High-rise building floor thickness measuring device and measuring method

A thickness measurement, high-rise building technology, applied in the direction of mechanical thickness measurement, etc., can solve the problems of inconvenience, reduce the convenience of measuring floor thickness, and affect the operation of inspectors to measure floor thickness, so as to reduce resistance and wear and reduce aperture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

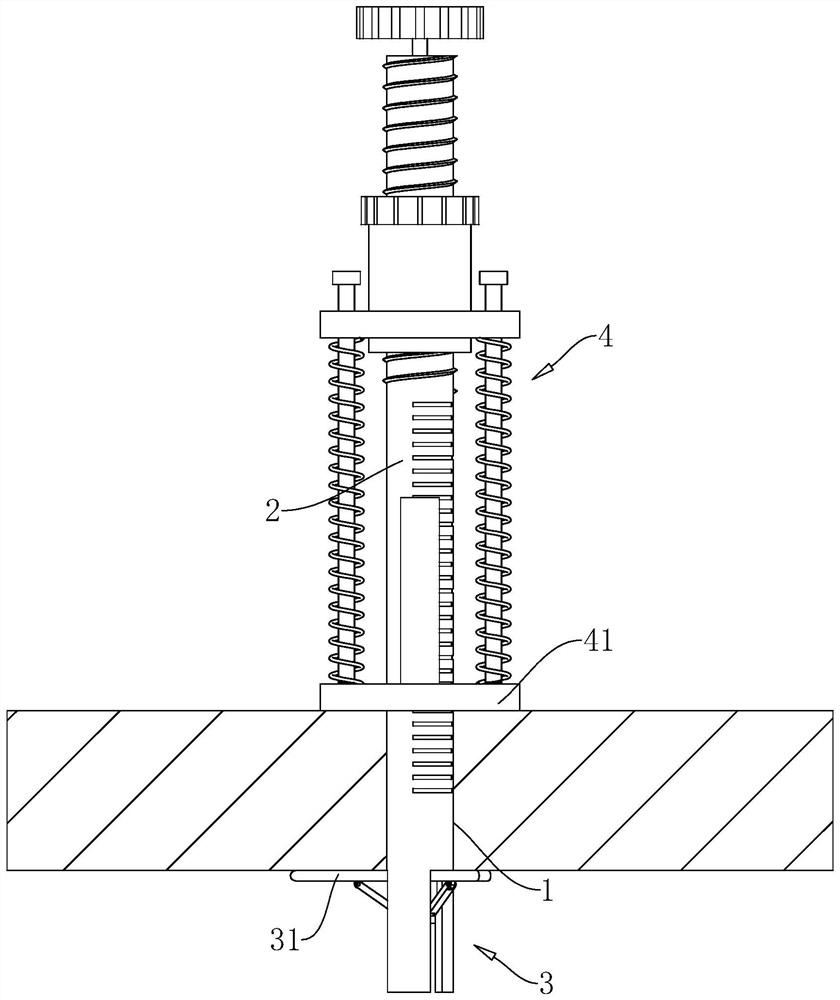

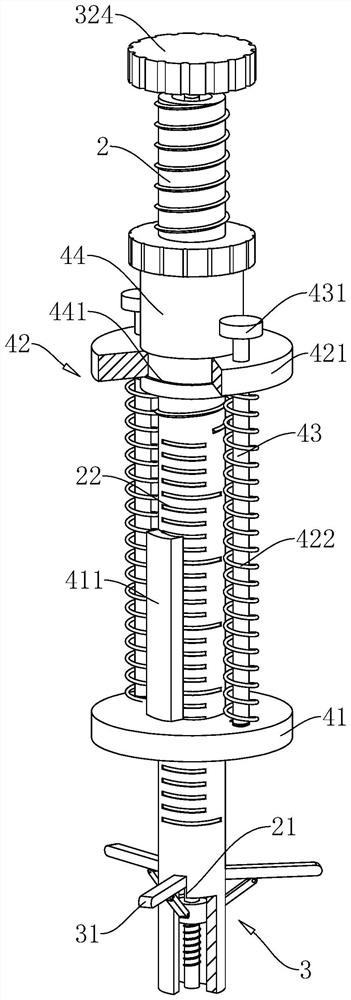

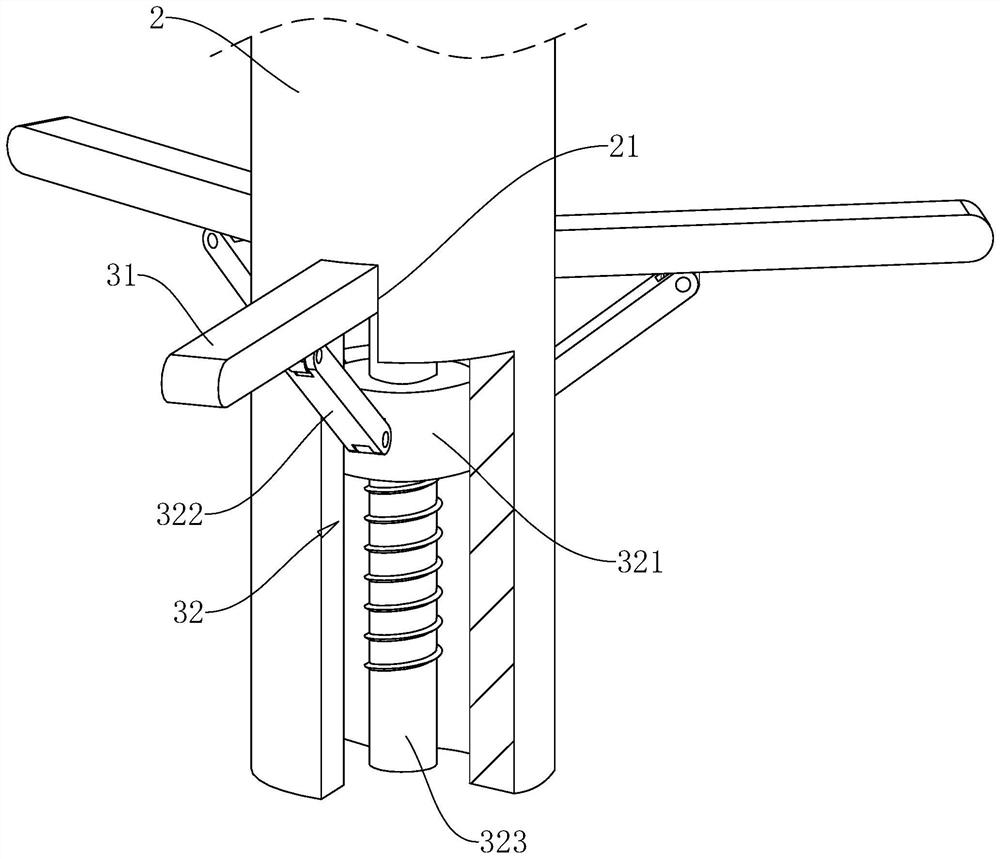

[0038] The following is attached Figure 1-3 The application is described in further detail.

[0039] The embodiment of the present application discloses a device for measuring the thickness of a high-rise building floor. refer to figure 1 , the measuring device comprises an installation pipe 2 with a circular cross-section, and the installation pipe 2 is provided with a clamp assembly 3 and an abutment assembly 4, the clamp assembly 3 includes a clamp rod 31 arranged at one end of the installation pipe 2, and the abutment The assembly 4 includes an abutment plate 41 sheathed on the installation pipe 2 . A measurement hole 1 for the installation pipe 2 to pass through is opened on the floor in advance, and the clamping rod 31 is used to abut against the bottom surface of the floor after the installation pipe 2 passes through the measurement hole 1, and the abutment disc 41 is used to abut against the top surface of the floor. Then, the clamping rod 31 and the abutment plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com