Near-infrared light-emitting material, preparation method and light-emitting device

A technology of light-emitting materials and light-emitting devices, applied in the directions of light-emitting materials, semiconductor devices, chemical instruments and methods, etc., can solve the problems of small spectral coverage, narrow half-peak width, etc., and achieve wide wavelength coverage, wide half-peak width, The effect of strong luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A second aspect of the embodiments of the present application provides a method for preparing a near-infrared light-emitting material, and the preparation method includes the following steps:

[0050] S01: Chemical formula A of the above-mentioned near-infrared light-emitting material according to the embodiment of the present application x D y O 4 :R m The compound raw materials of each element are weighed in the stoichiometric ratio, and then ground to obtain the raw material mixture;

[0051] S02: sintering the raw material mixture to obtain a near-infrared light-emitting material.

[0052] The preparation method of the near-infrared light-emitting material provided by the embodiments of the present application is simple in process, easy to obtain raw materials, and the finally prepared near-infrared light-emitting material has a long fluorescence lifetime, and has the characteristics of wide wavelength coverage, wide half-peak width and strong luminous intensity ...

Embodiment 1

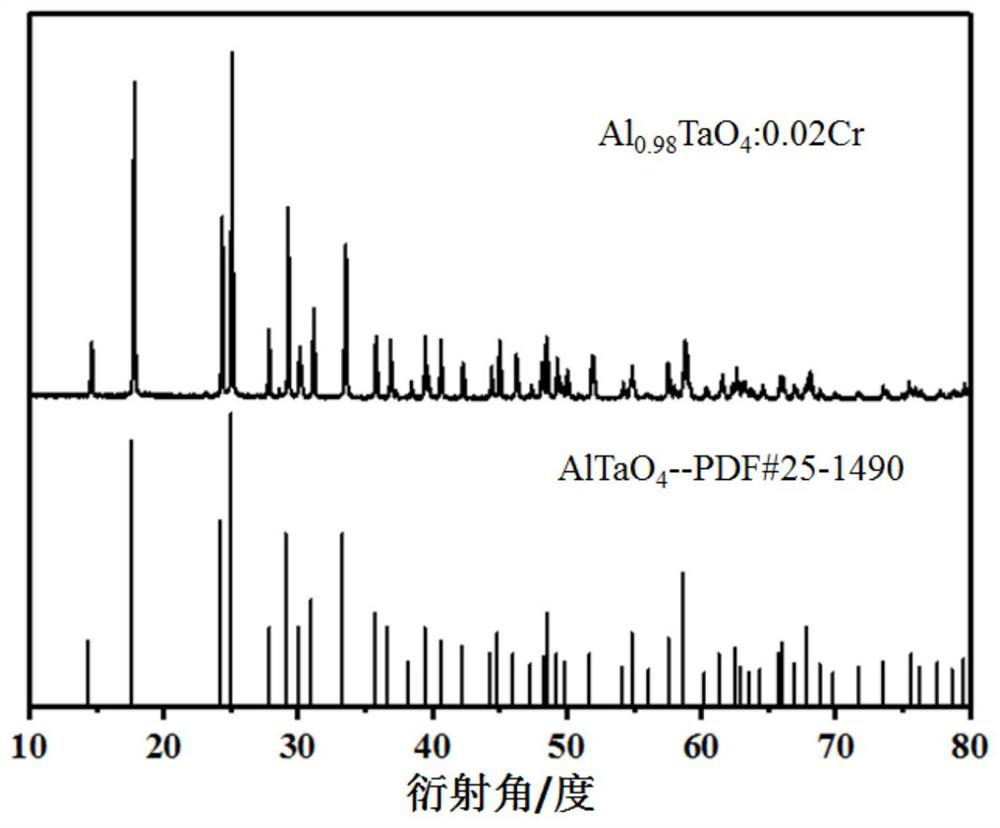

[0065] This embodiment provides a broadband emitting near-infrared light-emitting material, and the compound formula is Al 0.98 TaO 4 : 0.02Cr. The preparation method includes the following steps:

[0066] According to the chemical formula Al 0.98 TaO 4 : Stoichiometric ratio of 0.02Cr, accurate weighing of Al 2 O 3 , Ta 2 O 5 , Cr 2 O 3 The raw materials are placed in the grinding, and after grinding for 30 minutes, they are transferred into an alumina crucible, sintered at 1450 °C for 6 hours in a high-temperature furnace air atmosphere, and cooled to room temperature with the furnace. Finally, a broadband near-infrared luminescent material with relatively uniform particle size is obtained.

