Dyed flame-retardant cotton fabric and one-bath one-step processing method thereof

A processing method and flame-retardant cotton technology, applied in the field of textile dyeing and finishing, can solve the problems of formaldehyde release, high production and processing costs, high water and energy consumption of flame-retardant cotton fabrics, and achieve low processing costs, good flame-retardant durability, High color fastness to washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

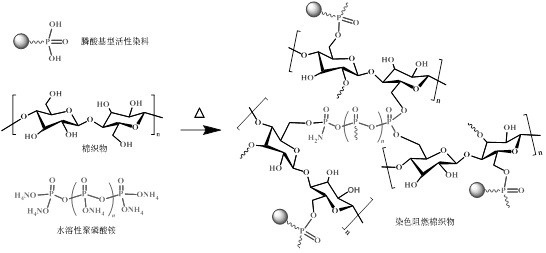

Method used

Image

Examples

Embodiment 1

[0043] (1) Prepare a one-bath dyeing flame retardant finishing solution

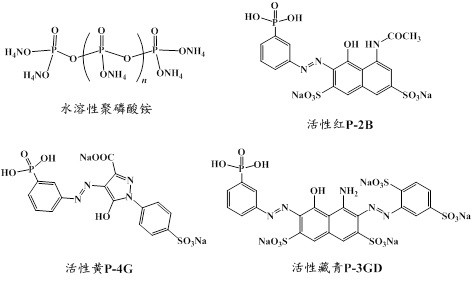

[0044] Water-soluble ammonium polyphosphate, reactive yellow P-4G (molecular formula such as figure 1 , a kind of phosphonic acid-based reactive dye), urea, and dicyandiamide were added to water, heated and stirred to dissolve, and 300 g of 11% water-soluble ammonium polyphosphate, 3% reactive yellow P-4G, and 3% urea were prepared , 5% dicyandiamide dyeing flame retardant finishing solution.

[0045] (2) Cotton fabric dyeing and flame retardant one-step processing

[0046] Soak 50 g of cotton fabric in the above finishing solution at 50 o C was treated for 30 minutes, taken out, dipped twice and rolled twice, and the excess rolling rate was controlled to be about 150%. o C, baked for 5 min, washed with water, and dried to obtain dyed flame-retardant cotton fabric.

[0047] Here, the two-dipping and two-rolling referred to here are conventional techniques in this field, which is specifically embodie...

Embodiment 2

[0052] (1) Prepare a one-bath dyeing flame retardant finishing solution

[0053] Add water-soluble ammonium polyphosphate, active yellow P-4G, urea, and dicyandiamide to water respectively, heat and stir to dissolve, and prepare 400 g containing 15% water-soluble ammonium polyphosphate, 0.5% active yellow P-4G, and 3% urea , 5% dicyandiamide dyeing flame retardant finishing solution.

[0054] (2) Cotton fabric dyeing and flame retardant one-step processing

[0055] Soak 50 g of cotton fabric in the above finishing solution at 60 o C was treated for 20 min, taken out, dipped twice and rolled twice, and the excess rolling rate was controlled to be about 110%, at 175 o C, baked for 5 min, washed with water, and dried to obtain dyed flame-retardant cotton fabric.

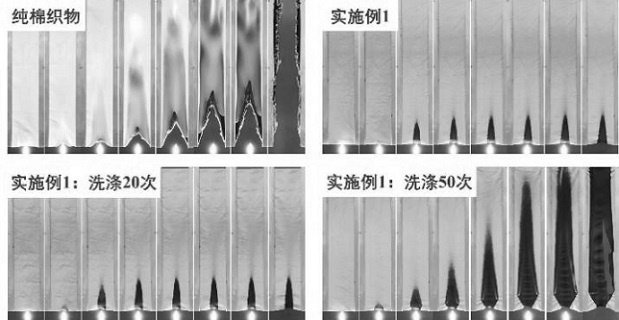

[0056] The K / S value of the dyed flame-retardant cotton fabric is 5.42, the limiting oxygen index value is 35.9%, and it is self-extinguishing when it leaves the fire during the vertical burning test. After washing ...

Embodiment 3

[0058] (1) Prepare a one-bath dyeing flame retardant finishing solution

[0059] Water-soluble ammonium polyphosphate, active navy blue P-3GD (molecular formula such as figure 1 , a kind of phosphonic acid-based reactive dye), urea, and dicyandiamide were added to water, heated and stirred to dissolve, and 750 g of 10% water-soluble ammonium polyphosphate, 0.5% active navy blue P-3GD, and 1% urea were prepared , 3% dicyandiamide dyeing flame retardant finishing solution.

[0060] (2) Cotton fabric dyeing and flame retardant one-step processing

[0061] Soak 50 g of cotton fabric in the above finishing solution at 70 o C was treated for 10 minutes, taken out, dipped twice and rolled twice, and the excess rolling rate was controlled to be about 120%. o C, baked for 4 minutes, washed with water, and dried to obtain dyed flame-retardant cotton fabrics.

[0062] The K / S value of the dyed flame-retardant cotton fabric is 5.27, 5.06 after washing 20 times, and 4.91 after washing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com