Electrochromic material, device and preparation method thereof

A technology of electrochromic materials and electrochromic devices, which is applied in the field of electrochemical devices and can solve problems such as poor bistable properties, influence, and poor transmittance changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

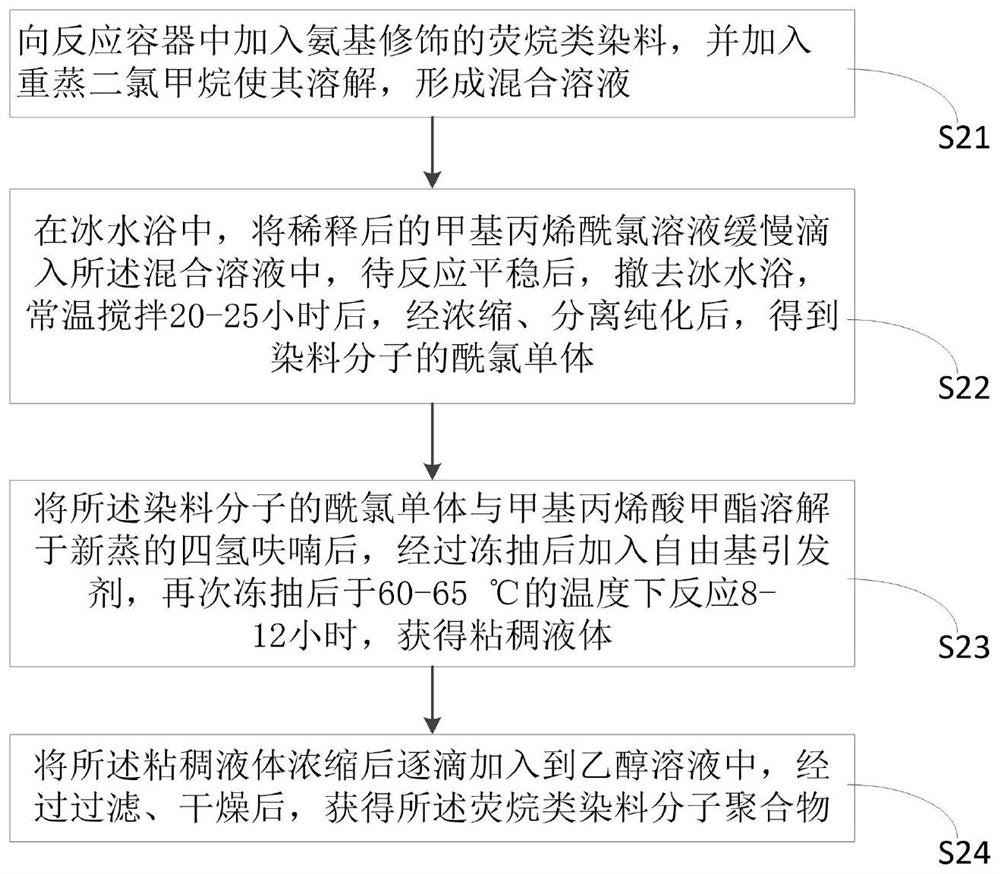

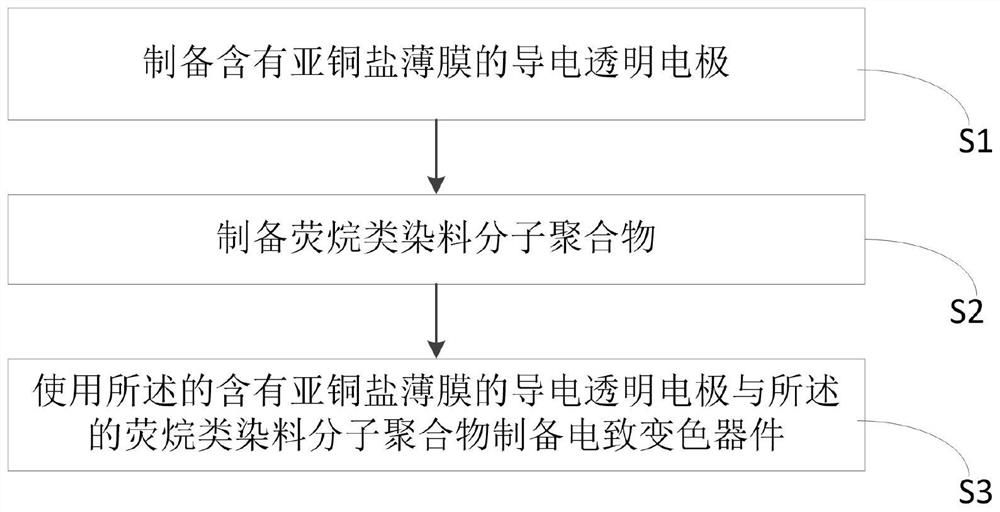

[0056] combine image 3 As shown, another embodiment of the present invention provides a method for preparing an electrochromic device, comprising the following steps;

[0057] Step S1, preparing a conductive transparent electrode containing a cuprous salt film;

[0058] Step S2, preparing a polymer of fluoran dye molecules;

[0059] Step S3, using the conductive transparent electrode containing the cuprous salt film described in step S1 and the fluoran dye molecular polymer described in step S2 to prepare an electrochromic device.

[0060] In some embodiments, in step S1, the method for preparing the conductive transparent electrode containing the cuprous salt film includes electro-redox method, measurement and control sputtering or vacuum evaporation, and the method is simple.

[0061] In some preferred embodiments, in step S1, the method for preparing a conductive transparent electrode containing a cuprous salt film specifically includes:

[0062] Step S11, dissolving ba...

Embodiment 1

[0090] The present embodiment provides a kind of preparation method that takes rhodamine dye molecule as the polymer of monomer, comprises the steps:

[0091] Step S21, adding 4.78g of aminorhodamine, 5.6ml of triethylamine and 40ml of redistilled dichloromethane into a 100ml round bottom flask to dissolve the aminorhodamine to form a red mixed solution;

[0092] Step S22, take 1.8mL methacryloyl chloride in the sample tube, dilute to 10mL, and slowly drop the diluted solution into the above-mentioned dichloromethane solution containing aminorhodamine and triethylamine immersed in an ice-water bath. A large amount of white mist will be generated and heat will be released. After the reaction is stable, the ice-water bath is removed and stirred at room temperature for 24 hours. After the reaction is completed, the reaction solution is concentrated and separated by column chromatography to obtain the aminorhodamine acid chloride monomer;

[0093] Step S23, dissolving 525mg of ami...

Embodiment 2

[0099] This embodiment provides a method for preparing a solid-state electrochromic device, including the following steps;

[0100] Step S1, prepare the ITO glass that contains cuprous iodide thin film, specifically comprise:

[0101] Step S11, take 22g of basic copper carbonate, 15g of disodium edetate, and 0.4g of ammonium nitrate, dissolve them in 1000mL of water at 50°C, and then use sodium hydroxide to adjust the pH value of the solution to 11-13. Get the plating solution. Subsequently, the plating solution is electrolyzed with the ITO glass as the cathode and the graphite electrode as the anode. During electrolysis, it is necessary to maintain the current density at 1-3A / dm2, and the bath temperature at 40-60°C. After electroplating for 1 second, wash off the excess plating solution on the cathode with deionized water, and dry it to obtain an ITO glass with a copper film attached, such as Figure 4 shown;

[0102] Step S12, put the above-mentioned copper-attached ITO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com