Preparation method of fusiform silicon dioxide composite fiber

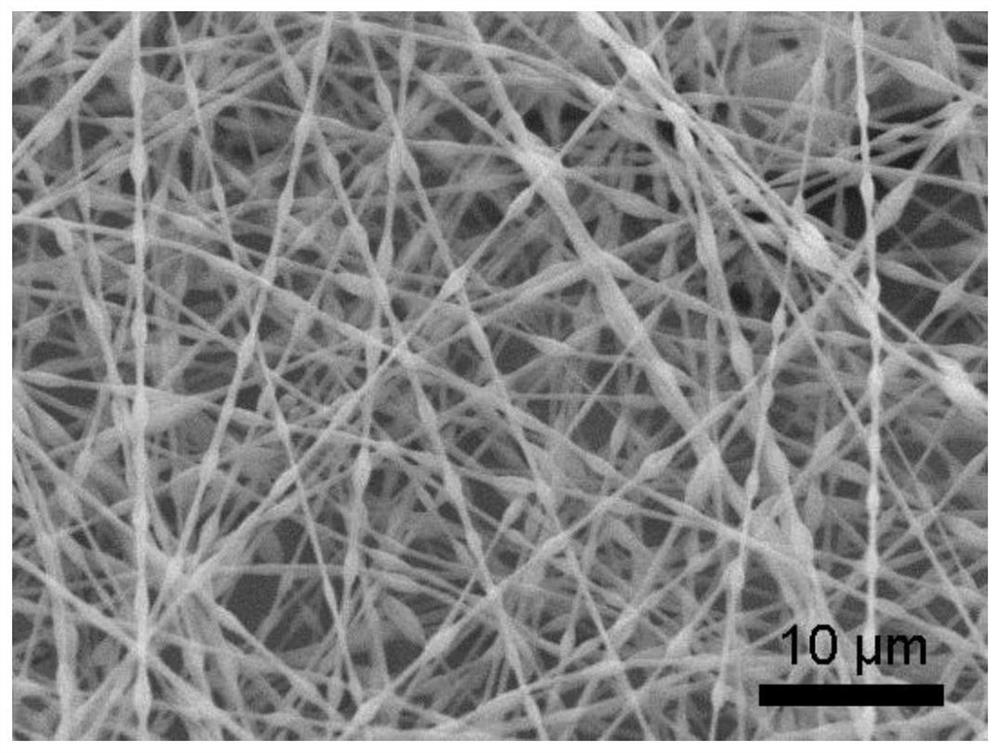

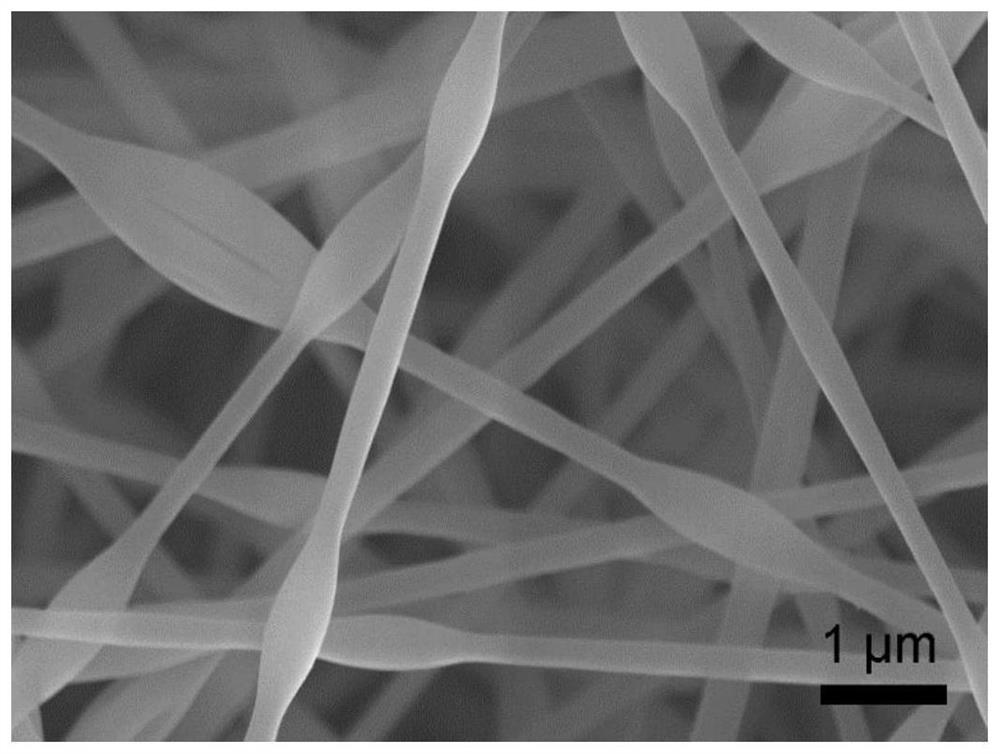

A technology of silica and composite fibers, applied in fiber processing, fiber chemical characteristics, electrospinning, etc., can solve the problems of poor interface bonding with polymer matrix, uneven distribution of inorganic phases, uneven bead size, etc. Achieve the effect of easy mass production, uniform inorganic phase distribution, and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the spindle-shaped silica composite fiber of the present invention uses polymers and silica precursors as main raw materials; the silica precursors are hydrolyzed under the action of an acidic catalyst to form silica sol; silica The sol is mixed with the polymer solution to obtain a uniform and viscous mixed solution; the mixed solution is made of a smooth surface, uniform bead size, high dispersibility and good hydrophilicity by using electrospinning technology fiber; the specific steps are as follows:

[0032] (1) The polymer powder is dissolved in an organic solvent to obtain a clear, viscous polymer solution; the polymer is polyacrylonitrile (PAN), polyvinylpyrrolidone (PVP), polymethylmethacrylate One or both of (PMMA); the organic solvent is one or both of N,N-dimethylformamide, dimethylacetamide, dimethyl sulfoxide; the polymer and The mass volume ratio of organic solvent is 0.05~0.3:1g / ml;

[0033] (2) After the silica precursor is mi...

Embodiment 1

[0036] Embodiment 1: Weigh 0.2g PAN and PVP powder in glass container respectively, after adding N,N-dimethylformamide therein, stir 12h under the condition of 600rpm, the mass volume ratio that obtains polymer and organic solvent is 0.15:1g / ml PAN / PVP mixed solution; under