Quick mounting building and mounting method thereof

A construction and quick installation technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of self-heavy components, poor seismic resistance, and difficult assembly, and achieve strong node support, fast and stable connection, and installation speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

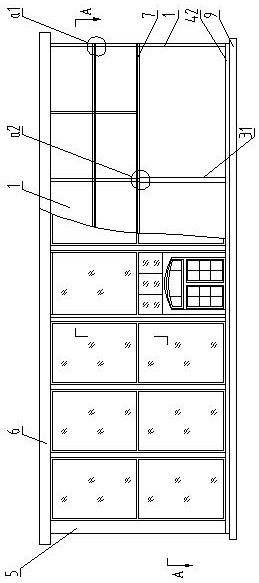

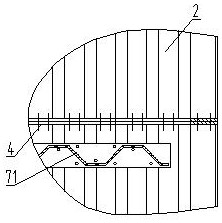

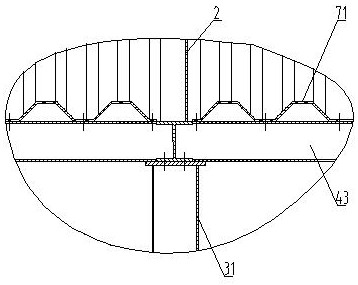

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the composition of the quick-installation building of the present invention includes: a quick-installation wallboard 1, the quick-installation wallboard 1 includes a corrugated board 2, the two sides of the corrugated board are bent to form a connecting column 3, and the described The upper end and the lower end of the corrugated plate have end beams 4 or the upper and lower ends of the corrugated plate are connected with beams 41 . The horizontally adjacent quick-install wall panels 1 are assembled and connected by the connecting column during installation. The cross-section of the connecting column is groove-shaped, and the three sides of the groove-shaped connecting column are combined to form a linear wall. 51 or L-shaped body of wall 52 or T-shaped body of wall 53 or cross-shaped body of wall 54, after being assembled and connected together constitute building wall body 5, the design of groove-shaped ...

Embodiment 2

[0045] In the quick-installation building described in Embodiment 1, the quick-installation wallboard is a plane quick-installation wallboard, a right-angle quick-installation wallboard 11 or an arc-shaped quick-installation wallboard, and the middle part of the corrugated board is bent to form the Right-angle quick-loading wall panels 11. Such as Figure 5 , Figure 9 The adjacent planar quick-install wallboards shown are horizontally connected to form a linear wall body 51 .

Embodiment 3

[0047] The fast-packing building described in embodiment 1 or 2, such as Figure 5 , Figure 6 Figure 7 , Figure 8 , Figure 10 As shown, different wall parts are formed by different combinations of three sides of the groove-shaped connecting column, and the four adjacent quick-installed wall panels 1 are assembled and connected by the connecting column 3 to form the cross-shaped The wall 54, or the two flat quick-install wall panels and one right-angle quick-install wall panel 11 are connected by the right-angle side formed by bending the right-angle quick-install wall panel 11 through the connecting column 3 Body columns are assembled and connected to form the cross-shaped wall; three right-angled adjacent quick-install wall panels 1 are assembled and connected through the connecting column 3 to form the T-shaped wall, or one of the The plane quick-installation wallboard and one of the right-angle quick-installation wallboards are assembled and connected by the right-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com