Nano material, preparation method thereof and quantum dot light-emitting diode

A technology of quantum dot luminescence and nanomaterials, which is applied in the field of quantum dot light-emitting devices, can solve the problems of device efficiency and life expectancy, and achieve the effects of suppressing Auger recombination, improving recombination efficiency, and life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

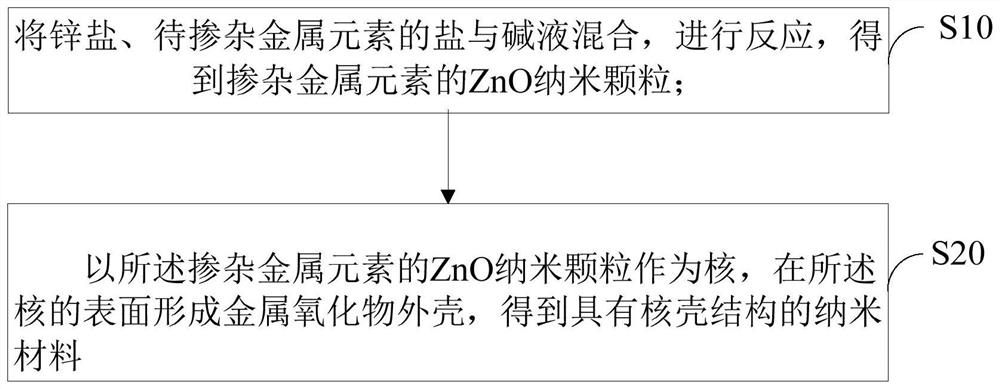

[0079] 1. Preparation of nanomaterials

[0080] 1) Add 10 mmol of tetramethylammonium hydroxide to 30 ml of 2-methoxyethanol, and heat in a water bath for 20 min;

[0081] 2), add 6mmol of zinc acetate and 2mmol of aluminum acetate, and stir for 3h to obtain a clear solution, and make aluminum-doped zinc oxide nanoparticles;

[0082] 3), then add 2mmol of aluminum acetate, ultrasonic 45min, and pause every 2min for 5s, wrap the upper shell on the nanoparticles, and obtain nanomaterials with a core-shell structure;

[0083] 4), washing the obtained nanomaterials with ethyl acetate and ethanol, and finally dissolving the nanomaterials in the ethanol solution.

[0084] 2. Preparation of quantum dot light-emitting diodes

[0085] 1) Evaporate ITO on the substrate as the first electrode, the thickness of ITO is 40nm, and then clean it with UVO (ultraviolet light ozone) for 15 minutes to improve the surface wettability while cleaning the surface;

[0086] 2) Spin-coat a layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com