Flue gas denitration device for petrochemical industry and use method thereof

A flue gas and denitrification technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of short service life of catalysts, high operating costs, and failure to meet emission standards, so as to improve mixing uniformity, The effect of improving the temperature balance and reducing the cost of denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0050] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0051] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

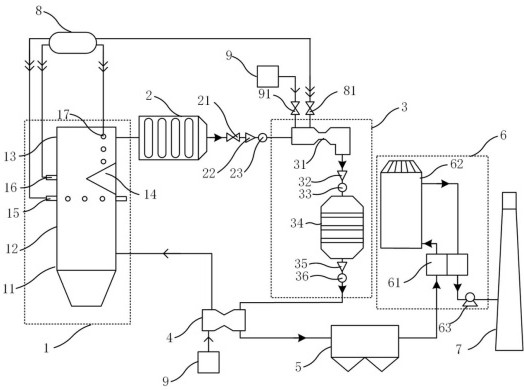

[0053] combined with figure 1 In this embodiment, a petrochemical industry flue gas denitrification device is provided, including SNCR reaction unit 1, waste heat boiler 2, SCR reaction unit 3, air preheater 4, electrostatic precipitator 5, and desulfurization unit sequentially connected along the flue gas direction 6 and a chimney 7; the SNCR reaction unit 1 includes a boiler 11 and a spray gun arranged on the boiler 11, and the spray gun communicates with the ammonia gas source 8 and the air source 9 respectively, and the SCR reaction unit 3 includes a boiler located on the flue The mixing device 31 in the horizontal section and the SCR reactor 34 located in the vertical section of the flue, the SCR reactor 34 is filled with a molecular sieve catalyst with double active centers, and the mixing device 31 communicates with the ammonia gas source 8 and the air source respectively 9. The desulfurization unit 6 includes a desulfurization tower 62 .

[0054] In the above technica...

Embodiment 2

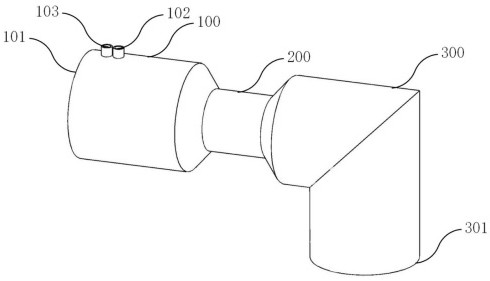

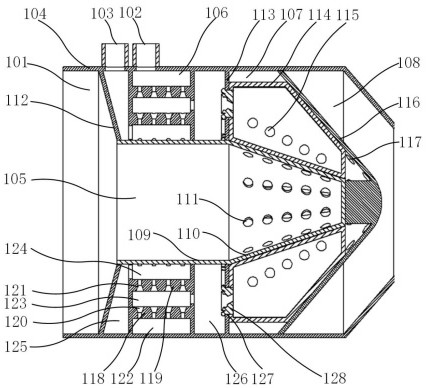

[0060] combined with Figures 2 to 6 , the present embodiment provides a mixing device 31 used in Embodiment 1, the mixing device 31 includes a mixing pipe section 100, a thin diameter pipe section 200 and a diversion pipe section 300 connected in sequence, and flue gas and diluted ammonia gas are mixed in the mixing pipe section After mixing in 100, it is homogenized in the narrow-diameter pipe section 200, and then flows out after being vertically guided by the guide pipe section 300.

[0061] The specific structure is as figure 2 As shown, the mixing tube section 100 and the thin-diameter tube section 200 are horizontal tubes, the mixing tube section 100 is horizontally provided with a flue gas inlet 101, and is vertically provided with an ammonia gas inlet 102 and an air inlet 103, and the mixing tube section 100 The tail is tapered and connected to the thin-diameter pipe section 200, the diversion pipe section 300 is a right-angle pipe, the horizontal end of which is ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com