High-strength concrete for civil engineering and manufacturing method thereof

A technology of civil engineering and manufacturing method, which is applied in the field of concrete to achieve the effects of good friction resistance, changing hydrophilic properties and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

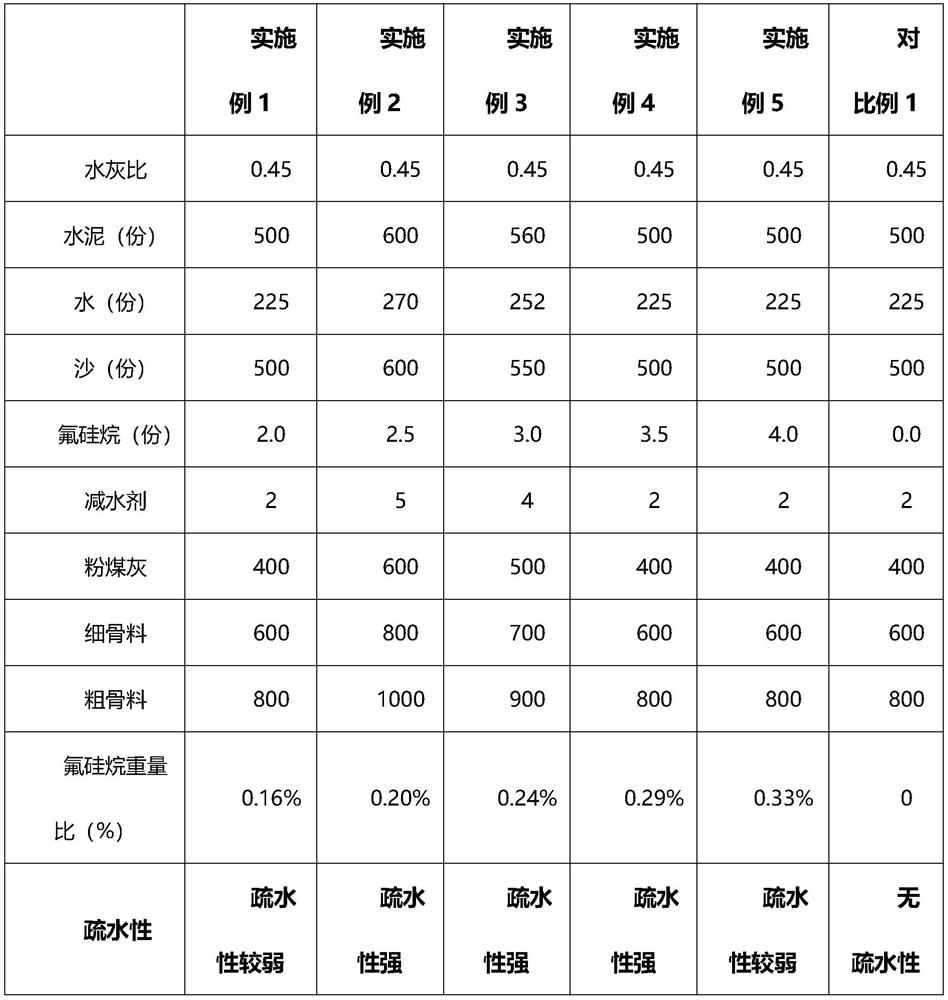

Embodiment 1

[0028] A high-strength concrete for civil engineering, including the following raw materials: 500 parts of cement, 225 parts of water, 500 parts of fine sand, 2.0 parts of fluorosilane, 2 parts of water reducing agent, 400 parts of fly ash, and 600 parts of fine aggregate parts, 800 parts of coarse aggregate.

[0029] A method for making high-strength concrete for civil engineering: comprising the steps of:

[0030] S1. Weigh 500 parts of P.O42.5 ordinary Portland concrete and 500 parts of fine sand screened through a 60-mesh fine sieve, and mix them uniformly in the container, then add 225 parts of tap water for mixing in the container, and then Stir it evenly to form concrete slurry, then add 2 parts of water reducer, 400 parts of fly ash, 600 parts of fine aggregate, and 800 parts of coarse aggregate to the concrete slurry, and stir it evenly;

[0031] S2. Add fluorosilane to the concrete slurry and place it under a vertical mixer for stirring, the stirring speed is 250r / m...

Embodiment 2

[0034] The difference between Example 2 and Example 1 is that the weight fractions of each component are different, 600 parts of cement, 270 parts of water, 600 parts of fine sand, 2.5 parts of fluorosilane, 5 parts of water reducing agent, 600 parts of fly ash, 800 parts of fine aggregate and 1000 parts of coarse aggregate.

Embodiment 3

[0036] The difference between Example 3 and Example 1 is that each component is added in different weight fractions, 560 parts of cement, 252 parts of water, 560 parts of fine sand, 3 parts of fluorosilane, 4 parts of water reducer, 500 parts of fly ash, 700 parts of fine aggregate and 900 parts of coarse aggregate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com