Method for preparing high-purity boehmite by dry method and high-purity boehmite

A boehmite, high-purity technology, applied in chemical instruments and methods, alumina/hydroxide preparation, inorganic chemistry, etc., can solve the problems of high residual metal impurities, lower boehmite purity, and more washing wastewater , to achieve the effect of reducing operating costs, improving product purity, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The dry method described in the present embodiment prepares the method for high-purity boehmite, comprises the following steps:

[0049] S1. Mix 350g of aluminum hydroxide, 50g of gamma-alumina, and 20g of aluminum chloride hexahydrate uniformly with a particle size of 5 μm;

[0050] S2. Put the mixture obtained in step S1 into a 1L autoclave, heat up to 250°C at 4°C / min, and then keep the temperature for 48 hours. After the reaction, cool down, then filter and separate, wash the filter cake with deionized water, and put it in an oven Dry at 150°C to obtain high-purity granular boehmite.

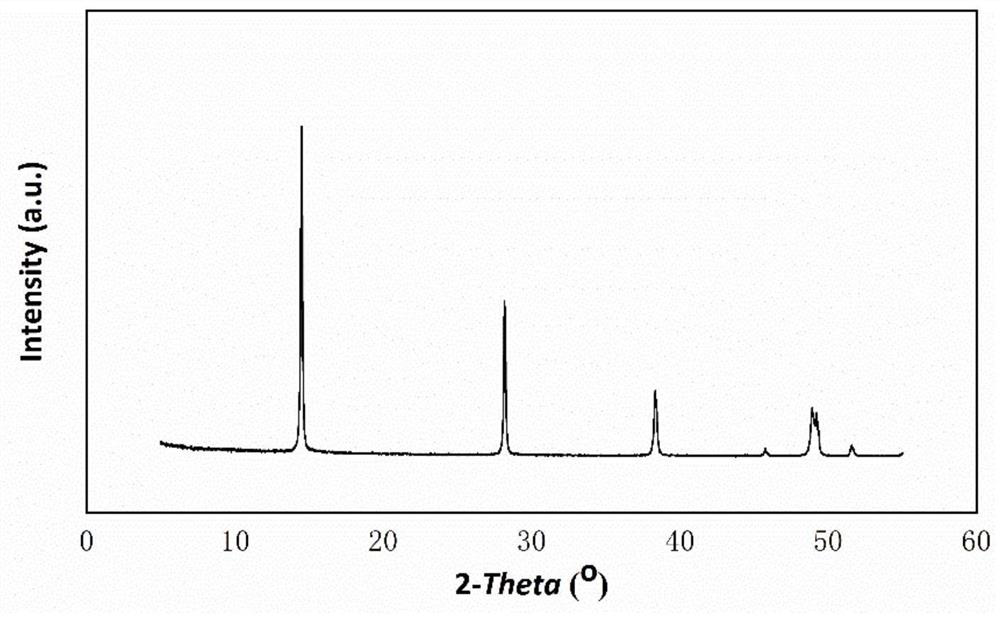

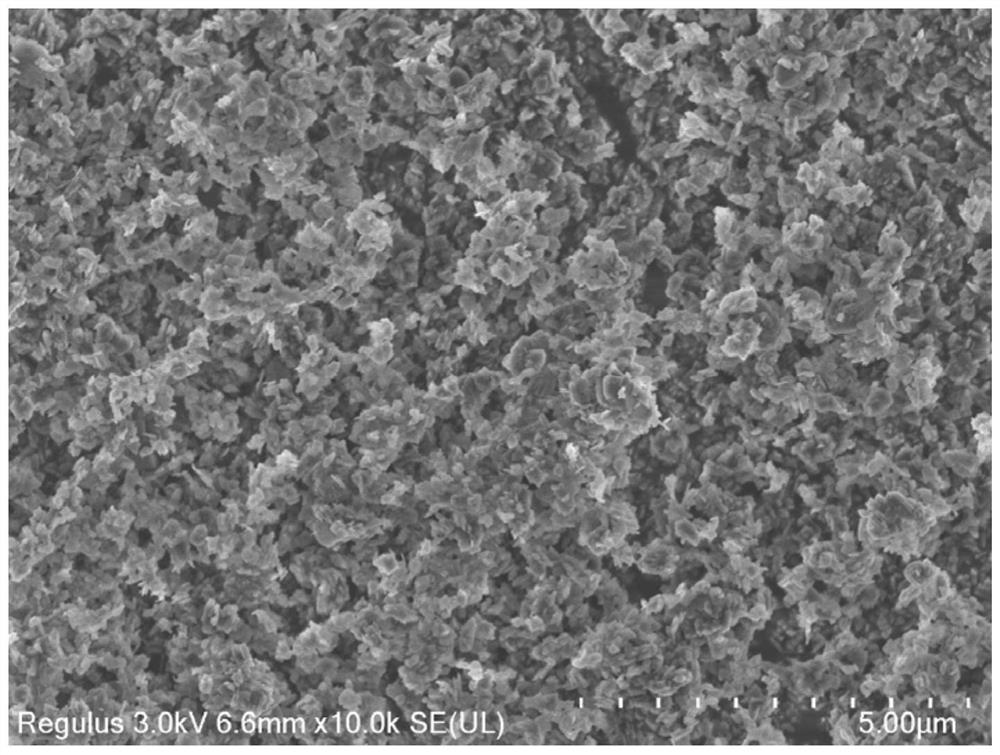

[0051] Such as figure 1 Shown is the XRD figure of the high-purity granular boehmite that the present embodiment obtains; figure 2 Shown is the SEM picture of the high-purity granular boehmite obtained in this example.

Embodiment 2

