Waterborne epoxy anticorrosive coating for inner wall of petroleum storage tank in medium environment and preparation method of waterborne epoxy anticorrosive coating

A technology for epoxy anti-corrosion coatings and petroleum storage tanks, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of chemical resistance, wear resistance, hardness, water resistance Not easy to cure, slow drying speed, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

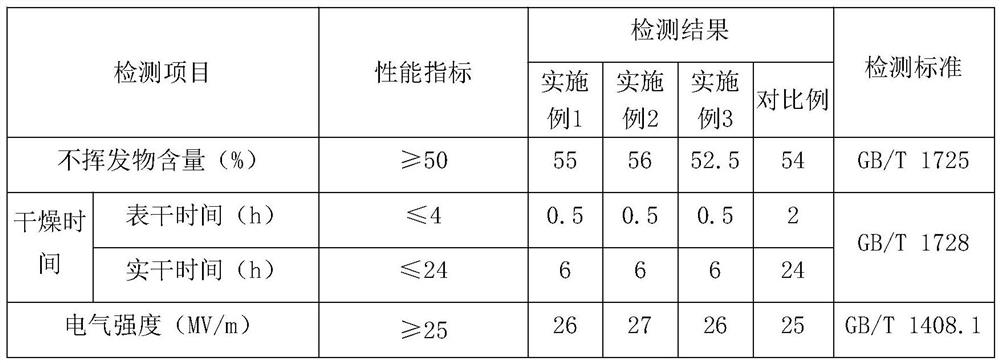

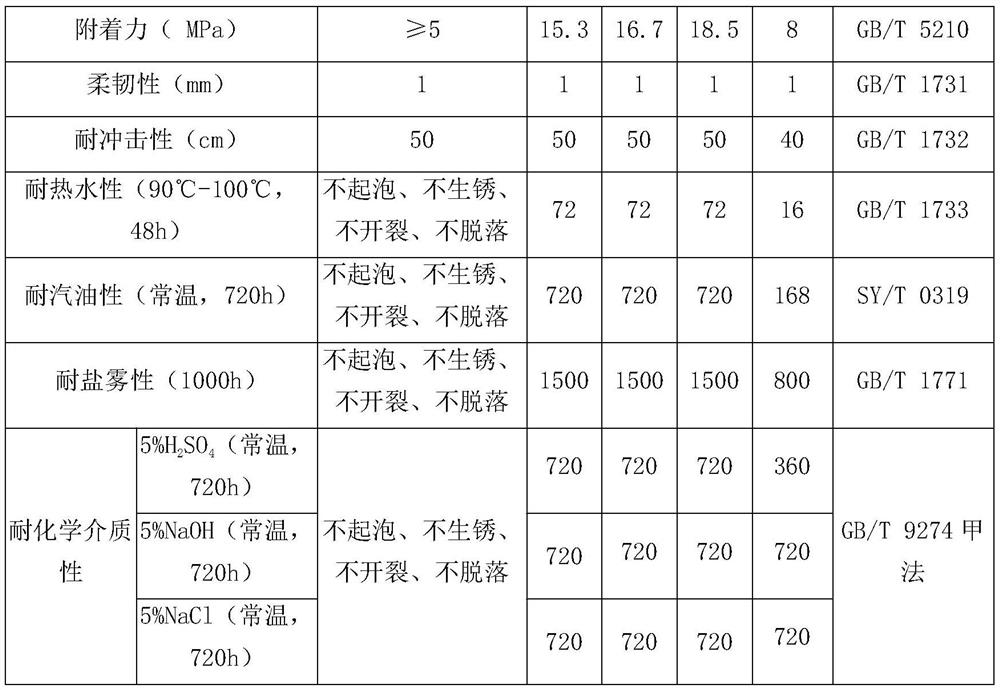

Examples

Embodiment 1

[0047] A preparation method of water-based epoxy anticorrosion coating in the medium environment of the inner wall of an oil storage tank, comprising the following steps:

[0048] Step 1, modification of hexagonal boron nitride powder

[0049] The hexagonal boron nitride powder was fully dried in an oven at 110°C for 8 hours, and the temperature dropped to room temperature before use.

[0050] 1 part by weight of the treated hexagonal boron nitride powder and 100 parts by weight of a 50% carbonamide ethanol solution were stirred at 80° C. for 24 hours at high speed, and then naturally cooled to room temperature. Put the treatment solution in a centrifuge, centrifuge the treated hexagonal boron nitride, wash it several times, and dry it in an oven at 110°C for 8 hours. After the temperature drops to room temperature, the pretreated hexagonal boron nitride is obtained. Boron powder, spare.

[0051] Place the pretreated hexagonal boron nitride powder in 5% aminosiloxane ethanol...

Embodiment 2

[0060] A preparation method of water-based epoxy anticorrosion coating in the medium environment of the inner wall of an oil storage tank, comprising the following steps:

[0061] Step 1, modification of hexagonal boron nitride powder

[0062] The hexagonal boron nitride powder was fully dried in an oven at 110°C for 8 hours, and the temperature dropped to room temperature before use.

[0063] 3 parts by weight of the treated hexagonal boron nitride powder and 100 parts by weight of a 50% carbonamide ethanol solution were stirred at 80° C. for 24 hours at high speed, and cooled naturally to room temperature. Put the treatment solution in a centrifuge, centrifuge the treated hexagonal boron nitride, wash it several times, and dry it in an oven at 110°C for 8 hours. After the temperature drops to room temperature, the pretreated hexagonal boron nitride is obtained. Boron powder, spare.

[0064] Place the pretreated hexagonal boron nitride powder in 5% aminosiloxane ethanol sol...

Embodiment 3

[0072] A kind of preparation method of water-based epoxy anticorrosion coating under the medium environment of the inner wall of petroleum storage tank, comprises the following steps:

[0073] Step 1, modification of hexagonal boron nitride powder

[0074] The hexagonal boron nitride powder was fully dried in an oven at 110°C for 8 hours, and the temperature dropped to room temperature before use.

[0075] 2 parts by weight of the treated hexagonal boron nitride powder and 100 parts by weight of a 50% carbonamide ethanol solution were stirred at 80° C. for 24 hours at high speed, and then naturally cooled to room temperature. Put the treatment solution in a centrifuge, centrifuge the treated hexagonal boron nitride, wash it several times, and dry it in an oven at 110°C for 8 hours. After the temperature drops to room temperature, the pretreated hexagonal boron nitride is obtained. Boron powder, spare.

[0076] Place the pretreated hexagonal boron nitride powder in 5% aminosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com