the catalysis of 1mol / L HCl solution, hydrolyze methyl orthosilicate for 4h to obtain a uniform silica sol; pipette the silica sol with a pipette gun, Add it into the PAN / PVP mixed solution and stir it well for 2 hours to obtain PAN-PVP-SiO with a silicon dioxide content of 20%. 2 Mixture; extract PAN-PVP-SiO with a glass needle 2 For the mixed solution, set the electrostatic field voltage to 15KV, the flow rate to 1ml / h, and the distance from the tip of the glass needle tube to the receiving plate to be 15cm, so that the PAN-PVP-SiO 2 The spinning solution forms spindle-shaped fibers under the action of electrostatic field repulsion and surface tension, and is received on a receiving plate with aluminum f...

Embodiment 2

[0038] Example 2: Weigh 0.08g of PAN and PVP powder respectively in a glass container, add N,N-dimethylformamide / dimethyl sulfoxide to it, the volume ratio is 8:2, and stir at 800rpm for 24h , to obtain a PAN / PVP mixed solution with a mass volume ratio of polymer to organic solvent of 0.06:1g / ml; under the catalysis of 1mol / L HCl solution, hydrolyze methyl orthosilicate at 60°C for 2h to obtain a uniform Silica sol: pipette the silica sol with a pipette gun, add it to the PAN / PVP mixture, and stir thoroughly for 4 hours to obtain PAN-PVP-SiO with a silica content of 30%. 2 Mixture; extract PAN-PVP-SiO with a glass needle 2 For the mixed solution, set the electrostatic field voltage to 20KV, the flow rate to 1.5ml / h, and the distance from the tip of the glass needle to the receiving plate to be 13cm, so that the PAN-PVP-SiO 2 The spinning solution forms spindle-shaped fibers under the action of electrostatic field repulsion and surface tension, and is received on a receiving p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com