the temperat...

Embodiment 2

[0068] combine figure 1 , using the same charge structure as in Example 1, the preparation process of the granular micropore fireworks drug is the same as in Example 1, and the preparation process of the budding drug premix for the integral module charge is also the same as in Example 1, except that The drying step of the two hemispheres is omitted in the process of popping and charging the fireworks, and the complete spheres are prepared and then dried together, and the drying time is extended by 24 hours. The bud-opening test shows that the firing rate of Liangzhu is 100%, and the bud-opening diameter is about 50 meters.

Embodiment 3

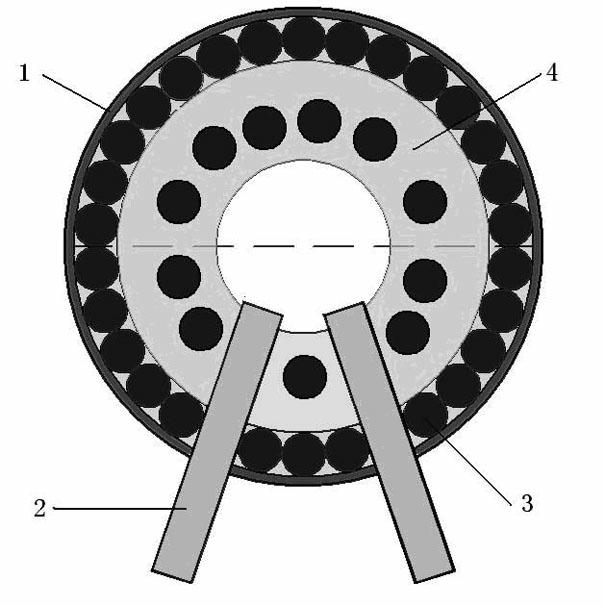

[0070] combine figure 2 , using the same process and raw materials as in Example 1 to make the fireworks shell of the modular charge structure. The preparation process of the granular micro-pore fireworks medicine is the same as that of Example 1, and the preparation process of the bud-opening drug premix for integral module filling is also the same as that of Example 1, only the filling structure is changed, and the filling order is as follows: step a, the first A layer of bright beads is arranged on the inside of half of the shell of the shell, and then the first layer of budding medicine is filled into the inside of the first layer of bright beads, and the second layer of bright beads is filled into the inside of the first layer of budding medicine premix ; Fill the second layer of bud-opening drug premix block into the inner side of the second layer of bright beads, leaving some space in the center of the shell; use the same method as above to fill the other half of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com