Flame-treatment-free high-foaming-ratio polypropylene foam material and preparation method thereof

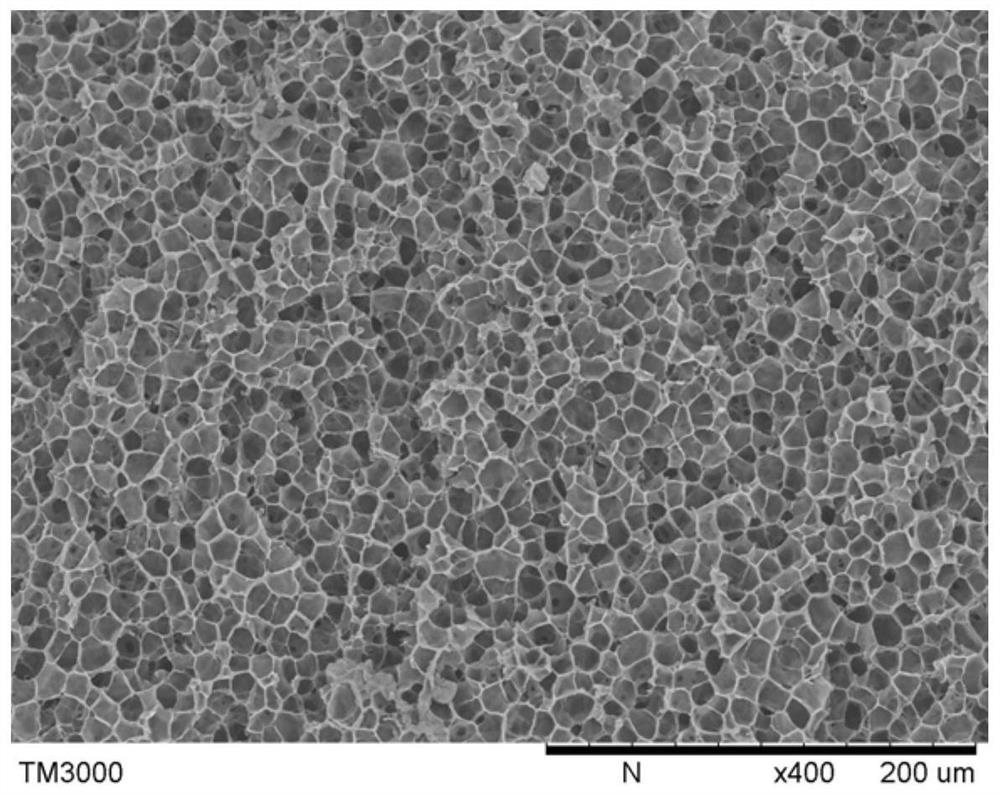

A technology for polypropylene materials and foaming materials, which is applied in the field of flame-free treatment of high-expansion-ratio polypropylene foaming materials and its preparation, can solve problems such as poor compatibility, loss of use functions, and cell collapse, and achieve low cost, Good hydrophilicity and uniform cell density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

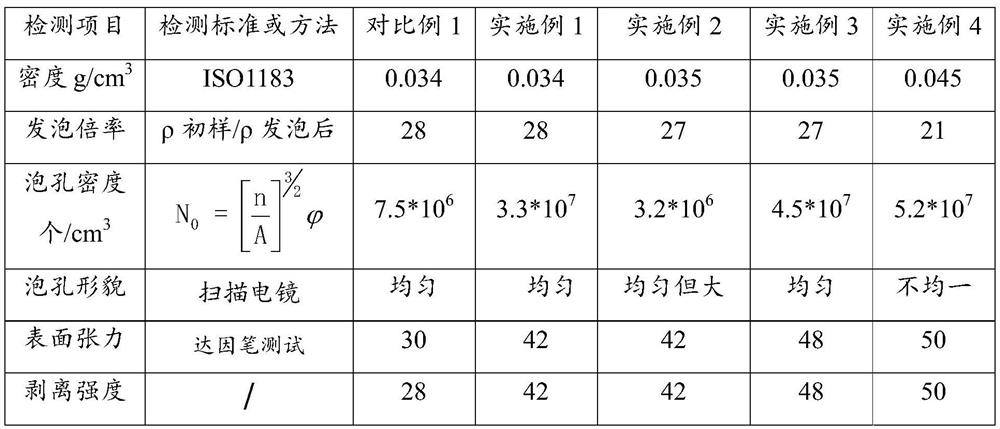

Embodiment 1

[0034] A preparation method for non-flame treatment of high expansion ratio polypropylene foam material, comprising the following steps:

[0035] (1) Weigh the following components by weight: 91 parts of polypropylene, 5 parts of 5000 mesh talcum powder, 2 parts of POE-g-MAH, 2 parts of amphiphilic block copolymer, 0.5 part of antioxidant, nucleating 0.2 parts of antistatic agent, 0.3 parts of antistatic agent, blend the above raw materials in a low-speed mixer for 20 minutes, and add them to the twin-screw extruder. 200°C, 200°C, 200°C, 205°C, 205°C, 205°C, 205°C, 210°C, 210°C, the machine head is 200°C, the mixed material is melted and plasticized, kneaded, extruded, cooled, cut granules and dried to obtain a modified polypropylene material;

[0036] (2) Extrude the modified polypropylene material into a certain volume of sheet material through a single screw, put the sheet material into a mold suitable for sheet material foaming, and control the foaming process parameters ...

Embodiment 2

[0038] The difference between Example 2 and Example 1 is that when the modified polypropylene material is prepared in step (1), 5 parts of talcum powder with a mesh size of not less than 7000 meshes is selected as the filler, and the contents of other components and process parameters remain unchanged.

Embodiment 3

[0040] The difference between Example 3 and Example 1 is that when the modified polypropylene material is prepared in step (1), the parts by weight of polypropylene are 89 parts, the parts by weight of the amphiphilic block copolymer are 3 parts, and the content of other components and process parameters remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com