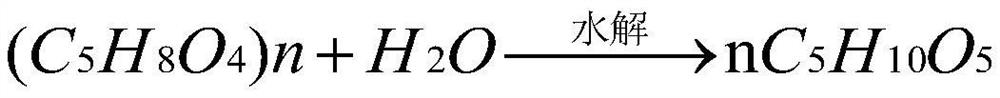

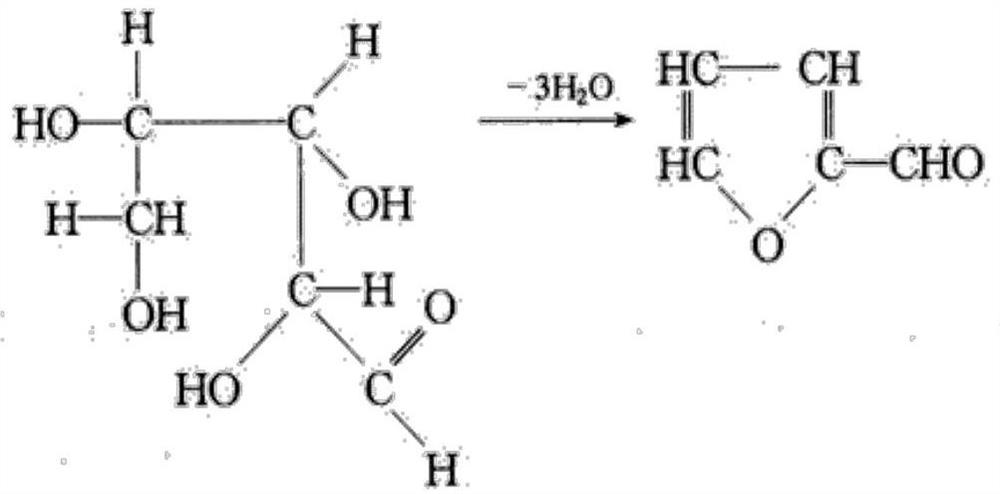

Furfural hydrolysis method

A furfural and hydrolysis reaction technology, applied in the direction of organic chemistry, etc., can solve the problems of large consumption of extractant, low reactor efficiency, increased production cost, etc., and achieve the effects of reducing steam consumption, improving furfural yield and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for furfural hydrolysis, comprising the following steps:

[0032] S1: After fully mixing the screened and pulverized corncobs with 3% dilute sulfuric acid at a ratio of 4:1, put them into the reaction container;

[0033] S2: Introduce steam at 170°C from the bottom of the reaction vessel in S1 for hydrolysis, and control the steam pressure at 0.8-2.5Mpa;

[0034] S3: adding a certain amount of polymerization inhibitor thiourea, wherein the proportion of polymerization inhibitor thiourea accounts for 0.3% of the mass of corn cob, and after hydrolysis reaction for 100 minutes, the generated water vapor mixture is condensed to obtain furfural stock solution;

[0035] The content of the furfural stock solution obtained after analysis was 4.5%.

Embodiment 2

[0037] A method for furfural hydrolysis, comprising the following steps:

[0038] S1: After fully mixing the screened and pulverized corncobs with 4% dilute sulfuric acid at a ratio of 6:1, put them into the reaction container;

[0039] S2: Introduce steam at 175°C from the bottom of the reaction vessel in S1 for hydrolysis, and control the steam pressure at 0.8-2.5Mpa;

[0040] S3: adding a certain amount of polymerization inhibitor thiourea, wherein the proportion of polymerization inhibitor thiourea accounts for 0.1% of the mass of corncob, after hydrolysis reaction for 110 minutes, the generated water vapor mixture is condensed to obtain furfural stock solution;

[0041] The content of the furfural stock solution obtained after analysis is 5%.

Embodiment 3

[0043] A method for furfural hydrolysis, comprising the following steps:

[0044] S1: After fully mixing the screened and pulverized corncobs with 5% dilute sulfuric acid at a ratio of 8:1, put them into the reaction container;

[0045] S2: Introduce steam at 185°C from the bottom of the reaction vessel in S1 for hydrolysis, and control the steam pressure at 0.8-2.5Mpa;

[0046] S3: adding a certain amount of polymerization inhibitor thiourea, wherein the proportion of polymerization inhibitor thiourea accounts for 0.2% of the mass of corncob, after hydrolysis reaction for 120 minutes, the generated water vapor mixture is condensed to obtain furfural stock solution;

[0047] The content of the obtained furfural stock solution after analysis is 9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com