Self-assembled MXene/chitosan composite membrane as well as preparation method and application thereof

A technology of chitosan and composite film, which is applied in the direction of non-aqueous electrolyte battery electrodes, structural parts, electrical components, etc., can solve problems such as chapping, limit the application of secondary batteries, and fold a large number of self-supporting MXene films to increase wetting properties, inhibit the formation of metal dendrites, and reduce the effect of nucleation overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

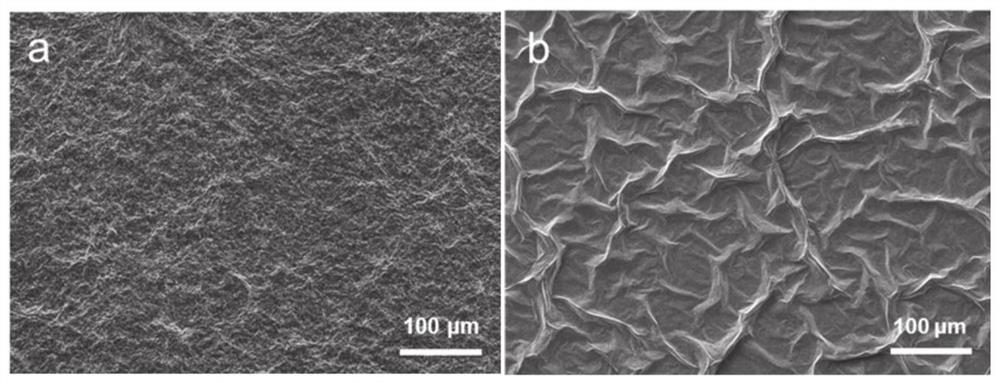

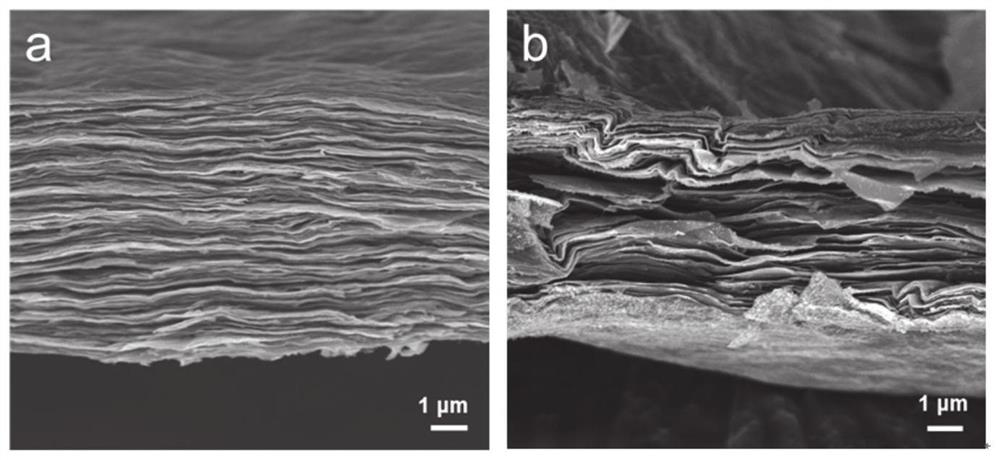

[0039] In one or more embodiments of the present invention, a method for preparing a self-assembled MXene / chitosan composite film includes: preparing MXene colloidal solution and chitosan solution, adding chitosan solution to few-layer MXene nano After the sheet colloidal solution is mixed evenly, the self-assembled composite membrane is obtained after suction filtration and drying; the MXene colloidal solution is an aqueous solution of few-layer MXene nanosheets, and the chitosan solution is an acid solution of chitosan.

[0040] Dissolving chitosan in acid to obtain an acid solution of chitosan is beneficial to the positive charge of the amine group in the chitosan molecule combined with the protons in the acid solution, and then self-assembles on the surface of the negatively charged MXene nanosheets. The acid is one of hydrochloric acid, formic acid, acetic acid, lactic acid, malic acid or ascorbic acid, preferably acetic acid. Reasonable acid concentration can promote the...

Embodiment 1

[0054] (1) Take 0.5gTi 3 AlC 2 Put the powder into a mixed solution of 0.5gLiF and 10mL of 6M hydrochloric acid, add 2.5mL of water, stir for 24h, centrifuge, wash to pH 6, and then ultrasonically peel off to obtain a few-layer MXene colloidal solution.

[0055] (2) Dissolving chitosan powder with a deacetylation degree of 90% in 1% acetic acid to form a solution with a chitosan mass fraction of 0.5%.

[0056] (3) Add the MXene colloidal solution of step (1) into the chitosan solution of step (2) and stir magnetically for 2 hours, and the mass ratio of MXene to chitosan is 10:1.

[0057] (4) After the solution mixed in the step (3) is filtered by suction and dried, the MXene / chitosan composite membrane is obtained.

[0058] (5) The MXene / chitosan composite film obtained in step (4) was used as the working electrode, the lithium metal foil was used as the counter electrode, and the ester electrolyte 1M LiPF6 EC / DEC (1:1, v / v, 10% FEC ) under an inert atmosphere, at 0.5mA cm ...

Embodiment 2

[0061] (1) Take 0.5gTi 3 AlC 2 Put the powder into a mixed solution of 0.5gLiF and 10mL of 6M hydrochloric acid, add 2.5mL of water, stir for 24h, centrifuge, wash to pH 6, and then ultrasonically peel off to obtain a few-layer MXene colloidal solution.

[0062] (2) Dissolving chitosan powder with a deacetylation degree of 90% in 1% acetic acid to form a solution with a chitosan mass fraction of 0.5%.

[0063] (3) Add the MXene colloidal solution of step (1) into the chitosan solution of step (2) and stir magnetically for 2 hours, and the mass ratio of MXene to chitosan is 10:1.

[0064] (4) After the solution mixed in the step (3) is filtered by suction and dried, the MXene / chitosan composite membrane is obtained.

[0065] (5) The MXene / chitosan composite film obtained in step (4) was used as the working electrode, the sodium metal foil was used as the counter electrode, and the ester electrolyte 1M NaPF6 EC / DEC (1:1, v / v, 5% FEC ) under an inert atmosphere, at 0.5mA cm -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com