Preparation method and application of flower-like structure CuO-In2O3 composite material

A cuo-in2o3, composite material technology, applied in gallium/indium/thallium compounds, analytical materials, material resistance, etc., to achieve high sensitivity, simple manufacturing process, and good crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Flower-like structure CuO-In 2 o 3 Composite material preparation method, comprises the following steps:

[0036] Step 1: Dissolve a certain amount of indium chloride and copper nitrate in a mixed solution prepared by 20 mL of absolute ethanol and 60 mL of distilled water, stir with a magnetic stirrer for 30 minutes at 40°C, and then add twelve Alkyl sodium sulfate and urea, continue to fully stir for 30 minutes, and prepare a hydrothermal synthesis precursor reaction solution;

[0037] Step 2: Transfer the precursor reaction solution prepared in Step 1 into a polytetrafluoroethylene-lined stainless steel autoclave with a filling degree of 80%, and seal it. The temperature was kept at 160° C. for 5 hours, and then cooled to room temperature with the furnace to obtain the reaction product.

[0038] Step 3: The reaction product obtained in Step 2 is centrifuged, washed repeatedly with distilled water and absolute ethanol, and then dried.

[0039] Step 4: Put the dried...

Embodiment 1

[0046] (1) Preparation of flower-like structure In 2 o 3 Material

[0047] Step 1: Dissolve 0.293 g of indium chloride in a mixed solution prepared by 20 mL of absolute ethanol and 60 mL of distilled water, stir with a magnetic stirrer for 30 minutes at 40°C, and then add 0.519 g of sodium lauryl sulfate to the above solution and 2.102g of urea, and continued to fully stir for 30 minutes to prepare a hydrothermal synthesis precursor reaction solution.

[0048] Step 2: Transfer the precursor reaction solution prepared in Step 1 into a 100 ml polytetrafluoroethylene-lined stainless steel autoclave with a filling degree of 80%, and seal it.

[0049] Step 3: Put the reactor in step 2 in an oven, keep it warm at 160° C. for 5 hours, and then cool it down to room temperature.

[0050] Step 4: Centrifuge the reactant solution prepared in Step 3 to obtain a white precipitate, which is then repeatedly washed with distilled water and absolute ethanol.

[0051] Step 5: Place the prod...

Embodiment 2

[0057] (1) Preparation of flower-like structure CuO-In 2 o 3 composite material

[0058] Step 1: Dissolve 0.293 g of indium chloride and 0.0072 g of copper nitrate in a mixed solution prepared by 20 mL of absolute ethanol and 60 mL of distilled water. After stirring with a magnetic stirrer for 30 minutes at 40°C, add 0.519 g of ten Sodium dialkylsulfate and 2.102 g urea were continuously stirred for 30 minutes to prepare a hydrothermal synthesis precursor reaction solution.

[0059] Steps 2, 3, 4, 5 and 6 are the same as in Example 1.

[0060] (2) Flower-like structure CuO-In 2 o 3 Structural Characterization of Composite Materials

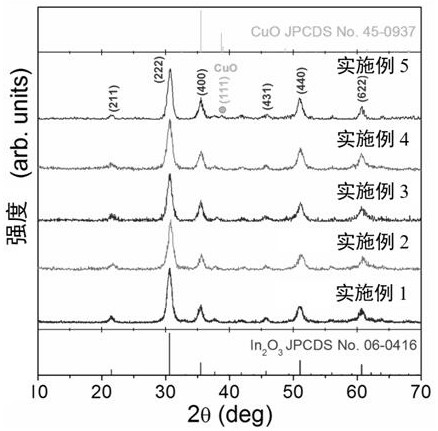

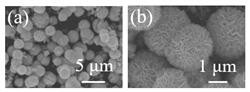

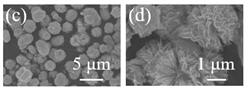

[0061] The crystal structure of the product was characterized by XRD powder diffractometer (XRD, PANalytical X’Pert Pro). from figure 1 It can be seen that in the sample except the cubic phase In 2 o 3 Except for the peak of CuO, no diffraction peak of CuO appears. All diffraction characteristic peaks are very sharp, and no other impurit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com