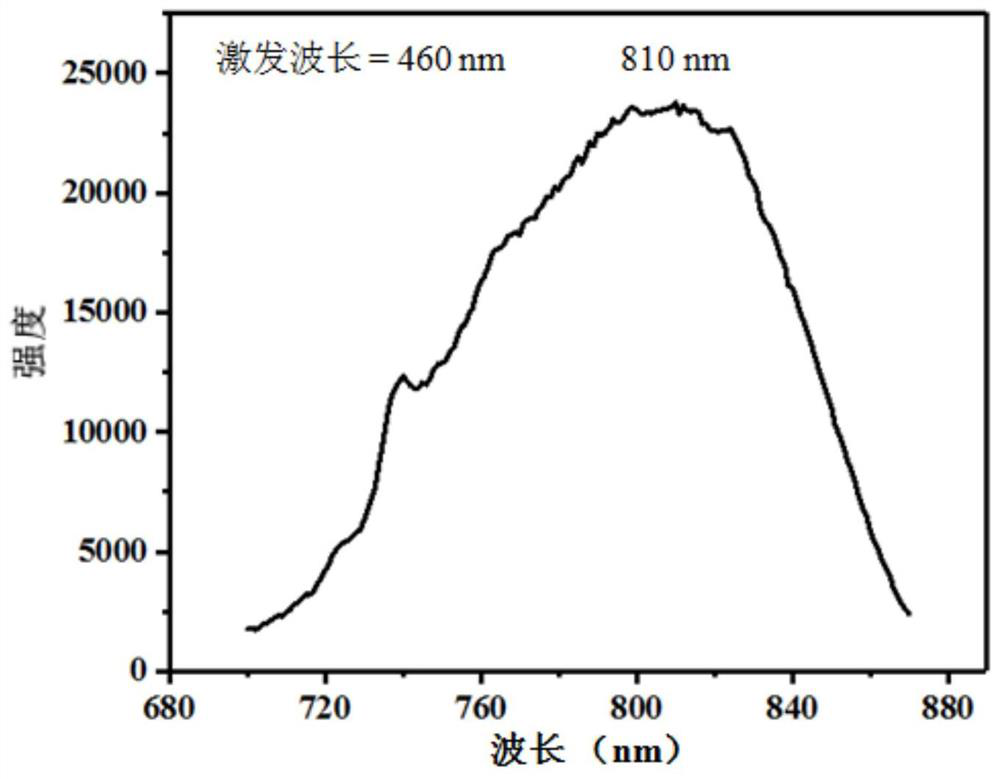

[0067] The luminescent material obtained in this example is characterized and analyzed by a fluorescence spectrometer, and its emission spectrum is obtained under excitation at 460 nm, such as figure 1 As shown, the peak wavelength of the emission spectrum is 810 nm, and the ...

Embodiment 2

[0069] This embodiment provides a broadband emitting near-infrared light-emitting material, and the compound formula is Al 0.992 NbO 4 : 0.008Cr. The preparation method includes the following steps:

[0070] According to the chemical formula Al 0.992 NbO 4 : Stoichiometric ratio of 0.008Cr, accurate weighing of Al 2 O 3 , Nb 2 O 5 , Cr 2 O 3 The raw materials are placed in the grinding, and after grinding for 30 minutes, they are transferred into an alumina crucible, sintered at 1400 °C for 6 hours in a high-temperature furnace air atmosphere, and cooled to room temperature with the furnace. Finally, a broadband near-infrared luminescent material with relatively uniform particle size is obtained.

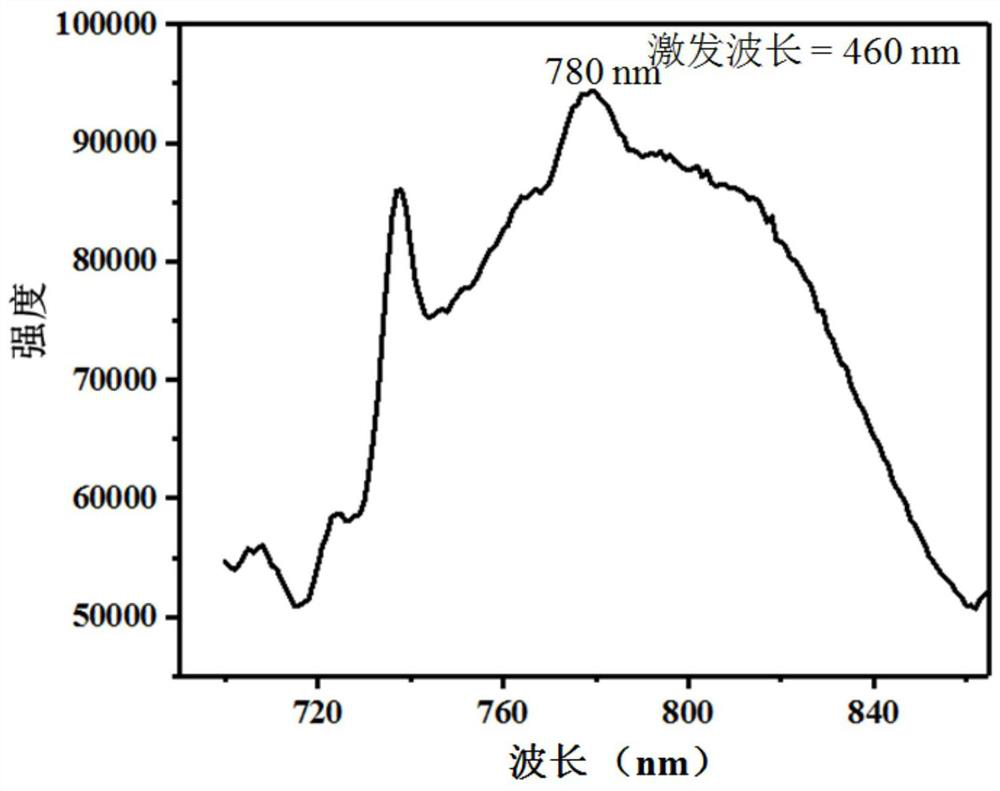

[0071]The luminescent material obtained in this example was characterized and analyzed by a fluorescence spectrometer, and its emission spectrum was obtained under excitation at 460 nm, as shown in the following figure: image 3 As shown, the peak wavelength of the emissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com