Method for preparing composite regenerated foam material by using waste EVA-based material

A technology of composite regeneration and foam materials, applied in recycling technology, plastic recycling, etc., can solve problems such as economic shocks, achieve easy operation, reduce material costs, and achieve better performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In this embodiment, a method for preparing a composite recycled foam material by using waste EVA-based materials mainly includes the following steps in parts by weight:

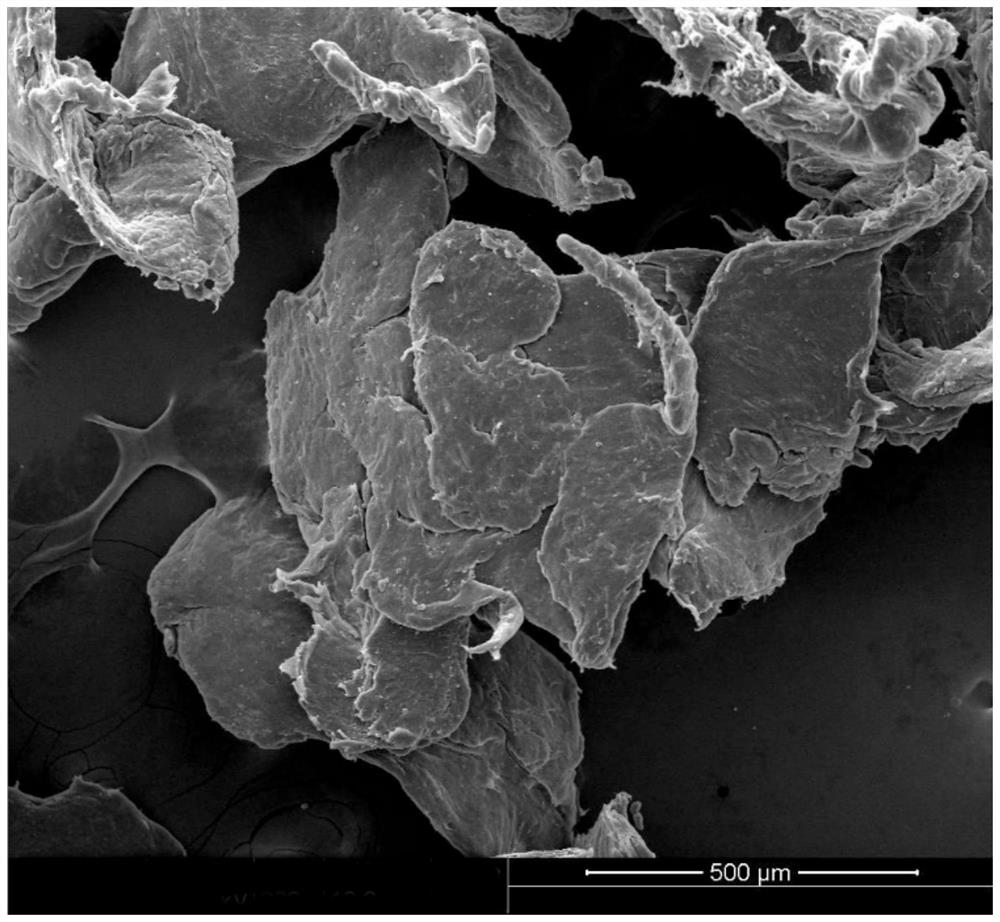

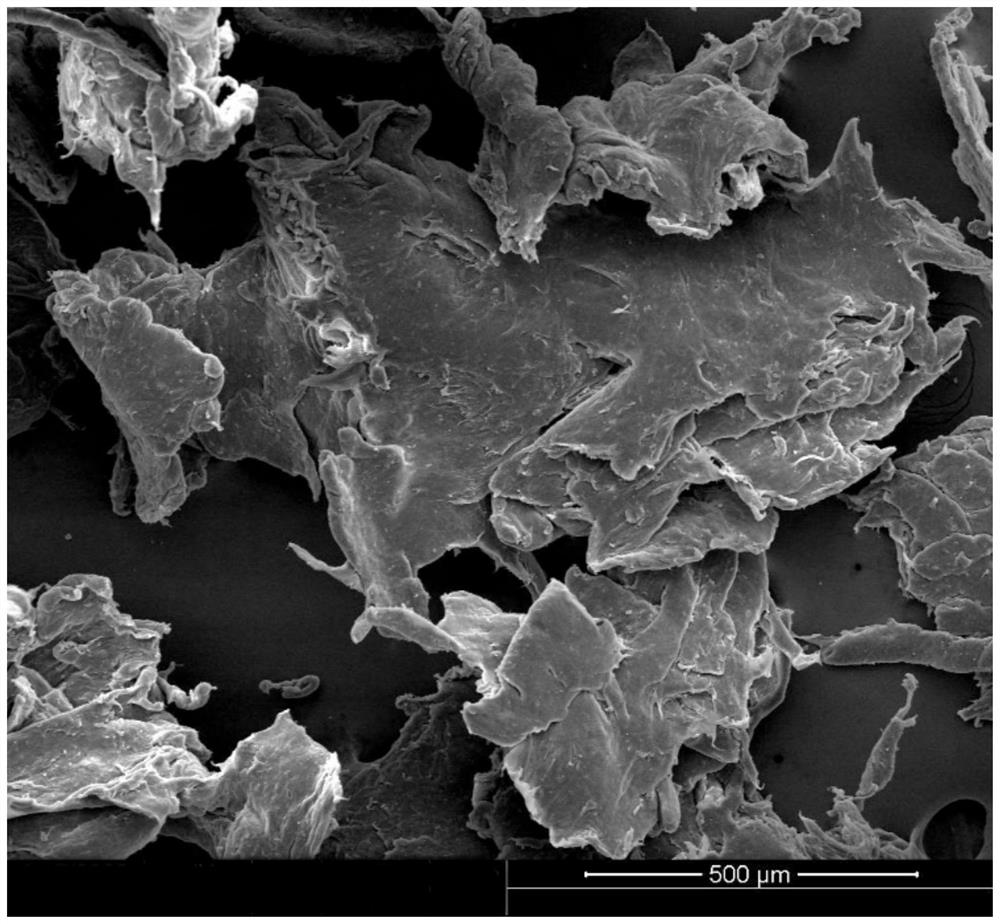

[0068] (1) After the waste EVA-based shoe sole foam products are pretreated by cleaning, they are processed and coarsely crushed to waste EVA-based materials with a particle size of 10-20 mm;

[0069] (2) Put the waste EVA-based material into a disc-shaped solid-phase mechanochemical reactor for grinding and pulverization. After the grinding is completed, collect the waste EVA-based ultrafine flake powder; wherein, the disc-shaped solid-phase mechanochemical reactor The process parameters are as follows: the grinding pressure is 0.5MPa, the grinding surface temperature of the grinding disc is controlled by feeding a constant temperature circulating liquid medium with a temperature of -16°C, 12 cycles of grinding, and the grinding disc rotates at 45 rpm;

[0070] (3) Put 20 parts of waste EVA-based ultr...

Embodiment 2

[0074] In this embodiment, a method for preparing a composite recycled foam material by using waste EVA-based materials mainly includes the following steps in parts by weight:

[0075] (1) After the waste EVA-based shoe sole foam products are pretreated by cleaning, they are processed and coarsely crushed to waste EVA-based materials with a particle size of 10-20 mm;

[0076] (2) Put the waste EVA-based material into a disc-shaped solid-phase mechanochemical reactor for grinding and pulverization. After the grinding is completed, collect the waste EVA-based ultrafine flake powder; wherein, the disc-shaped solid-phase mechanochemical reactor The process parameters are as follows: the grinding pressure is 0.4MPa, the grinding surface temperature of the grinding disc is controlled by feeding a constant temperature circulating liquid medium with a temperature of -14°C, 10 cycles of grinding, and the grinding disc rotates at a speed of 45 rpm;

[0077] (3) Put 20 parts of waste EVA...

