Waterborne polyurethane-silica sol antifogging coating and preparation method and application thereof

A water-based polyurethane and anti-fog coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of weak bonding, poor durability, instability, etc., and achieve improved transparency, low VOC content, and increased use time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

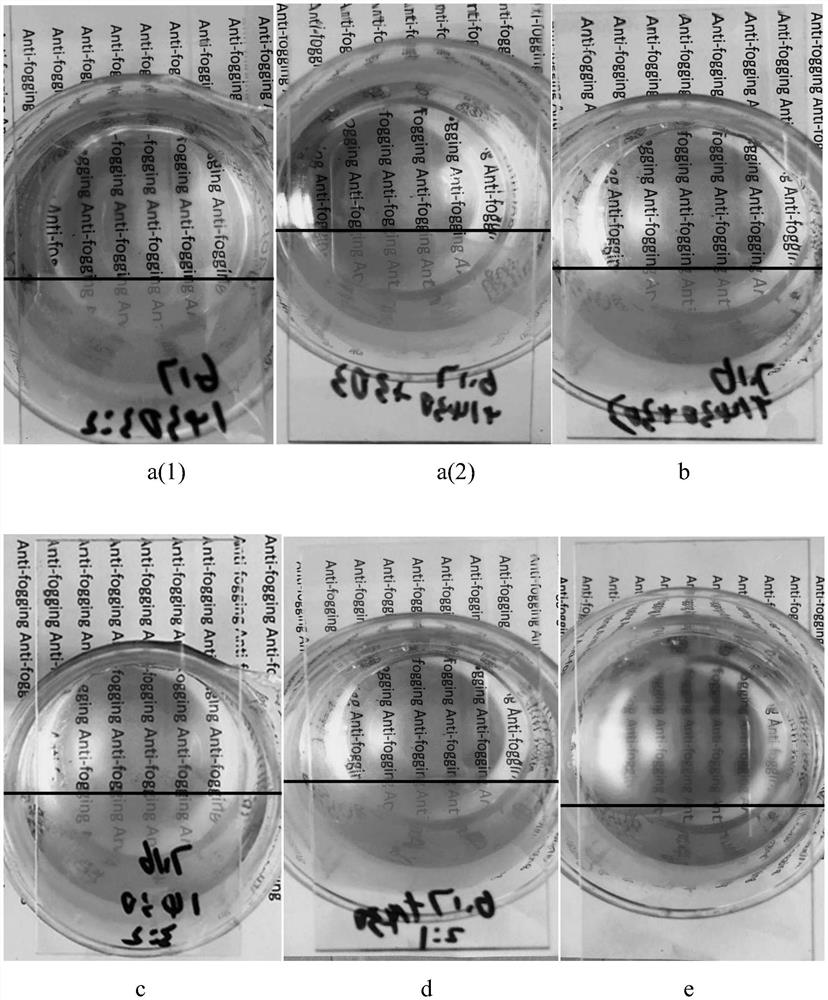

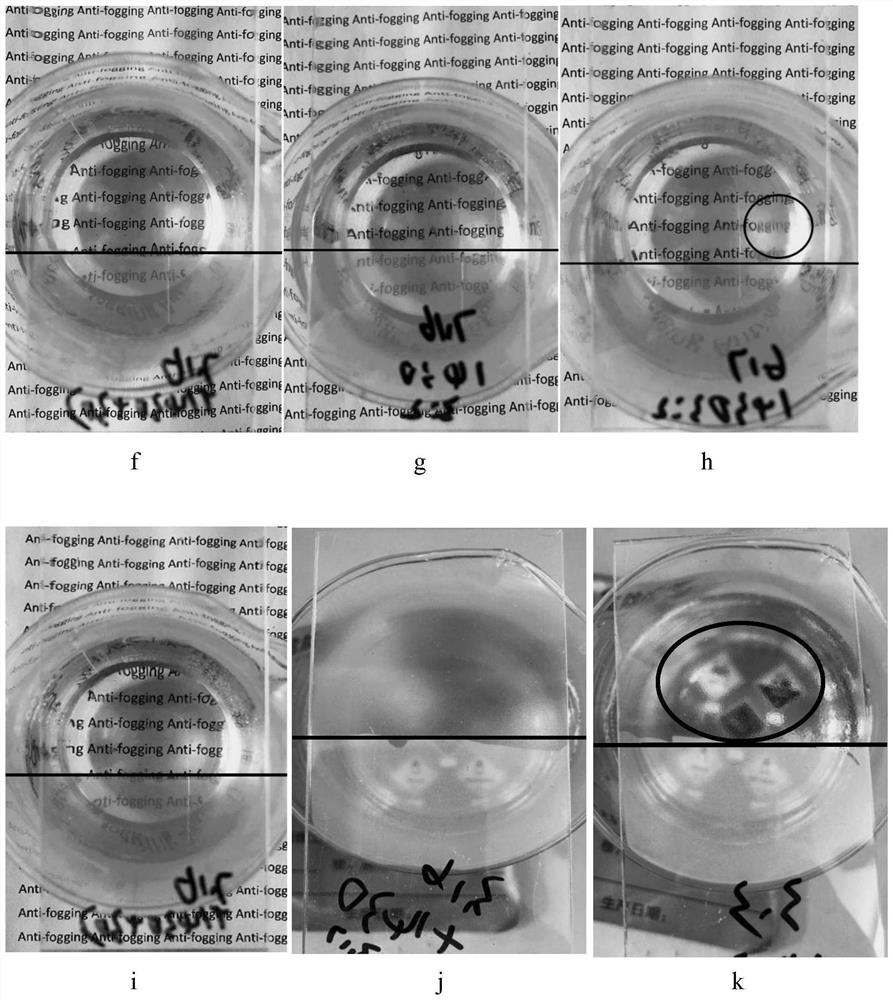

Image

Examples

Embodiment 1

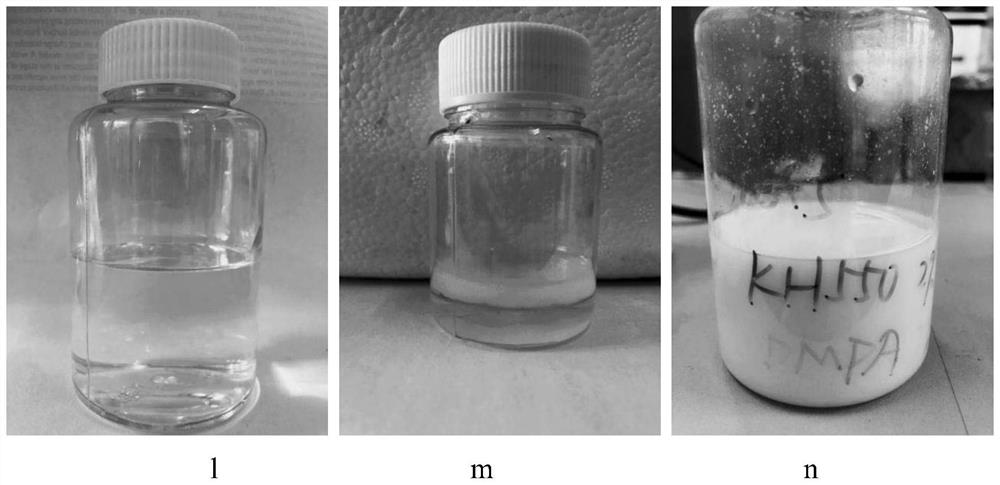

[0046] (1) 8.33 g of IPDI is added to 14.4 g of PPG-2000 and 3.6 g of PEG-400, a stirrer, a thermometer, and a condensed tube, and stirred to 80 ° C, and February Dibutyltin catalyst, reaction 2H, then add 0.18 g of TMP and 1.35 g of dihydroxymethropion acid at the same temperature, reacted for 1 h and 2h, respectively; temperature above 90 ° C, 2.48 g of pentaerythritol is added, and 2.5 h, The terminal hydroxy polyurethane prepolymer was obtained; the viscosity of the system was added to acetone.

[0047] (2) The system temperature was reduced to 65 ° C, and 1.68 g IPTES was added, and the reaction was reacted for 3 h, and the terminal hydroxyl silicone-polyurethane prepolymer was obtained.

[0048] (3) The system was cooled to 45 ° C, and 1.02 g of triethylamine was added, and the reaction was 30 min; poured into the polyurethane prepolymer described above into the dispersion bucket, and then 64.5 g of deionized water at high speed. The slowly poured, was subjected to dispersio...

Embodiment 2

[0052] As compared with Example 1, an aqueous polyurethane emulsion-silica sol composite coating was prepared, and the first type of polyol added in step (1), the second type of polyol, respectively Changed to 14.4 g of PCL-2000 and 3.6 g of PEG-600, the rest of the other.

Embodiment 3

[0054] As compared with Example 1, an aqueous polyurethane emulsion-silica sol composite coating was prepared, and the first type of polyol solution in step (1) was changed to 14.4 g of PHA-2000. Exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com