Deuterium-depleted wastewater recycling device and method

A technology of wastewater recycling and deuterium-depleted water, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems such as water resource waste, save water, improve deuterium value instability, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

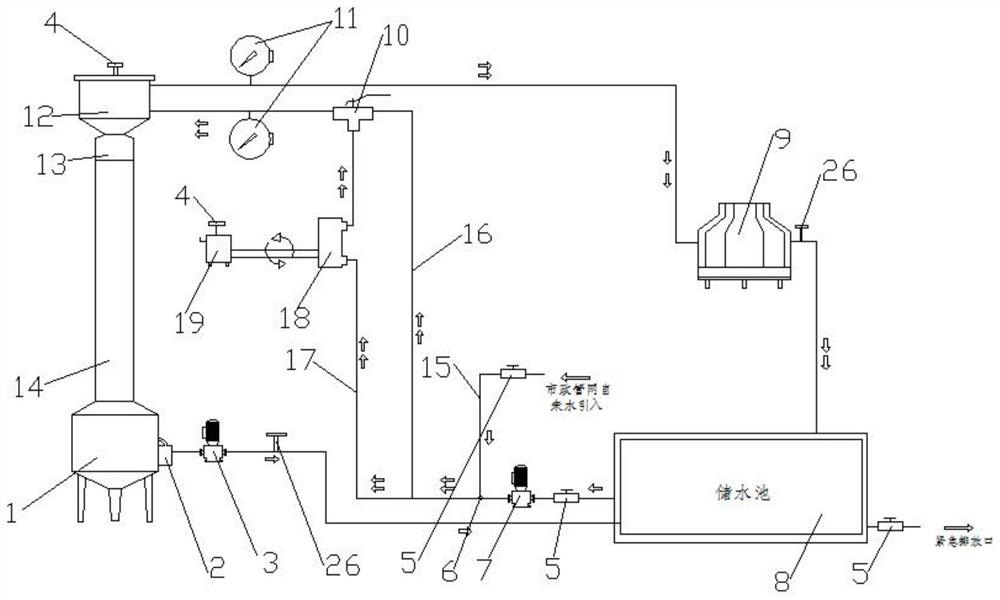

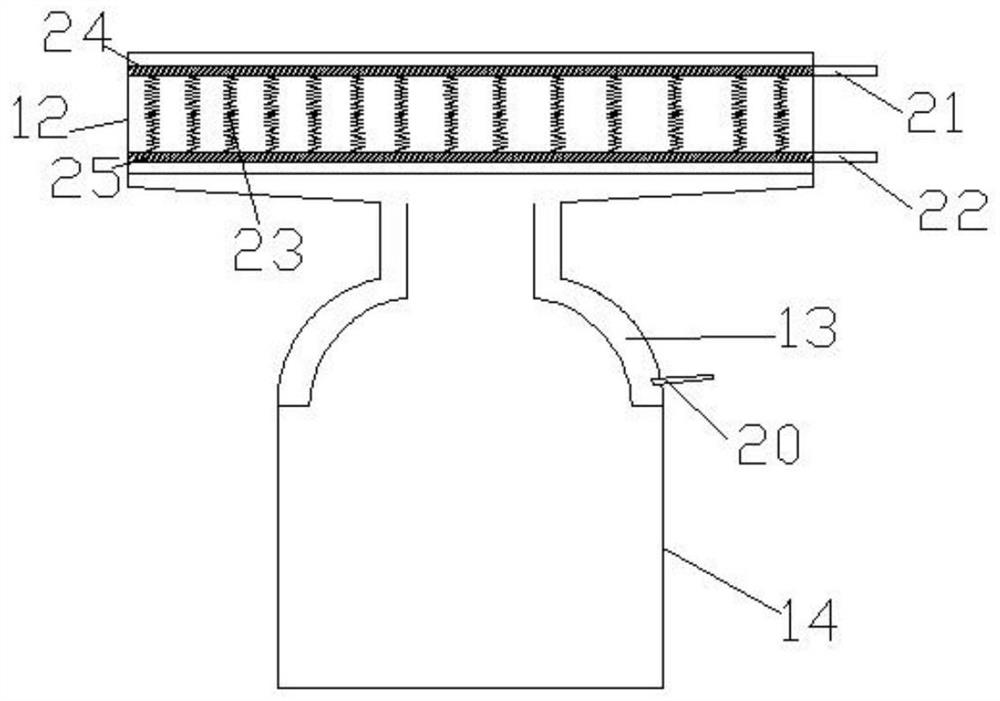

[0044] The waste water in the production process of deuterium-depleted water enters the water storage tank 8 through the diaphragm vacuum pump 3 and the pipeline to cool down and naturally cools to the ambient temperature of 20-28°C, and the cooled waste water is transported to the deuterium-depleted water condensation chamber 12 through the pipeline centrifugal pump 7 Use as condensate. The used high-temperature condensed water passes through the cooling tower 9 to dissipate heat to below 35°C and then flows back into the water storage tank 8, thereby realizing zero discharge and recycling of deuterium-depleted wastewater. Municipal pipe network water is used as supplementary water for storage tank 8 . After the water volume of the water storage tank 8 reaches the specified water level, close the municipal pipe network water supply valve 5, open the pipeline centrifugal pump 7 and the valve 5, and use the water source in the water storage tank 8 to supply condensed water to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com