Industrial green production process of coriolus versicolor glycopeptide

A green production, Yunzhi glycopeptide technology, applied in the fields of peptides, microorganisms, organic chemistry, etc., can solve the problems of high production cost of fermentation mycelium, unresolved large amount of emissions, etc., to achieve comprehensive utilization of resources and increase product output ratio, the effect of maintaining productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

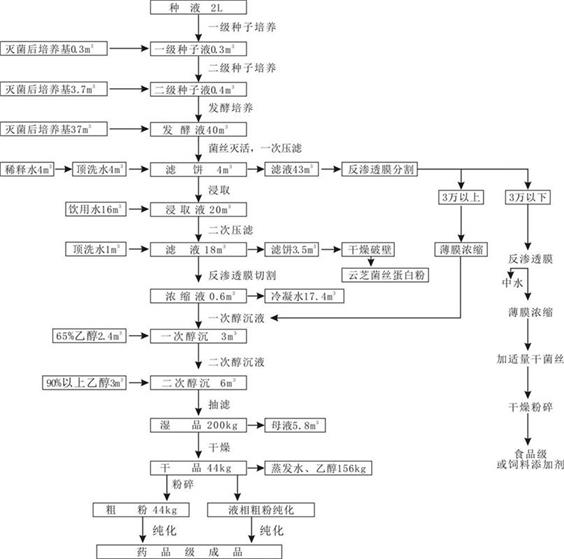

[0027] The present invention will be further described by taking the 50T fermenting tank as an example below.

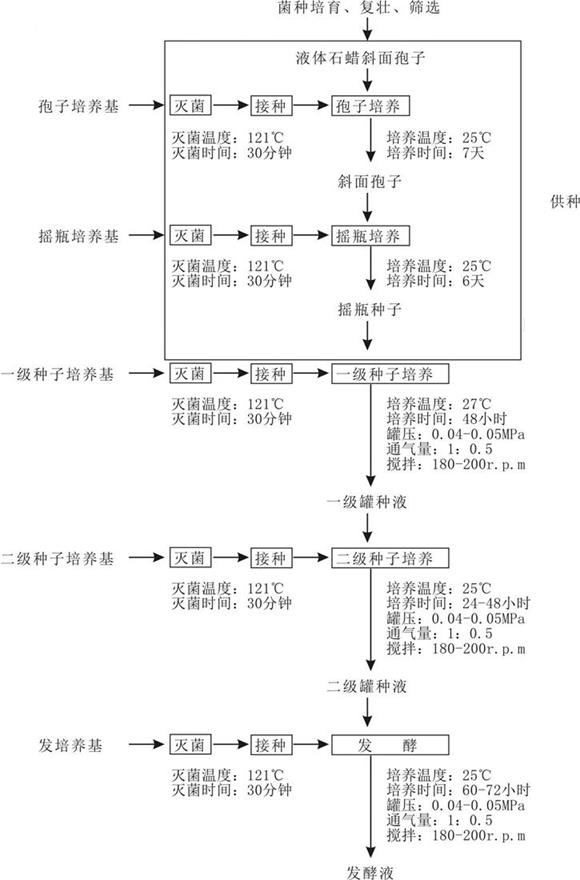

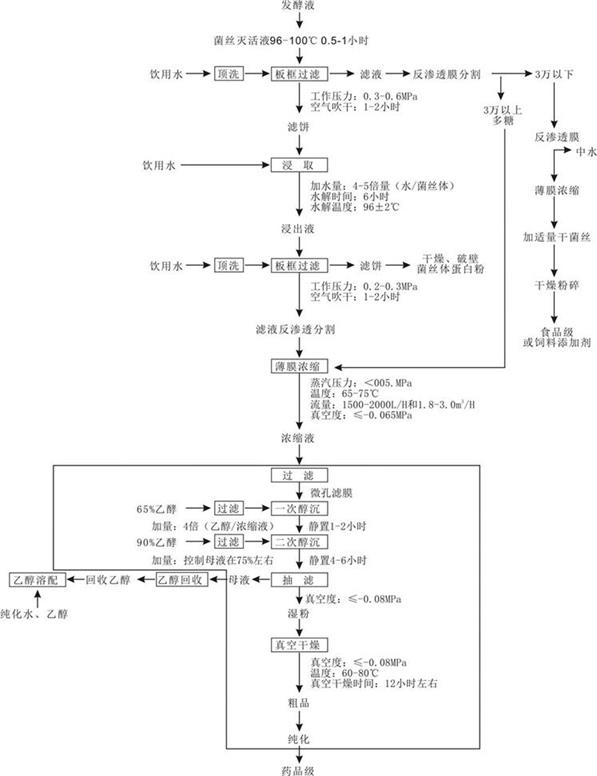

[0028] Referring to the accompanying drawings, an industrialized green production process of Yunzhi glycopeptide is characterized in that it comprises the following steps:

[0029] (1) Strain screening: COV-1 versicolor versicolor strain was used as the starting strain, non-transgenic technology was adopted, and according to the principle that the large temperature difference of solid fermentation is easy to produce variable fruiting bodies, it was subjected to protoplast mutagenesis to simulate the harsh natural environment, Select vigorous strains with strong vitality for rejuvenation. The strain screening method is the low temperature freezing recovery method, which specifically includes the following steps:

[0030] a. Strain activation and purification and rejuvenation: activate the preserved strains in advance, make plate A, the medium is a comprehensive mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com