Production process of polyester fabric capable of resisting ultraviolet rays

A production process and ultraviolet technology, which is applied in the field of polyester fabrics, can solve the problems of ground pollution, increase the humidity of the constant temperature room, and slow drying efficiency, and achieve the effects of preventing humidity from rising, improving drying efficiency, and reducing the possibility of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] A production process for polyester fabrics capable of carrying ultraviolet rays, comprising the following steps:

[0047] S1, first process and produce common polyester fabric;

[0048] S2. Dilute the nano-fabric anti-ultraviolet and antibacterial finishing agent with pure influent water at a ratio of 1:15 to obtain a diluted solution of the nano-fabric anti-ultraviolet and antibacterial finishing agent;

[0049] S3, process and produce the common polyester fabric and soak it in the nano-fabric anti-ultraviolet and antibacterial finishing agent dilution solution for 1 hour;

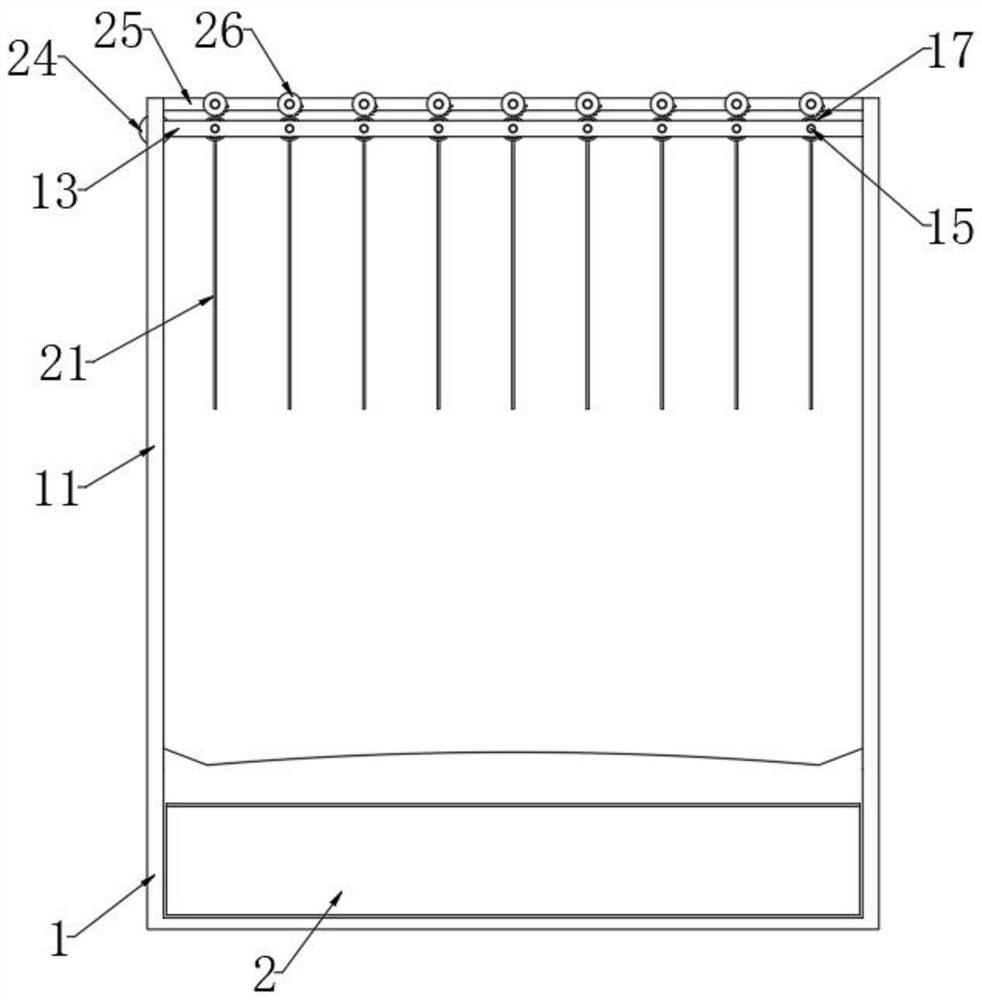

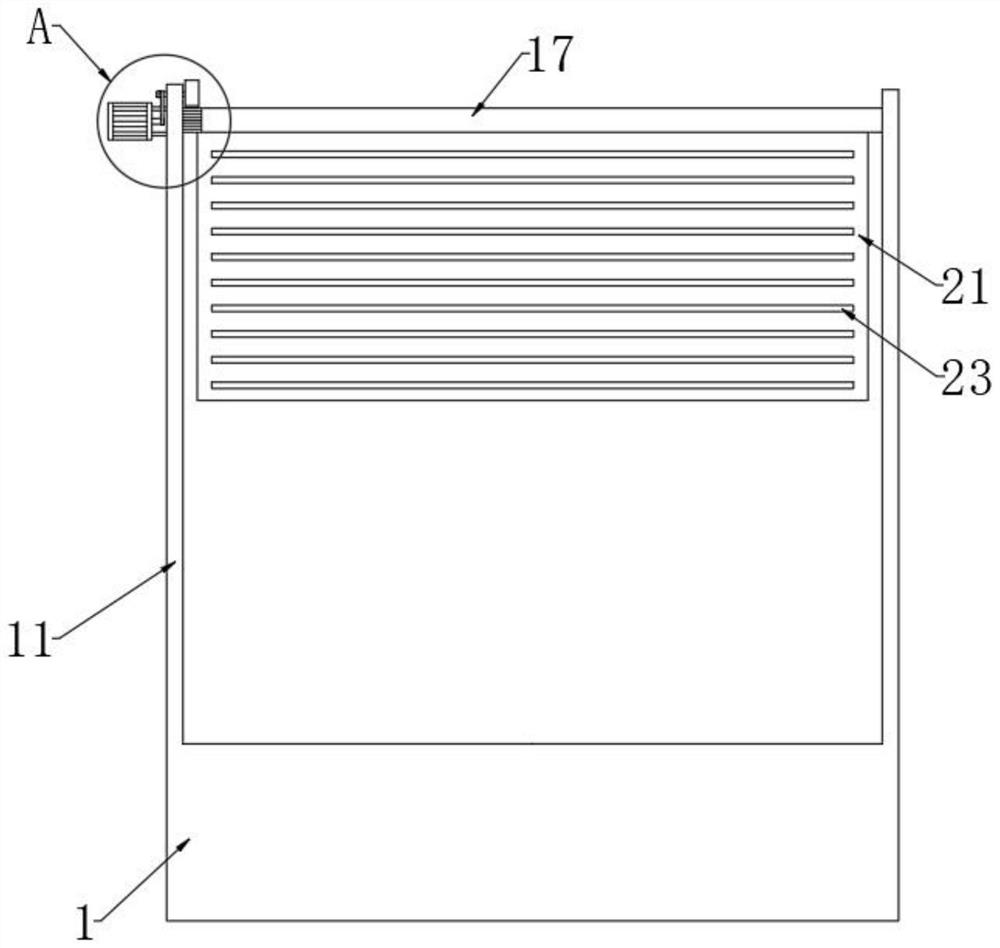

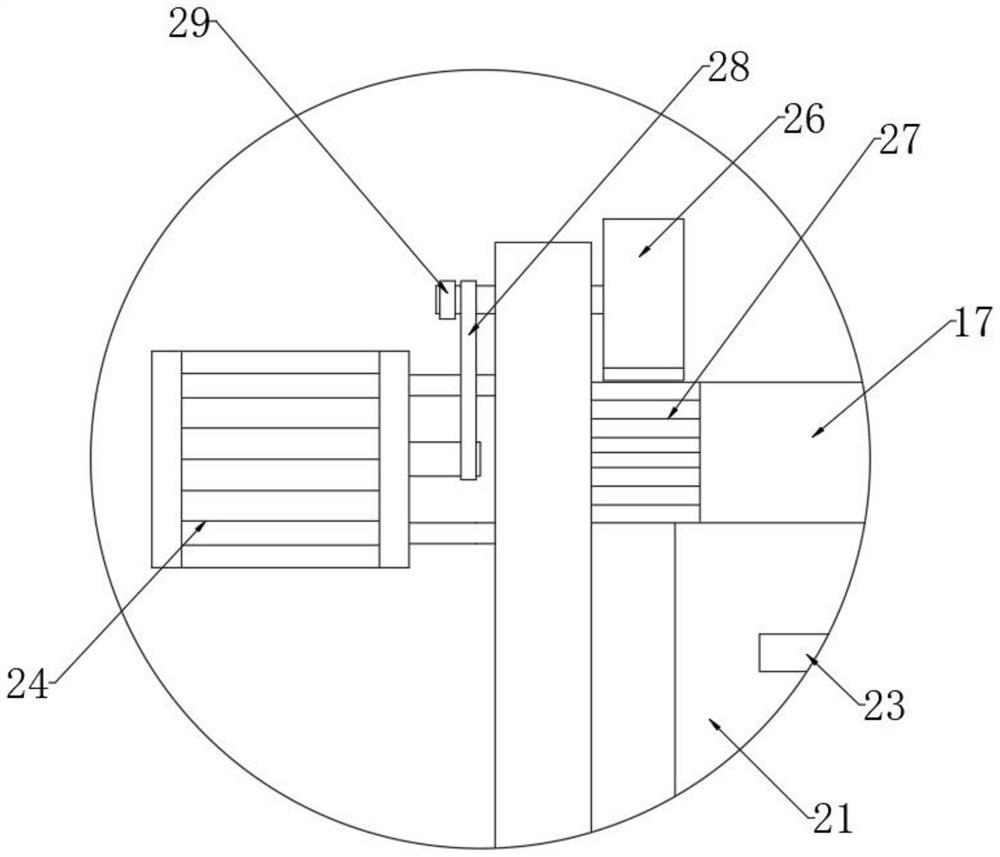

[0050] S4. Hang the soaked ultraviolet-carrying polyester fabric on a drying device and push it into a constant temperature room, and dry the soaked ultraviolet-carrying polyester fabric to finally obtain a finished ultraviolet-carrying polyester fabric.

[0051] see figure 1 and 4 , the drying device in S4 includes a base 1, the inner cavity of the base 1 is embedded with a reaction box 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com