Off-line quenched and tempered EH960 ultrahigh-strength maritime work steel plate and manufacturing method thereof

A manufacturing method and quenching and tempering technology, applied in the field of ship and marine engineering steel and its manufacturing, can solve the problems of large steel plate thickness and the need to improve the yield strength of the steel plate, and achieve the steel plate with suitable thickness, low crack sensitivity and high plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

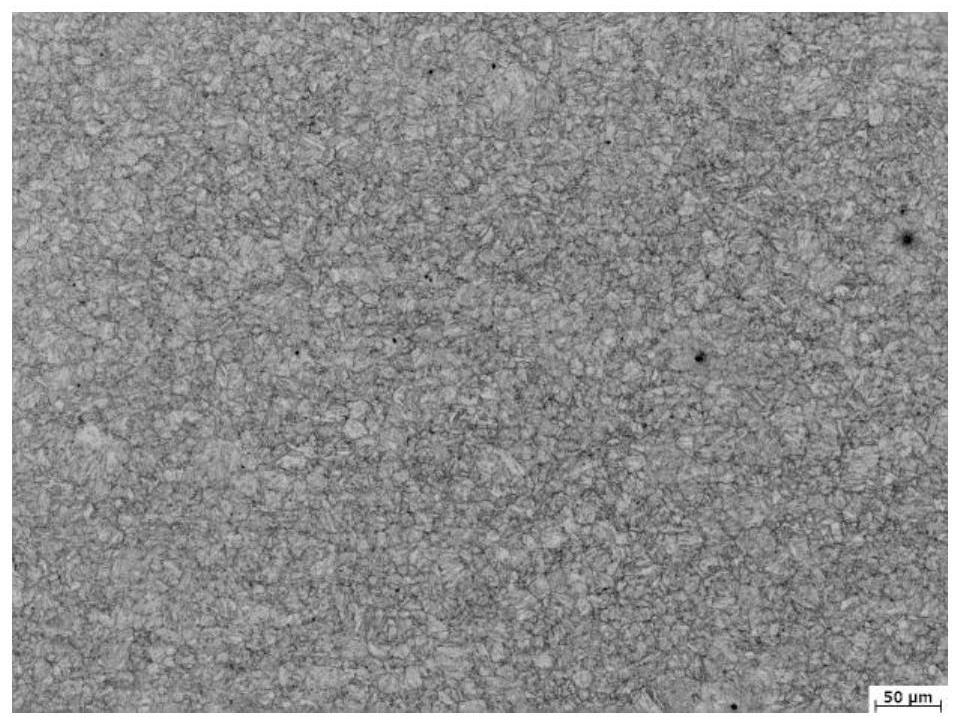

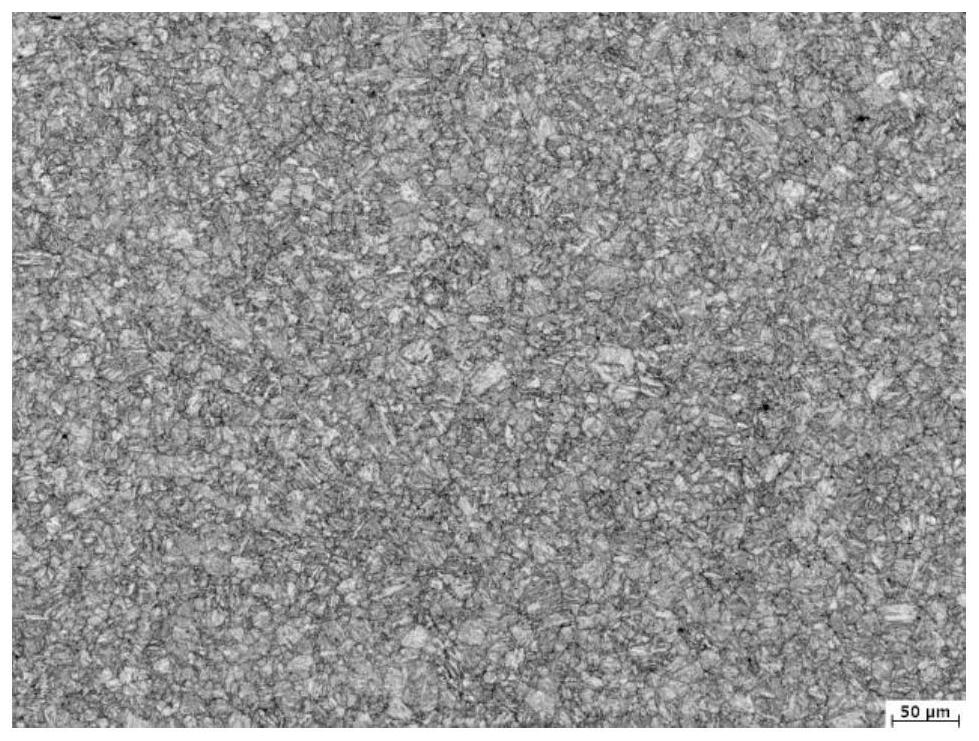

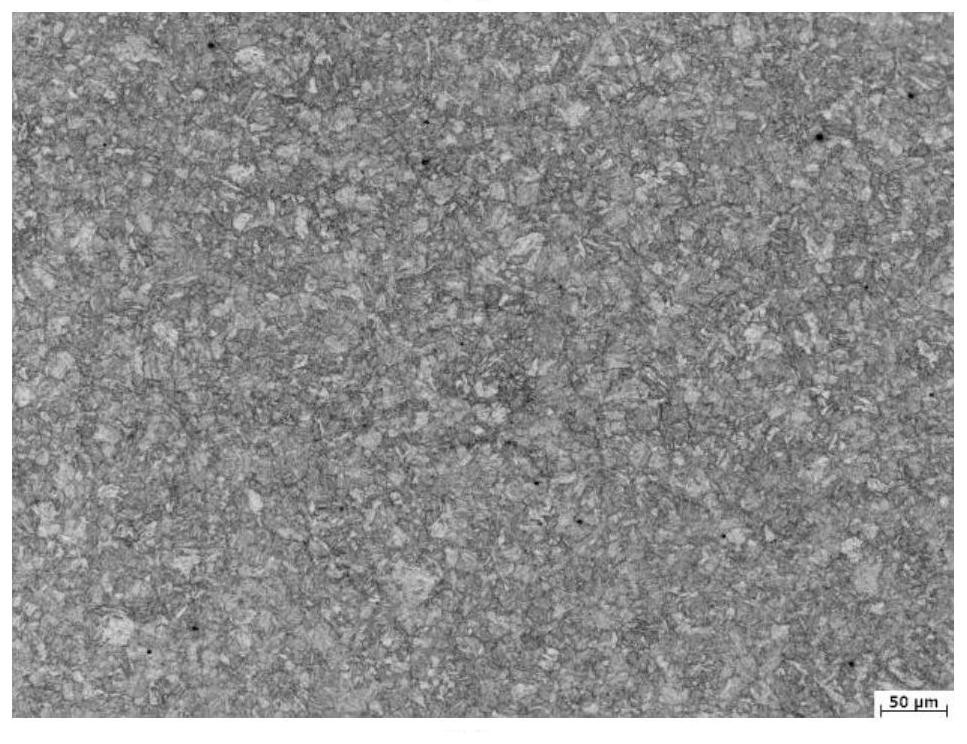

Image

Examples

Embodiment 1~3

[0021] The chemical composition of the EH960 ultra-high-strength marine steel plate in Examples 1-3 is shown in Table 1:

[0022] Table 1 Chemical composition of EH960 ultra-high-strength marine steel plate (wt,%)

[0023]

Embodiment 1

[0025] The production method of the 20mm thick EH960 ultra-high-strength marine steel plate embodiment of embodiment 1 is as follows:

[0026] Steelmaking and continuous casting process: target sulfur 0.001% after molten iron desulfurization; converter smelting adopts double slag method for dephosphorization; The alkalinity is 6; the holding time of vacuum treatment is 30 minutes; the seamless calcium line treatment is carried out after vacuum treatment, and the feeding line is 110 meters; The speed is stable at 0.75m / min, carbon-free covering agent is used, and Al (0.50%~0.60%) is used to customize mold flux.

[0027] Rolling process: controlled rolling process is adopted, which is two-stage rolling; the heating temperature of continuous casting slab before rolling is 1260°C; The final rolling temperature is 880°C, and the cumulative reduction rate of the last three passes is 32%. After rolling, it is air-cooled to room temperature and cooled without watering after rolling t...

Embodiment 2

[0029] The production method of the 60mm thick EH960 ultra-high-strength marine steel plate embodiment of embodiment 2 is as follows:

[0030] Steelmaking and continuous casting process: target sulfur 0.0015% after molten iron desulfurization; converter smelting adopts double slag method for dephosphorization, the drain hole is clean and free of defects, and the converter taps steel as slag; refining adopts white slag operation, white slag retention time is 35 minutes, the target The alkalinity is 7; the holding time of vacuum treatment is 30 minutes; the seamless calcium wire treatment is carried out after vacuum treatment, and the feeding line is 130 meters; Stable at 0.75m / min, using carbon-free covering agent, using Al (0.50% ~ 0.60%) custom mold flux.

[0031] Rolling process: controlled rolling process is adopted, which is two-stage rolling; the continuous casting slab heating temperature before rolling is 1200°C; the rough rolling temperature is 1080°C, high temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap