Endless rope speed regulation mechanical winch driving device used for mine

A technology of mechanical winches and driving devices, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of high labor intensity, difficult installation, high noise, etc., reduce labor intensity, easy to understand operation, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

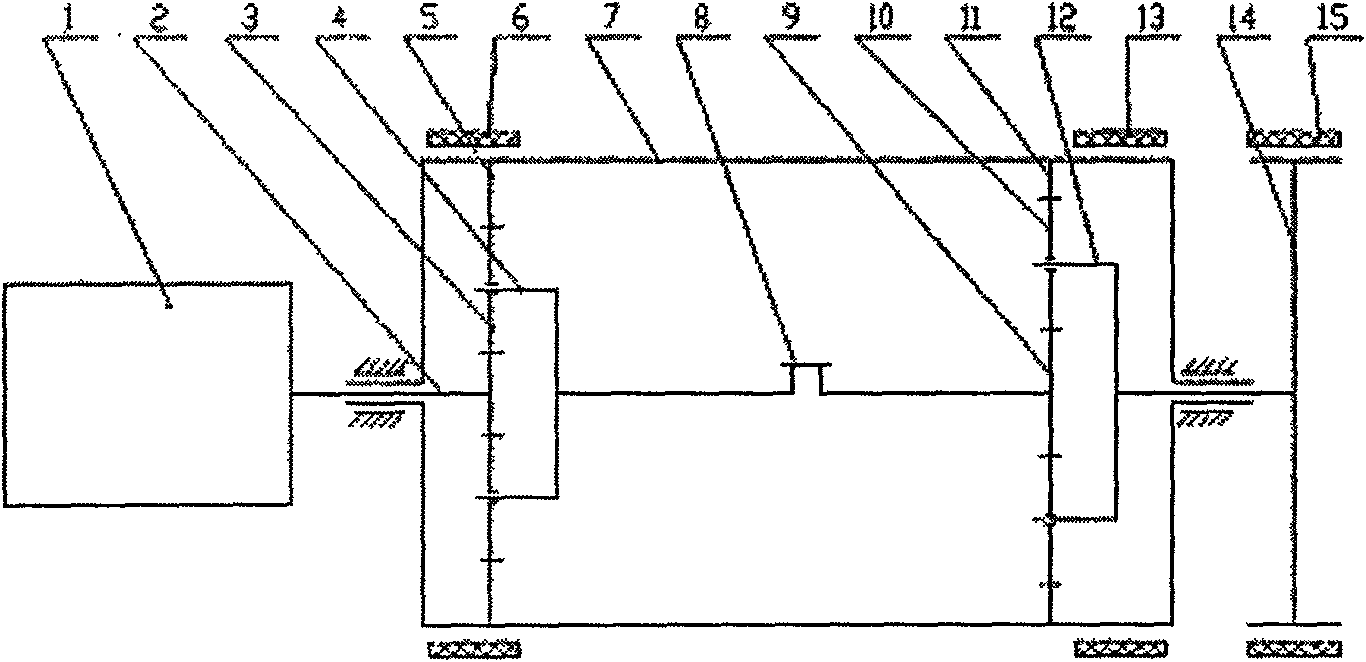

[0010] As shown in the attached drawing, the driving device of the mechanical winch with infinite rope speed regulation for mining mainly includes a double-speed electric motor 1 with equal power, a planetary reduction device, a driving drum 7, a safety brake 6, a working brake 13 and a clutch brake 15. mechanism. The equal-power two-speed motor 1 inputs power through the high-speed sun gear 2; the high-speed sun gear 2, the high-speed planetary gear 3, the high-speed planetary carrier 4 and the high-speed internal gear 5 form a first-stage reduction mechanism, and the high-speed planetary carrier 4 communicates with the The low-speed sun gear 9 is connected, the low-speed sun gear 9, the low-speed planetary gear 10, the low-speed planetary carrier 12 and the low-speed internal gear 11 form a two-stage reduction mechanism, wherein the high-speed internal gear 5 and the low-speed internal gear 11 are connected with the driving drum 7 as a whole, Finally, the power of the equal-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com