[0053] The dry method described in the present embodiment prepares the method for high-purity boehmite, comprises the following steps:

[0054] S1. Mix 380g pseudo-boehmite, 20g fast powder removal, 20g aluminum nitrate nonahydrate, and 20g water; the water content is 4.55wt%;

[0055] S2. Put the mixture obtained in step S1 into a 1L autoclave, raise the temperature to 200°C at 5°C / min, and then keep the temperature for 24 hours. After the reaction, cool down, then filter and separate, wash the filter cake with deionized water, and put it in an oven Dry at 130°C to obtain high-purity parallelepiped boehmite.

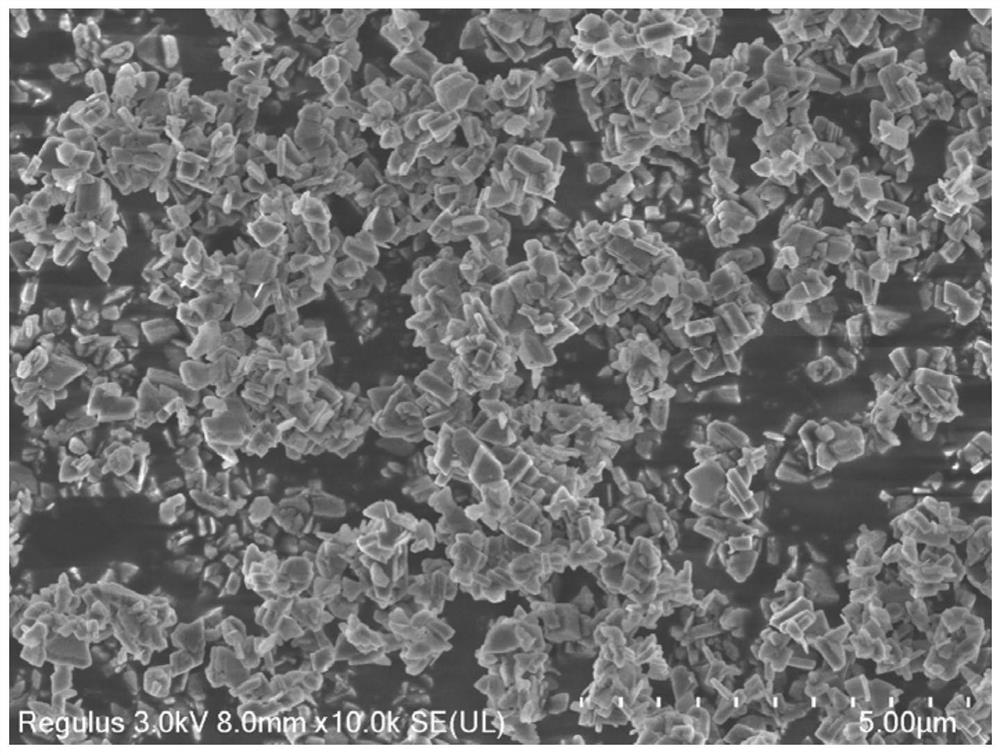

[0056] Such as image 3 Shown is the SEM image of the high-purity parallelepiped boehmite obtained in this example.

Embodiment 3

[0058] The dry method described in the present embodiment prepares the method for high-purity boehmite, comprises the following steps:

[0059] S1. Mix 380g of aluminum hydroxide with a particle size of 5 μm, 20g of quick-release powder, 20g of aluminum isopropoxide, and 30g of water; the water content is 6.67wt%;

[0060] S2. Put the mixture obtained in step S1 into a 1L autoclave, heat up to 220°C at 6°C / min, and then keep the temperature for 32 hours. After the reaction, cool down, then filter and separate, wash the filter cake with deionized water, and put it in an oven Dry at 120°C to obtain high-purity flaky boehmite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com