Embodiment 3

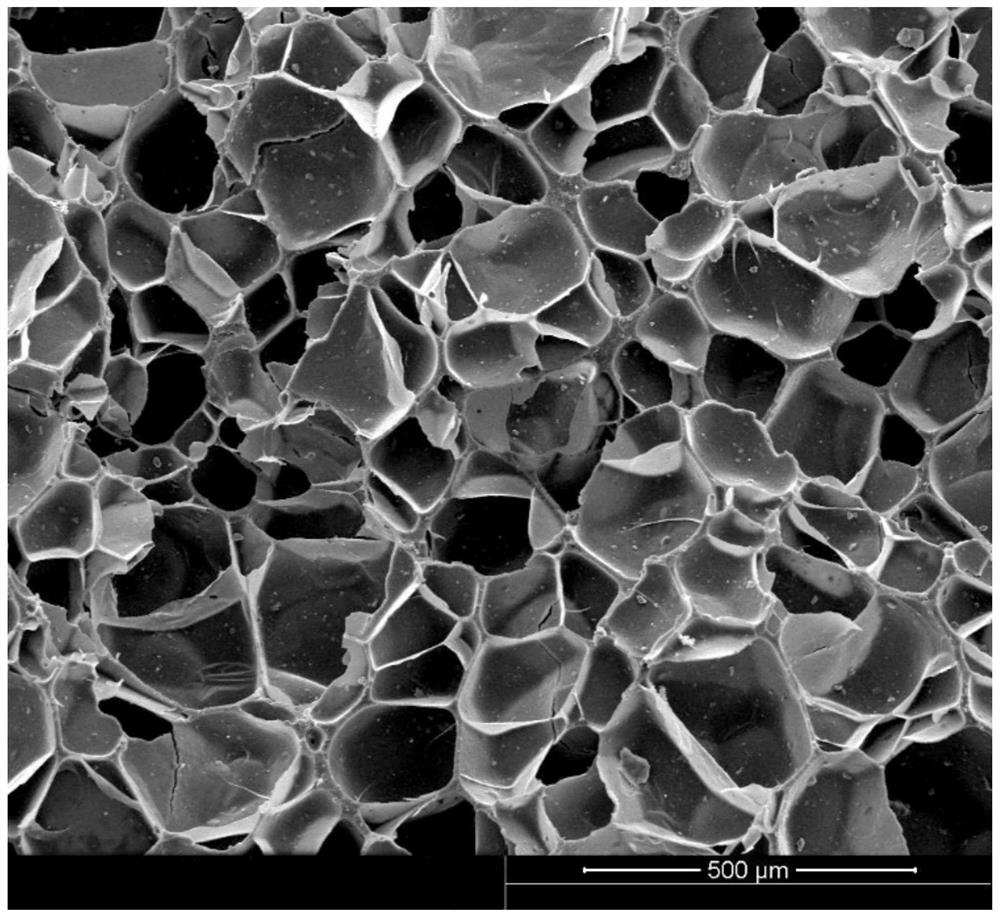

[0116] In this embodiment, a method for preparing a composite recycled foam material by using waste EVA-based materials mainly includes the following steps in parts by weight:

[0117] (1) After the waste EVA-based shoe sole foam products are pretreated by cleaning, they are processed and coarsely crushed to waste EVA-based materials with a particle size of 10-20 mm;

[0118] (2) Put the waste EVA-based material into a disc-shaped solid-phase mechanochemical reactor for grinding and pulverization. After the grinding is completed, collect the waste EVA-based ultrafine flake powder; wherein, the disc-shaped solid-phase mechanochemical reactor The process parameters are as follows: the grinding pressure is 0.8MPa, the temperature of the grinding surface of the grinding disc is controlled by feeding a constant temperature circulating liquid medium with a temperature of -10°C, 10 cycles of grinding, and the grinding disc rotates at a speed of 50 rpm;

[0119] (3) Put 22 parts of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com